2 |

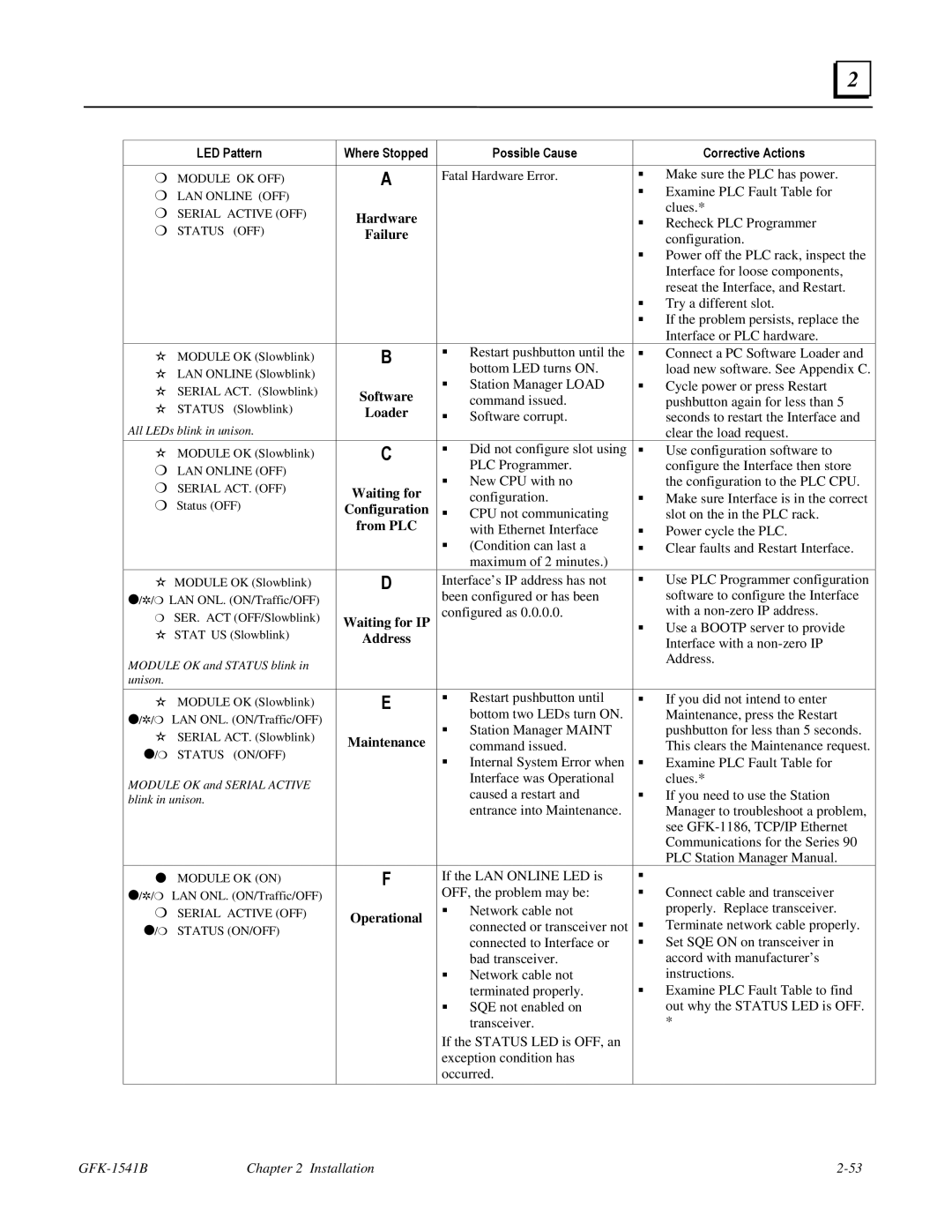

| LED Pattern | Where Stopped |

| Possible Cause |

| Corrective Actions | |

|

|

|

|

| |||

❍ MODULE OK OFF) | A | Fatal Hardware Error. | | Make sure the PLC has power. | |||

❍ | LAN ONLINE (OFF) |

|

|

| Examine PLC Fault Table for | ||

|

|

|

| clues.* | |||

❍ | SERIAL ACTIVE (OFF) | Hardware |

|

|

| ||

|

| | Recheck PLC Programmer | ||||

❍ | STATUS (OFF) |

|

| ||||

Failure |

|

| |||||

|

|

| configuration. | ||||

|

|

|

|

|

| ||

|

|

|

|

| Power off the PLC rack, inspect the | ||

|

|

|

|

|

| Interface for loose components, | |

|

|

|

|

|

| reseat the Interface, and Restart. | |

|

|

|

|

| Try a different slot. | ||

|

|

|

|

| If the problem persists, replace the | ||

|

|

|

|

|

| Interface or PLC hardware. | |

✫ MODULE OK (Slowblink) | B | | Restart pushbutton until the | | Connect a PC Software Loader and | ||

