Application Manual

Page

Limited Warranty and Imitation of Liability

Page

Safety Precautions

Required

Prohibited

Page

Table of Contents

Input/Output Setting

High-Speed Counter Single-Phase

High-Speed Counter Two-Phase Counter

Memory Size and Memory Assignment

Connecting to the Ports

Syntax and Assembler Error Codes

Operation Error Codes

Error Display and Actions

Memo

Remote maintenance through modem connection

Easily adjustable potentiometer

Maintaining programs without a battery

Compliant with overseas specifications as standard

Memo

System Overview

23,28-point type system configuration diagram

Device name Description

Chapter Function and Performance Specifications

General Specifications

Function Specifications

Timer counter is provided internally

Device that has been connected

WR, DR

Off to stop operation

Is running, operation stops and the outputs are aborted OFF

General purpose port

R7EC

Interrupt input

Performance Specifications

Calculation Specifications

Input Specifications

Circuit diagram

Specification

OFF → on

Output Specifications

Y100 of EH-*23DRP/A23DRT/*28DRP/*28DRT

Output specification

Ms max 24 V DC 0.2A

Load current Common Output

Ms max 24 V DC 0.2A Response time

Number of output points See Chapter Number of common

Maximum Circuit Load current Common Output

Externally supplied power

Ms max

Maximum Circuit A 240 V AC Load current Common

At 1 cycle or less/common

High-Speed Counter Specifications

PWM Output/Pulse Train Output Specifications

Analogue Input Specifications

Point and 28-point type 10/14/28-point Relay Output

Analogue Output Specifications

Circuit diagram 23 points type

Circuit diagram Analog expansion unit

Module type Points type module Analog exp. unit

Potentiometer Analogue Input Specifications

Interrupt Input Specifications

Backup

Expansion

Clock Function

Power Supply for Sensor

Product lineup

Others Model

Detailed explanation Remarks

10-Point Basic Unit

Name and function of each part Type

14-Point Basic Unit

EH-*14

To the right

23-Point and 28-Point Basic Unit

EH-*23 EH-*28

Expansion Unit

Name and function of each part

RUN

Terminal Layout and Wiring

Power supply 24V DC Load power supply 24V DC 100-240V AC

AC power supply 100-240V AC Load power supply 24V DC

DC power supply 24V DC

AC power supply

Input

Power supply 24V DC 12/24V DC

Power supply 24V DC Output Load power supply 12/24V DC

Power supply 24V DC

Output Load power supply 12/24V DC

WRF06E

Power supply 24V DC Output

Output Power supply 100-240V AC

Output Power supply 24V DC

24V DC 12/24V DC

Output Power supply

100-240V AC Input Output

Input Output Power supply 100-240V AC

Load power supply 24V DC, 100-240V AC Output

EH-D6EAN Example of current input and current output

Current input ⋅

IO6 OC7 VO7

OC6 VO6 IO7

100V AC 264V AC 24V DC Normal Rush

Weights and Power Consumption

Type Weight

Exterior Dimensions

140 150

Memo

Instruction classification table Description Type

Instruction Classifications

List of Instructions

TD, SS, CU, CT

Nand

TD, SS, CU CTU, CTD, CL

RES

Basic instructions timer, counter

DX, DY, DR

Basic instructions relational box

WX, WY, WR

Item number Ladder symbol Instruction symbol

WR, WM

BCD

DR, DM

Number

Instruction symbol Process descriptions

