OPERATION | ||

|

|

|

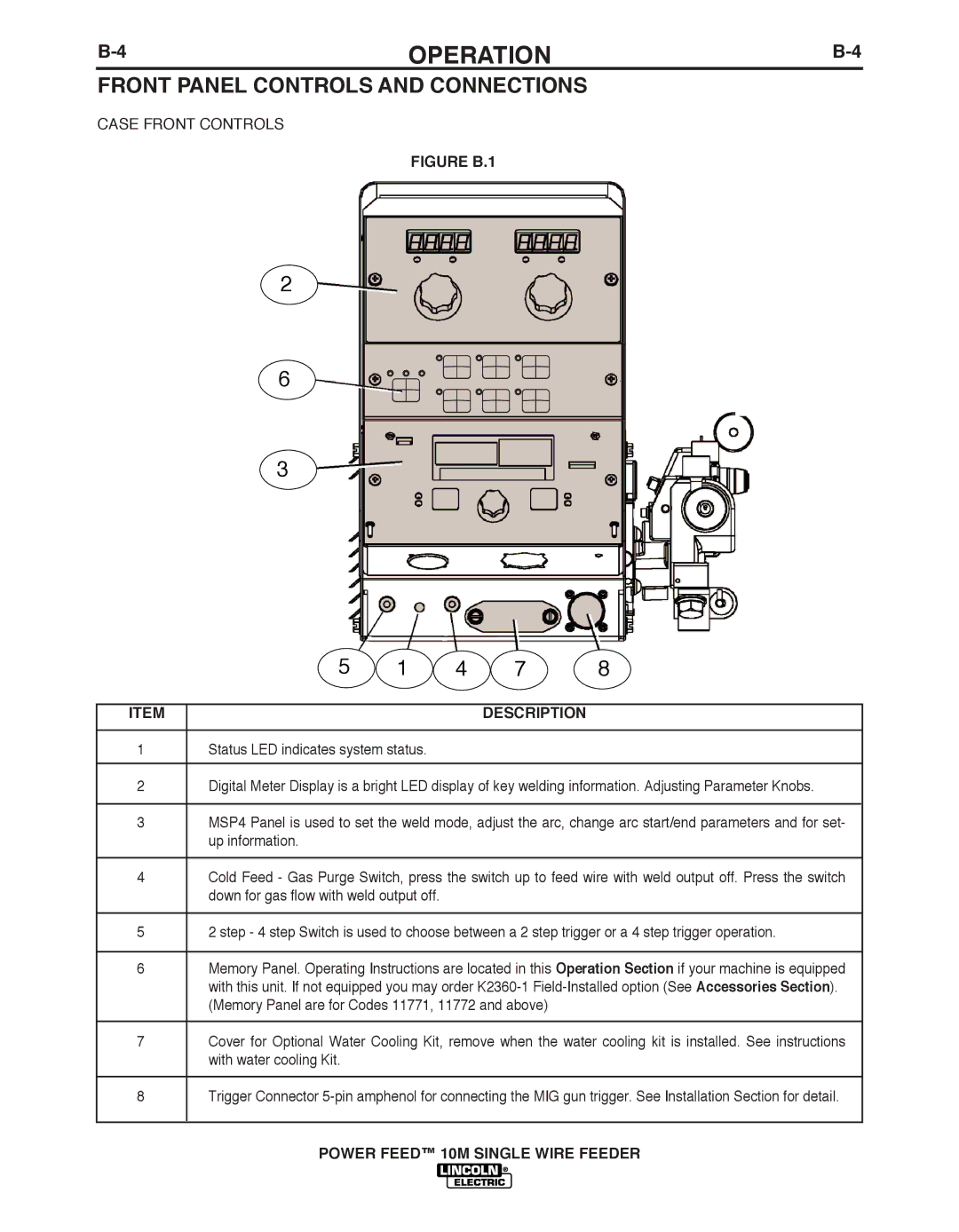

FRONT PANEL CONTROLS AND CONNECTIONS

CASE FRONT CONTROLS

FIGURE b.1

2

6

3

| 5 | 1 | 4 | 7 | 8 |

|

|

|

|

|

|

ITEM |

|

|

| DESCRIPTION |

|

|

|

|

|

| |

1 | Status LED indicates system status. |

|

|

| |

|

| ||||

2 | Digital Meter Display is a bright LED display of key welding information. Adjusting Parameter Knobs. | ||||

|

| ||||

3 | MSP4 Panel is used to set the weld mode, adjust the arc, change arc start/end parameters and for set- | ||||

| up information. |

|

|

|

|

|

| ||||

4 | Cold Feed - Gas Purge Switch, press the switch up to feed wire with weld output off. Press the switch | ||||

| down for gas flow with weld output off. |

|

|

| |

|

| ||||

5 | 2 step - 4 step Switch is used to choose between a 2 step trigger or a 4 step trigger operation. | ||||

|

| ||||

6 | Memory Panel. Operating Instructions are located in this Operation Section if your machine is equipped | ||||

| with this unit. If not equipped you may order | ||||

| (Memory Panel are for Codes 11771, 11772 and above) |

| |||

|

| ||||

7 | Cover for Optional Water Cooling Kit, remove when the water cooling kit is installed. See instructions | ||||

| with water cooling Kit. |

|

|

|

|

|

| ||||

8 | Trigger Connector | ||||

|

|

|

|

|

|