|

| TROUbLESHOOTING |

| ||

|

|

|

|

|

|

|

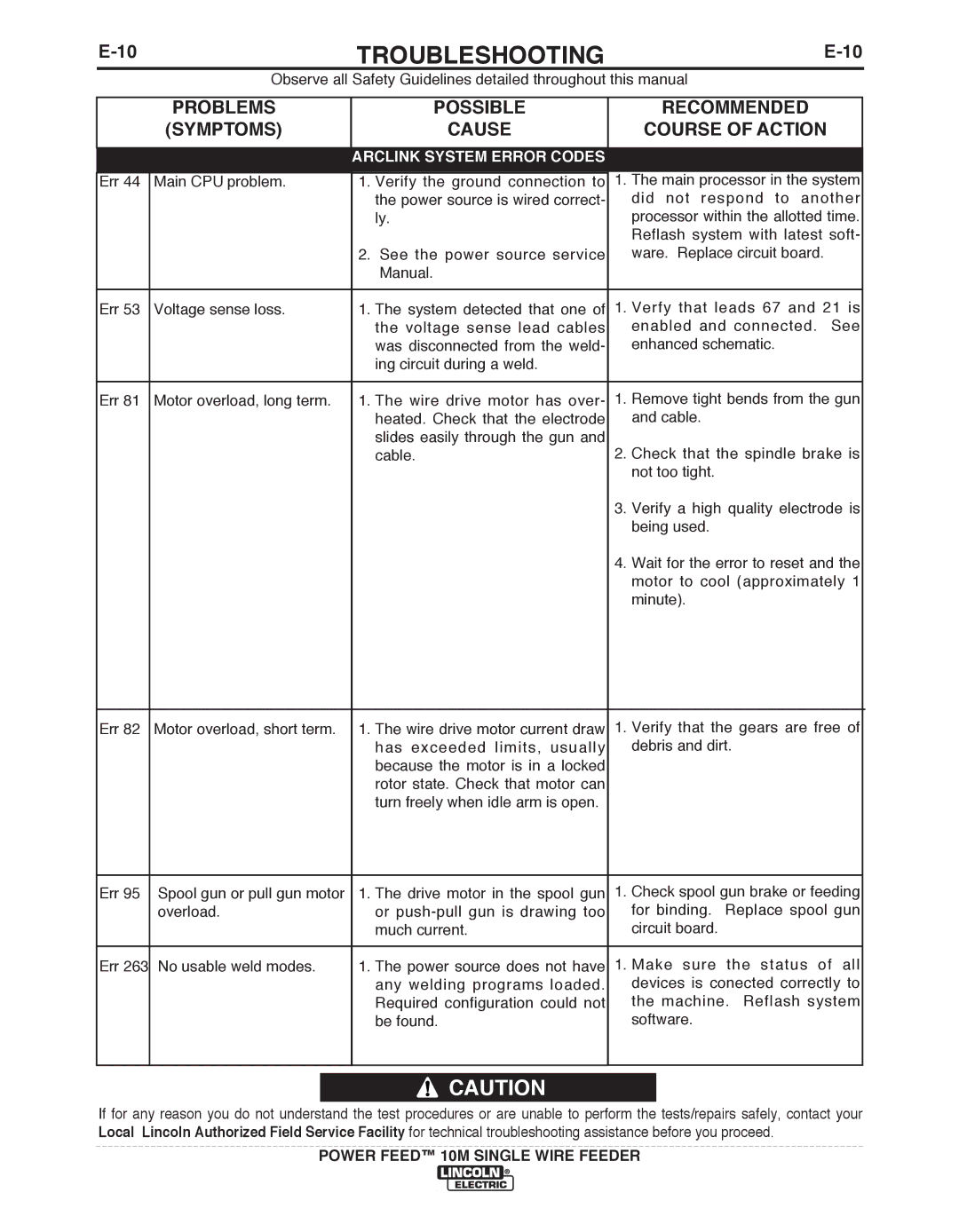

| Observe all Safety Guidelines detailed throughout this manual | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| PRObLEMS | POSSIbLE |

| RECOMMENDED |

|

| (SYMPTOMS) | CAUSE |

| COURSE OF ACTION |

|

|

|

|

|

|

|

|

| ARCLINK SYSTEM ERROR CODES |

|

|

|

|

|

|

| |

Err 44 | Main CPU problem. | 1. Verify the ground connection to | 1. | The main processor in the system | |

|

|

| the power source is wired correct- |

| did not respond to another |

|

|

| ly. |

| processor within the allotted time. |

|

|

|

|

| Reflash system with latest soft- |

|

|

| 2. See the power source service |

| ware. Replace circuit board. |

|

|

| Manual. |

|

|

|

|

|

|

| |

Err 53 | Voltage sense loss. | 1. The system detected that one of | 1. | Verfy that leads 67 and 21 is | |

|

|

| the voltage sense lead cables |

| enabled and connected. See |

|

|

| was disconnected from the weld- |

| enhanced schematic. |

|

|

| ing circuit during a weld. |

|

|

|

|

|

|

| |

Err 81 | Motor overload, long term. | 1. The wire drive motor has over- | 1. | Remove tight bends from the gun | |

|

|

| heated. Check that the electrode |

| and cable. |

|

|

| slides easily through the gun and |

|

|

|

|

| cable. | 2. | Check that the spindle brake is |

|

|

|

|

| not too tight. |

|

|

|

| 3. | Verify a high quality electrode is |

|

|

|

|

| being used. |

|

|

|

| 4. | Wait for the error to reset and the |

|

|

|

|

| motor to cool (approximately 1 |

|

|

|

|

| minute). |

|

|

|

|

| |

Err 82 | Motor overload, short term. | 1. The wire drive motor current draw | 1. | Verify that the gears are free of | |

|

|

| has exceeded limits, usually |

| debris and dirt. |

|

|

| because the motor is in a locked |

|

|

|

|

| rotor state. Check that motor can |

|

|

|

|

| turn freely when idle arm is open. |

|

|

|

|

|

|

| |

Err 95 | Spool gun or pull gun motor | 1. The drive motor in the spool gun | 1. | Check spool gun brake or feeding | |

|

| overload. | or |

| for binding. Replace spool gun |

|

|

| much current. |

| circuit board. |

|

|

|

|

| |

Err 263 | No usable weld modes. | 1. The power source does not have | 1. | Make sure the status of all | |

|

|

| any welding programs loaded. |

| devices is conected correctly to |

|

|

| Required configuration could not |

| the machine. Reflash system |

|

|

| be found. |

| software. |

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.