Instruction symbol Process descriptions Name

WY, WR, WM

WM, TC

Processing time when n=1

BCD →

FUN instructions

PWM

BOX

Instruction Specification Details

Item number

Ladder format Condition code

Remark

Bit Word Double word Constant Usable I/O

ANI

Basic instructions-3

Contact serial connection AND, ANI

Basic instructions-5

Contact parallel connection OR, ORI

Condition

ORI

Basic instructions-7

Negation not

Instruction format

Not

Basic instructions-8

Leading edge detection and DIF, or DIF

DIF n

Number To 511 Decimal

DFN n

Basic instructions-9

Trailing edge detection and DFN, or DFN

Bit Word Double word

Usable I/O Other

WX WY WM DX DY TD, SS

Usable I/O Bit

Word Double word Constant Other

Set start/reset cancel master control MCS, MCR

Basic instructions-13

Remark

Upper case MCS

Ladder format

MPS

MRD

MPP

See Function column

Basic instructions-18

Logical block serial connection ANB

Basic instructions-19

Logical block parallel connection ORB

Basic instructions-20

Processing box start and end Processing BOX

Bit Word

Indicates the start and end of the processing box

Function Indicates the start and end of the relational box

Basic instructions-21

Relational box start and end Relational BOX

OUT TD n t s

On delay timer on Delay Timer

Basic instructions-22

Time chart

Basic instructions-23

Single shot Single Shot

OUT SS n t s

TMR, CU

SS11 turns off when set value ≥ progress value

Progress value is updated

Conditions are ignored because it uses edge trigger

SS11 is turned on at the leading edge of X00001 again,

Basic instructions-24

Counter Counter

OUT CU n s

Counter number To 255 Decimal Set value To 65535 Decimal

Ignored X00005 CL15 CU15 Set value Progress Value CU15 TC15

UP/DOWN Counter

CTU17

Basic instructions-27

Counter clear Counter Clear

OUT CL n s

Counter number To 255 Decimal

Word Double word

Double word LD, and s1S==s2 Or s1S==s2

Command format

Condition Steps

When WR0000 ≠ WR0002, R003 turns on

Basic instructions-30

Relational box Relational BOX

26.8 Lower case DW

BOX

Double word LD, and s1Ss2 Or s1Ss2

When WR0000 WR0002, R005 turns on

Basic instructions-32

Word See Notes 37.5 Double word

S1 s2 Steps

When DR0000 DR0002, R006 turns on signed

Basic instructions-33

SignedRelational box Signed Relational BOX

Off

When WR0000 ≤ WR0002, R007 turns on

Basic instructions-34

≤ Relational box ≤ Relational BOX

S1 = s2

Double word LD, and s1S=s2 Or s1S=s2

Arithmetic instructions-1

Substitution statement Assignment Statement

= s

See following table

Designated by WR0000 + WM000

X00001

Substituted into WR0000 at the leading edge of input

Arithmetic instructions-2

Binary addition Binary Addition

Word Double word

Substitution destination Augend Addend

Word 177 Double word

Arithmetic instructions-3

115 Lower case DW

Arithmetic instructions-4

Binary subtraction Binary Subtraction

Substitution destination Minuend Subtrahend

Positive Negative

Arithmetic instructions-5

BCD subtraction BCD Subtraction

104 Lower case DW

Word 163 Double word

Arithmetic instructions-6

Binary multiplication Binary Multiplication

Word 112 Double word

Substitution destination Multiplicand Multiplier

Arithmetic instructions-7

BCD multiplication BCD Multiplication