✫ | LAN ONLINE (Slowblink) |

| | bottom LED turns ON. |

| load new software. See Appendix C. | |

| Station Manager LOAD | | Cycle power or press Restart | ||||

✫ | SERIAL ACT. (Slowblink) | Software | |||||

| command issued. |

| pushbutton again for less than 5 | ||||

✫ | STATUS (Slowblink) |

|

| ||||

Loader | |

| |||||

Software corrupt. |

| seconds to restart the Interface and | |||||

All LEDs blink in unison. |

|

| |||||

|

|

|

| clear the load request. | |||

✫ MODULE OK (Slowblink) | C | | Did not configure slot using | | Use configuration software to | ||

❍ | LAN ONLINE (OFF) |

|

| PLC Programmer. |

| configure the Interface then store | |

| New CPU with no |

| the configuration to the PLC CPU. | ||||

❍ | SERIAL ACT. (OFF) | Waiting for |

| ||||

| configuration. | | Make sure Interface is in the correct | ||||

❍ | Status (OFF) |

| |||||

Configuration | | ||||||

CPU not communicating |

| slot on the in the PLC rack. | |||||

|

|

| |||||

|

| from PLC |

| with Ethernet Interface | | Power cycle the PLC. | |

|

|

|

| ||||

|

|

| (Condition can last a | | Clear faults and Restart Interface. | ||

|

|

|

| maximum of 2 minutes.) |

|

| |

✫ | MODULE OK (Slowblink) | D | Interface’s IP address has not | Use PLC Programmer configuration | |||

| software to configure the Interface | ||||||

●/✲/❍ LAN ONL. (ON/Traffic/OFF) |

| been configured or has been |

| ||||

❍ | SER. ACT (OFF/Slowblink) | Waiting for IP | configured as 0.0.0.0. |

| with a | ||

|

| Use a BOOTP server to provide | |||||

✫ | STAT US (Slowblink) |

|

| ||||

Address |

|

| |||||

|

|

| Interface with a | ||||

|

|

|

|

|

| ||

MODULE OK and STATUS blink in |

|

|

|

| Address. | ||

|

|

|

|

| |||

unison. |

|

|

|

|

|

| |

|

|

|

|

|

| ||

✫ MODULE OK (Slowblink) | E | | Restart pushbutton until | | If you did not intend to enter | ||

●/✲/❍ | LAN ONL. (ON/Traffic/OFF) |

| | bottom two LEDs turn ON. |

| Maintenance, press the Restart | |

| Station Manager MAINT |

| pushbutton for less than 5 seconds. | ||||

✫ | SERIAL ACT. (Slowblink) | Maintenance |

| ||||

| command issued. |

| This clears the Maintenance request. | ||||

●/❍ STATUS (ON/OFF) |

|

| |||||

| Internal System Error when | | Examine PLC Fault Table for | ||||

|

|

| |||||

MODULE OK and SERIAL ACTIVE |

|

| Interface was Operational |

| clues.* | ||

|

| caused a restart and | | If you need to use the Station | |||

blink in unison. |

|

| |||||

|

|

|

| entrance into Maintenance. |

| Manager to troubleshoot a problem, | |

|

|

|

|

|

| see | |

|

|

|

|

|

| Communications for the Series 90 | |

|

|

|

|

|

| PLC Station Manager Manual. | |

● | MODULE OK (ON) | F | If the LAN ONLINE LED is | |

| ||

|

| ||||||

●/✲/❍ LAN ONL. (ON/Traffic/OFF) |

| OFF, the problem may be: | Connect cable and transceiver | ||||

❍ | SERIAL ACTIVE (OFF) | Operational | | Network cable not | | properly. Replace transceiver. | |

●/❍ STATUS (ON/OFF) |

| connected or transceiver not | Terminate network cable properly. | ||||

|

| ||||||

|

|

|

| connected to Interface or | | Set SQE ON on transceiver in | |

|

|

|

| bad transceiver. |

| accord with manufacturer’s | |

|

|

| | Network cable not | | instructions. | |

|

|

|

| terminated properly. | Examine PLC Fault Table to find | ||

|

|

| SQE not enabled on |

| out why the STATUS LED is OFF. | ||

|

|

|

| transceiver. |

| * | |

|

|

| If the STATUS LED is OFF, an |

|

| ||

|

|

| exception condition has |

|

| ||

|

|

| occurred. |

|

| ||

|

|

|

|

|

|

| |

Chapter 2 Installation |