Maintenance

17.0 MAINTENANCE

! WARNING

Only qualified service personnel should perform maintenance on the static switch. Lethal voltages exist inside the unit during normal operation.

The unit is supplied by multiple AC power sources. Disconnect and

Minimal periodic maintenance of the Liebert STS2 is required. As with all electrical distribution components, the system should be regularly inspected for electrical connection integrity, signs of excessive temperatures, dirt accumulation, and proper system operation.

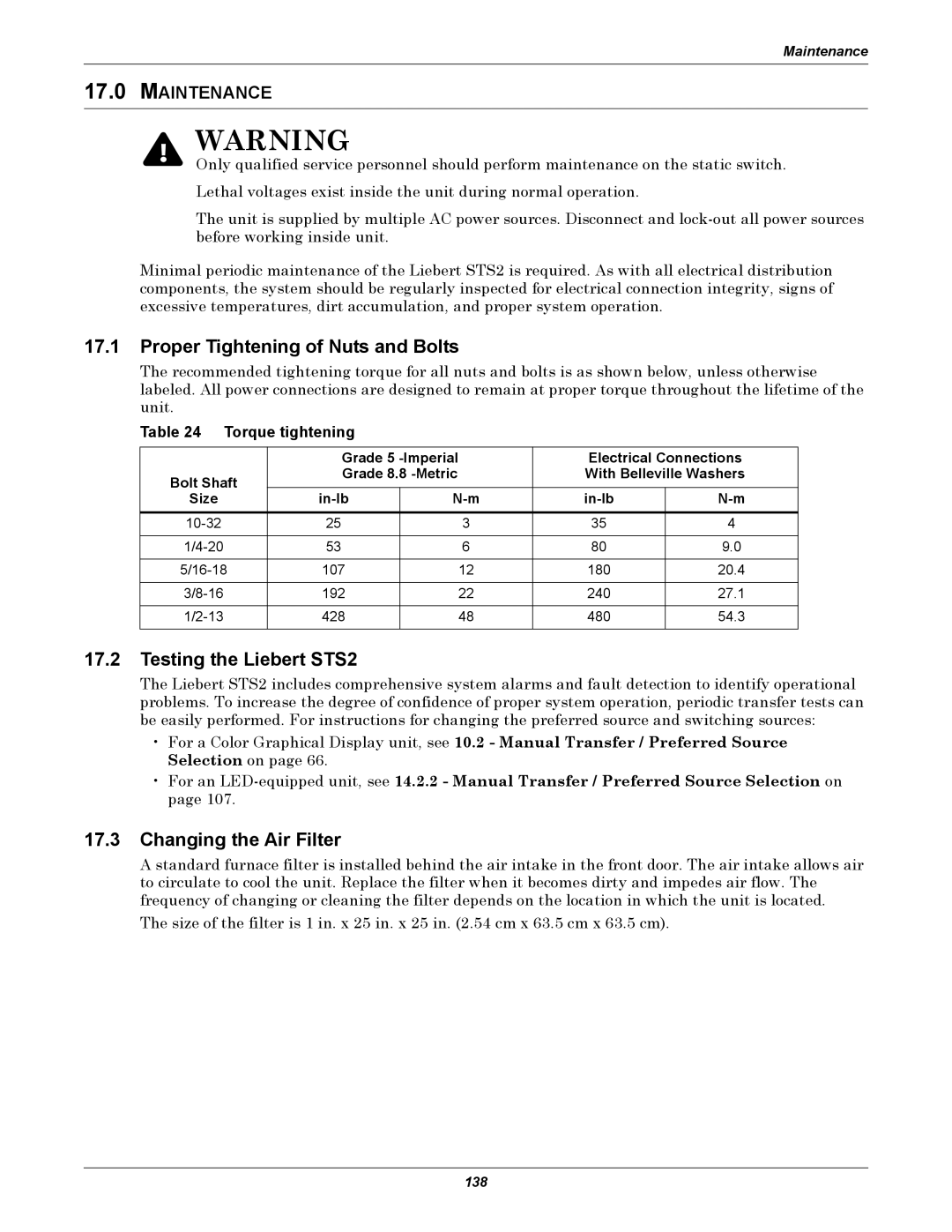

17.1Proper Tightening of Nuts and Bolts

The recommended tightening torque for all nuts and bolts is as shown below, unless otherwise labeled. All power connections are designed to remain at proper torque throughout the lifetime of the unit.

Table 24 Torque tightening

| Grade 5 | Electrical Connections | ||

Bolt Shaft | Grade 8.8 | With Belleville Washers | ||

|

|

|

| |

Size | ||||

|

|

|

|

|

25 | 3 | 35 | 4 | |

|

|

|

|

|

53 | 6 | 80 | 9.0 | |

|

|

|

|

|

107 | 12 | 180 | 20.4 | |

|

|

|

|

|

192 | 22 | 240 | 27.1 | |

|

|

|

|

|

428 | 48 | 480 | 54.3 | |

|

|

|

|

|

17.2Testing the Liebert STS2

The Liebert STS2 includes comprehensive system alarms and fault detection to identify operational problems. To increase the degree of confidence of proper system operation, periodic transfer tests can be easily performed. For instructions for changing the preferred source and switching sources:

•For a Color Graphical Display unit, see 10.2 - Manual Transfer / Preferred Source Selection on page 66.

•For an

17.3Changing the Air Filter

A standard furnace filter is installed behind the air intake in the front door. The air intake allows air to circulate to cool the unit. Replace the filter when it becomes dirty and impedes air flow. The frequency of changing or cleaning the filter depends on the location in which the unit is located.

The size of the filter is 1 in. x 25 in. x 25 in. (2.54 cm x 63.5 cm x 63.5 cm).

138