164 Lower case DW

Word 447 Double word

Multiplication

Signed binary multiplication Signed Binary

143

Arithmetic instructions-9

Binary division Binary Division

= s1 / s2

= s1 / s2 Word 110 Double word

Arithmetic instructions-10

BCD division

= s1 B/ s2

152 Lower case DW

Arithmetic instructions-11

Signed binary division

= s1 S/ s2

101

Arithmetic instructions-12

Logical or

= s1 or s2

Upper case B

Arithmetic instructions-13

Logical

= s1 and s2

= s1 and s2 Bit, word Double word

Arithmetic instructions-14

Exclusive or

= s1 XOR s2

= s1 XOR s2 Bit, word Double word

Arithmetic instructions-15

= Relational expression

= s1 == s2

= s1 == s2 Is a word Is a double word

Signed = Relational expression

= s1 S== s2

108

= s1 S== s2 Is a double word

= s1 s2 Is a word Is a double Word Bit Double word

Arithmetic instructions-17

= s1 s2

= s1 S s2 Is a double word

Signed Relational expression

= s1 S s2

Arithmetic instructions-19

= s1 s2 Is a word Is a double word

Arithmetic instructions-20

Arithmetic instructions-21

≤ Relational expression

= s1 = s2

= s1 = s2 Is a word Is a double word

= s1 S= s2 Is a double word

Signed ≤ Relational expression

= s1 S= s2

Application instructions-1

Bit set

Bset d, n

Bit location to be set Constant is set Decimal

Bres d, n

Bit reset

Application instructions-2

BTS d, n

Application instructions-3

Bit test

Also, the 20th bit of DR0102 is reset to 0 by Bres

Also, the 20th bit of DR0104 is checked by BTS

Application instructions-4

Shift right

SHR d, n

After execution

DIF1

SHL d, n

Application instructions-5

Shift left

ROR d, n

Application instructions-6

Rotate right

ROL d, n

Application instructions-7

Rotate left

B31 DR0002

LSR d, n

Application instructions-8

Logical shift right

Application instructions-9

Logical shift left

LSL d, n

If d is a word

BSR d, n

Application instructions-10

BCD shift right

BSL d, n

Application instructions-11

BCD shift left

Application instructions-12

Block transfer Move

Below

If n is a word

Words of data are transferred

Application instructions-13

Copy

Copy d, s, n

Below Copy d, s, n

Default value H2020 is set in the range of WR0100 to WR01FE

Application instructions-14

Block exchange Exchange

R7F4 R7F3 R7F2 R7F1

XCG d1, d2, n

To be reversed

Reverses the contents of d

Application instructions-15

Application instructions-16

Twos complement Negate

NEG d

To take complement

Application instructions-17

Absolute value

ABS d, s

ABS d, s Word Double word

Application instructions-18

Binary → BCD conversion

Before conversion

BIN

Application instructions-19

BCD → Binary conversion

After conversion BIN Before conversion

BCD

Application instructions-20

Decode

Average

105 115 195 317 481 829 1586

128 187 126

Application instructions-21

Encode

Number of bits set to That counts the bits Set to

Application instructions-22

Bit count

Application instructions-23

Swap

Swap d

Swaps the upper 8 bits and lower 8 bits contained in d

When n=0, it is not executed When n5, it is not executed

Application instructions-24

Unit

Unity result write Destination I/O

Input Point type Output

Distribute

When n=0, it is not executed

Application instructions-25

X01001 DIF0 Dist WR0000, WX0000 LD X00001 and DIF0

