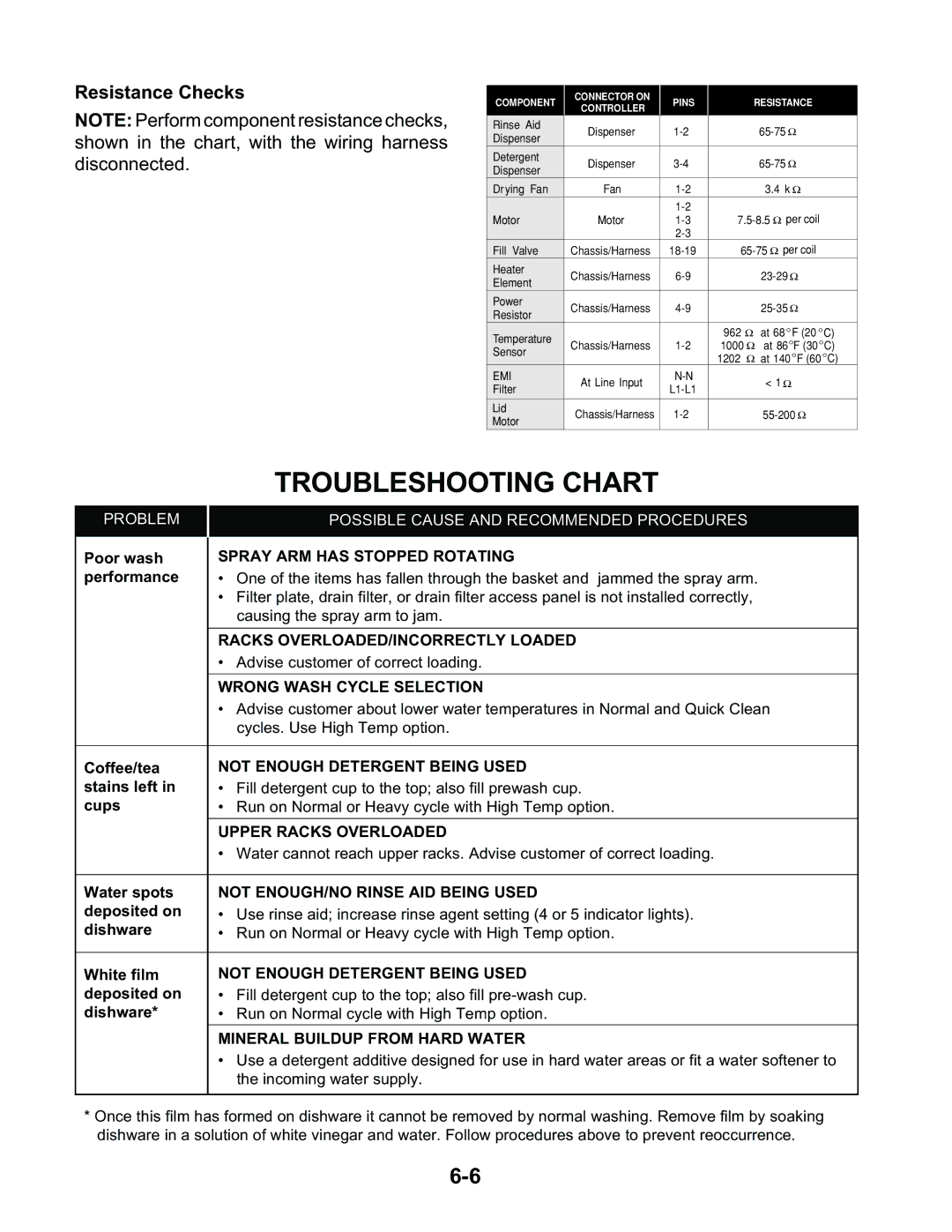

Resistance Checks

NOTE: Perform component resistance checks, shown in the chart, with the wiring harness disconnected.

COMPONENT | CONNECTOR ON | PINS |

| RESISTANCE |

|

| |

|

|

| |||||

CONTROLLER |

|

|

| ||||

|

|

|

|

|

|

| |

Rinse Aid | Dispenser |

|

|

|

| ||

Dispenser |

|

|

|

| |||

|

|

|

|

|

|

| |

Detergent | Dispenser |

|

|

|

| ||

Dispenser |

|

|

|

| |||

|

|

|

|

|

|

| |

Drying Fan | Fan |

|

| 3.4 k Ω |

|

| |

|

|

| |||||

Motor | Motor |

| |||||

|

|

|

|

|

|

| |

Fill Valve | Chassis/Harness |

|

| ||||

Heater | Chassis/Harness |

|

|

|

| ||

Element |

|

|

|

| |||

|

|

|

|

|

|

| |

Power | Chassis/Harness |

|

|

|

| ||

Resistor |

|

|

|

| |||

|

|

|

|

|

|

| |

Temperature |

|

| 962 Ω at 68 °F (20 °C) | ||||

Chassis/Harness | 1000 | Ω | ° | ° | C) | ||

Sensor |

| at 86 F (30 |

| ||||

|

| 1202 Ω at 140°F (60°C) | |||||

|

|

| |||||

EMI | At Line Input |

|

| < 1 Ω |

|

| |

Filter |

|

|

|

| |||

|

|

|

|

|

| ||

Lid | Chassis/Harness |

|

|

|

| ||

Motor |

|

|

|

| |||

|

|

|

|

|

|

| |

TROUBLESHOOTING CHART

PROBLEM

POSSIBLE CAUSE AND RECOMMENDED PROCEDURES

Poor wash | SPRAY ARM HAS STOPPED ROTATING | |

performance | • | One of the items has fallen through the basket and jammed the spray arm. |

| • | Filter plate, drain filter, or drain filter access panel is not installed correctly, |

|

| causing the spray arm to jam. |

| RACKS OVERLOADED/INCORRECTLY LOADED |

| • Advise customer of correct loading. |

|

|

| WRONG WASH CYCLE SELECTION |

| • Advise customer about lower water temperatures in Normal and Quick Clean |

| cycles. Use High Temp option. |

|

|

Coffee/tea | NOT ENOUGH DETERGENT BEING USED |

stains left in | • Fill detergent cup to the top; also fill prewash cup. |

cups | • Run on Normal or Heavy cycle with High Temp option. |

|

|

| UPPER RACKS OVERLOADED |

| • Water cannot reach upper racks. Advise customer of correct loading. |

|

|

Water spots | NOT ENOUGH/NO RINSE AID BEING USED |

deposited on | • Use rinse aid; increase rinse agent setting (4 or 5 indicator lights). |

dishware | • Run on Normal or Heavy cycle with High Temp option. |

|

|

White film | NOT ENOUGH DETERGENT BEING USED |

deposited on | • Fill detergent cup to the top; also fill |

dishware* | • Run on Normal cycle with High Temp option. |

|

|

| MINERAL BUILDUP FROM HARD WATER |

| • Use a detergent additive designed for use in hard water areas or fit a water softener to |

| the incoming water supply. |

*Once this film has formed on dishware it cannot be removed by normal washing. Remove film by soaking dishware in a solution of white vinegar and water. Follow procedures above to prevent reoccurrence.