KODAK 1200i WIDE-FORMAT PRINTING SYSTEM

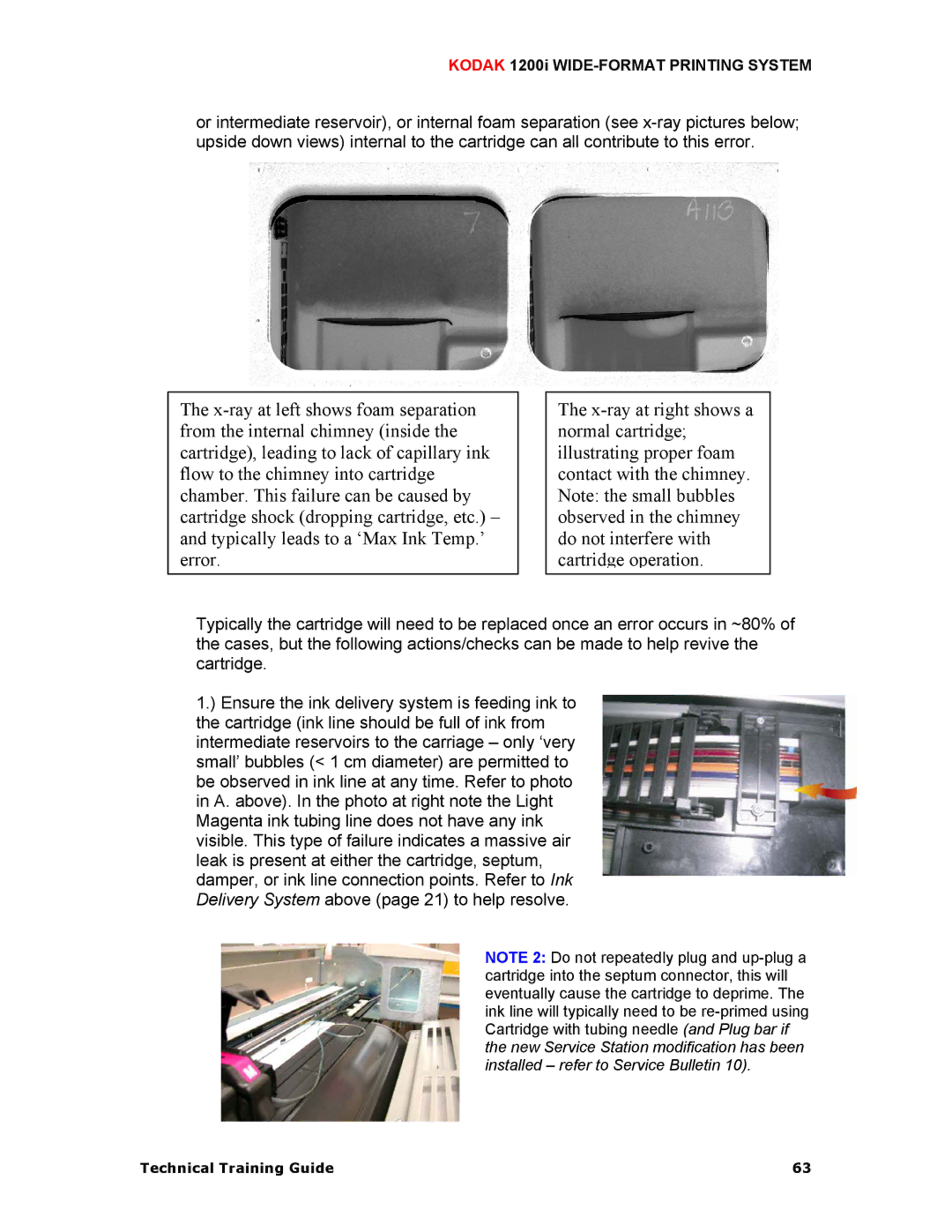

or intermediate reservoir), or internal foam separation (see

The

The

Typically the cartridge will need to be replaced once an error occurs in ~80% of the cases, but the following actions/checks can be made to help revive the cartridge.

1.) Ensure the ink delivery system is feeding ink to the cartridge (ink line should be full of ink from intermediate reservoirs to the carriage – only ‘very small’ bubbles (< 1 cm diameter) are permitted to be observed in ink line at any time. Refer to photo in A. above). In the photo at right note the Light Magenta ink tubing line does not have any ink visible. This type of failure indicates a massive air leak is present at either the cartridge, septum, damper, or ink line connection points. Refer to Ink Delivery System above (page 21) to help resolve.

NOTE 2: Do not repeatedly plug and

Technical Training Guide | 63 |