Control instructions-1

Normal scan end

714

Instruction for use

101

Special internal output Error code Error description

102

Control instructions-4

Conditional jump

CU, CT

Code number To 255 Decimal Jump condition

104

Syntax of JMP, Cjmp

Nesting of JMP instructions is allowed

Control instructions-5

Label

LBL n

WRF001 H0001 Duplicate definition of LBL

Control instructions-6

Code number To 49 Decimal

For the instruction instruction, see Next n

106

107

Control instructions-7

Next

Syntax of for to Next

108

109

Control instructions-9

Start subroutine program

SB n

WRF001 H0004 Duplicate definition of SB H0013 SB undefined

111

RTS DER ERR

RTS

Control instructions-11

Start interrupt scan program Interrupt

To 2 , 16 to 19

To 27 Decimal

113

Control instructions-12

End interrupt scan program Return Interrupt

114

Syntax of SB n, RTS, INT n and RTI

Nesting of subroutines is allowed up to 5 levels

Usable I/O Others

Baud rate Value

+A Data length Byte +B H80 †† ††=Start code

+C H0000

118

Sample program

R7E3

WR0

DIF0

TRNS/RECV command return code table

Name Description Countermeasure

064

Transfer command-2

Recv 0 d, s, t

122

123

General purpose port switching

FUN instructions-1

Argument

124

FUN instructions-2

Refresh All points

432

Argument dummy

FUN instructions-3

Refresh Input/output

244

Input type

127

128

FUN instructions-5

High-speed Counter Operation Control

147

Argument Counter Number, operation Control value

FUN instructions-6

High-speed Counter Coincidence Output Control

138

Argument Counter Number, output Instruction

131

High-speed Counter Current Value Replacement

Argument counter Number Replacement value Storage area

FUN instructions-8

Rewrite the count value of the counter No to

FUN instructions-9

High-speed counter current value reading

132

Argument counter Number Current value storage Area

134

High-speed counter preset

FUN instructions-11

162

135

136

137

138

FUN instructions-13

173

139

FUN instructions-14

Pulse output control

149

Argument Pulse output Number

Pulse frequency output setting changes

FUN instructions-15

217

141

142

FUN instructions-16

Pulse output with acceleration/deceleration

919

143

144

145

146

Usable I/O classifications and point types

I/O Assignment

Type Assignment Point

Shows a diagram outlining this series of operations

External I/O Numbers

List of external I/O classification and data type

Classification Data type Remarks

List of I/O number conventions for external I/O

Data type Numbering convention Example

Internal Output Numbers

WR0

DR0

WM0

Lists the programming specifications for the MICRO-EH

Memory Size and Memory Assignment

Sram

Flash

Programming Devices

Following methods are used to create the user programs

System configuration using a personal computer

Programming Methods

Ladder Editor

WVCB02H WPCB02H

Out-line of opera-ting procedure Situation Point

List of procedures for creating a program

Modify Test operation, adjustment

On-line On-direct

Size of one circuit

Example when using loop symbols

Example when using a processing box

Program Transfer

WRF01A

WRF03C

WRF03D

WRF06B

Input/Output Function

Initial Setting for Special Input/Output Function

Change individual setting Store the settings in the memory

Operation Mode

Operation mode list

Input/Output Setting

Special internal output for setting detailed function

Y100 Group „ Mode setting Y101 Y102 Group 2 Group

„ In/output setting

„ Outline

„ Example

Pulse / PWM Output adjustment

Special Output Operation in CPU Stop Status

R7FC toR7FF

Counter output

Basic operation

High-Speed Counter Single-Phase

Operation of Single-Phase Counter

Preload input operation

Current value clear instruction operation

Setting of Single-Phase Counter

At abnormal setting

Individual counter setting

WRF058 Counter

WRF059 Counter

Phase counting mode

High-Speed Counter Two-Phase Counter

Operation of Two-Phase Counters

High ↓ Falling edge

↓ Falling edge Low ↑ Rising edge High

↓ Falling edge High

↑ Rising edge Low

High ↓ Falling edge Low

↑ Rising edge High

Setting of Two-Phase Counter

Diagnostic error

WRF072

WRF076

WRF058 Two-phase counter

Bit Description

PWM Output

Operation of PWM Output

Setting the PWM output on-duty value

Setting the PWM Output

Setting the PWM output frequency

Setting abnormality

Individual PWM output setting

WRF058 PWM output

WRF059 PWM output WRF05A PWM output

Pulse Train Output

Operation of Pulse Output

Setting of Pulse Output

Setting the pulse output frequency

Setting the number of output pulses

Number of output pulses for pulse output

WRF059 Pulse output

Individual setting of pulse outputs

WRF058 Pulse output

Interrupt Input

Digital Filter

Interrupt input correspondence table Terminal INT No

Input sampling number

Potentiometers

Analogue Input

Analogue Output

Sw6 Conversion mode Remarks

Analogue Expansion unit

Sw1 Sw2 Range Remarks

Sw3 Sw4 Range Remarks

Switch Stop or

Specification. a 10-point type CPU becomes

RUN mode when the RUN input is On

Input on

RUN Start

Program classification Description Expression

Normal Scan

Definition and operation

RTI RTI INT0INT0

Causes of congestion errors at normal scan

Scan time Congestion check time

10 Congestion error at periodical scan 10 ms

Periodical Scan

Stop

Continuation of operation after a congestion error

Interrupt Scan

Scan Program execution Interrupt contact on

Interrupt contact on Congestion check time

List of interrupt label Interrupt label Cause of startup

Relationship of Each Scan Type

INT16 INT17 INT18 INT27

CPU Halt time

Online Change in RUN

Conditions for performing program change while running

Instantaneous Power Failure

Powering on

Instantaneous power failure actions

RUN OFF

Function Description When to use the function

Operation Parameter

Forced Output

Forced Set/Reset

Test Operation

Installation

Installation location and environment

Installing the unit

Mounting to a DIN rail

10-2

10-3

Wiring

Separation of the power system

10-4

Wiring to the power module

Unit Screw Clamping

Wiring to the input terminals DC input AC input

10-5

Wiring to the output terminals Relay output

Transistor output

EH-*XXDT

Transistor output Source type

Life characteristics 125 V AC

10-7

Wiring to the unit terminals

10-8

Communication port specification

Port function

Port

Ascii

11-2

Off H8000 Transmission procedure 4800 bps

Remarks

Port 2 specifications

Setting port

Bit WRF03D Initial value

11-3

General purpose port Port 1,2

1n station communication on RS-485

Port 2 hardware

11-4

Modem Control Function

Configuration

AT Commands

List of commands extract

Command Function overview Example

Register Set value Function

Number format Word format

Sequence

11-7

Connecting to the Ports

Port

Case of RS-422

Connection for 1n station communication by RS-485 11-9

11-10

Error Codes

Error Error name Classifi

Code Detection timing Cation

R7CF

Failure detection

Syntax and Assembler Error Codes

LBL

For

INT

Operation Error Codes

CAL

JMP

Cjmp

Name Meaning Description Setting Resetting Condition

Bit Special Internal Output Area

R7CB

R7CE

12-6

12-7

List of special internal outputs that can be stored

Special internal output Function That can be stored

WRF07B

WRF07C WRF07D WRF07E

Setting Resetting Condition

12.5

Name Storage data

12-9

Name Storage data Description Setting

12-10

12-11

PI/O function Individual setting Request

Name Stored data Description

Name Stored data Description Setting Resetting

12-12

Ladder Editor

Error Display and Actions

13-1

13-2

13-3

Process flow when an error occurred is shown below

Error code Error name Corrective action

13-4

Checklist when Abnormality Occurred

13-5

13-6

Procedures to Solve Abnormality

CPU LED, I/O LED

Power supply check

13-7

13-8

13-9

13-10

13-11

Assignment error is generated, but data is read

Data cannot be entered

13-12

13-13

13-14

CPU operates, but output signals are not detected

Assignment error occurred, but output is normal

13-15

13-16

Operation verification procedures

Peripheral unit name Form

Detailed operation example

14-1

E P 1 Starting the Ladder Editor for Windows

14-2

Select H-302 for the CPU type setting

E P 2 Initialization

Menu bar

14-3

Assign in the Menu bar

14-4

Setting from the I/O Assign List

14-5

Setting from the Slot Setting Status

14-6

14-7

E P 3 Program Input

Click the OK button. The dialogue closes

Click the OK button in the Processing Box

14-8

14-9

Input I/O No., time base, and the first setting value

M, Y, TD, SS, WDT, MS, TMR, CU, RCU, CTU, CTD, CL

14-10

Input comparison expression and comment Click the OK button

Click the circuit write icon Tool bar

E P 4 Checking Program Errors

14-11

E P 5 Saving the Program

14-12

E P 6 Program Transfer to CPU

14-13

Click File → CPU write in the Menu bar

14-14

14-15

E P 7 Monitoring Verifying the Operation

I/O Monitor dialogue box is displayed

Click the icon in the Symbol bar

I/O monitor can be specified in the following two ways

Monitor and display 16 points from Y100

14-16

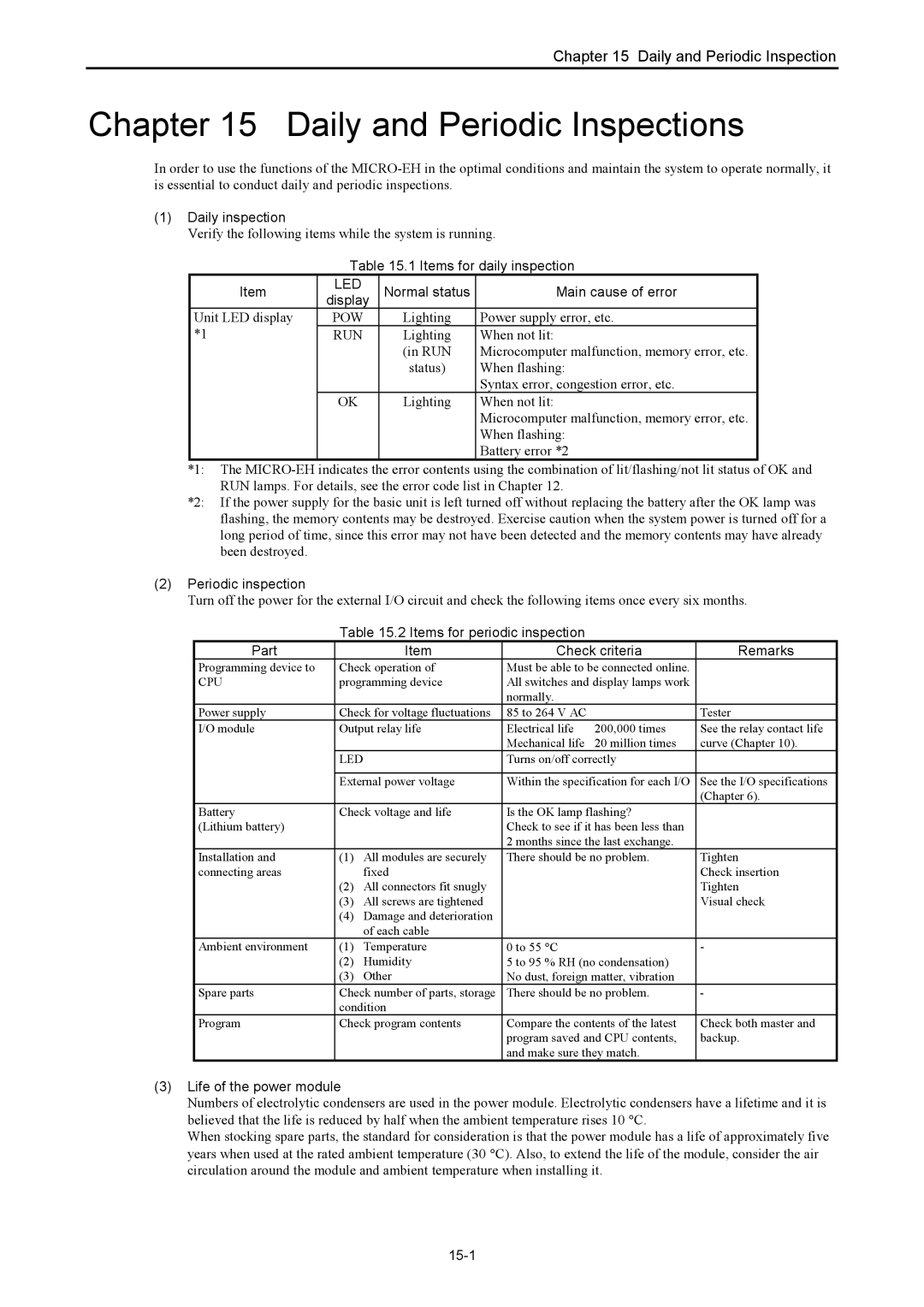

Normal status Main cause of error

Life of the power module

Daily inspection

Items for daily inspection

15-2

Life of the battery

How to replace the battery

LDI

ANI

ORI

Not

EH-150 200 250 252 2000 2002 4010 700 1002 300 702 302

Arithmetic instructions Instruction Instruction name

Application instructions 2/2 Instruction Instruction name

Free

FUN instructions 1/5 Instruction Instruction name

FUN instructions 2/5 Instruction Instruction name

FUN instructions 3/5 Instruction Instruction name

FUN instructions 4/5 Instruction Instruction name

FUN instructions 5/5 Instruction Instruction name

Appendix 2 Standards

Standards