| OPERATION | ||||

|

|

|

|

|

|

|

|

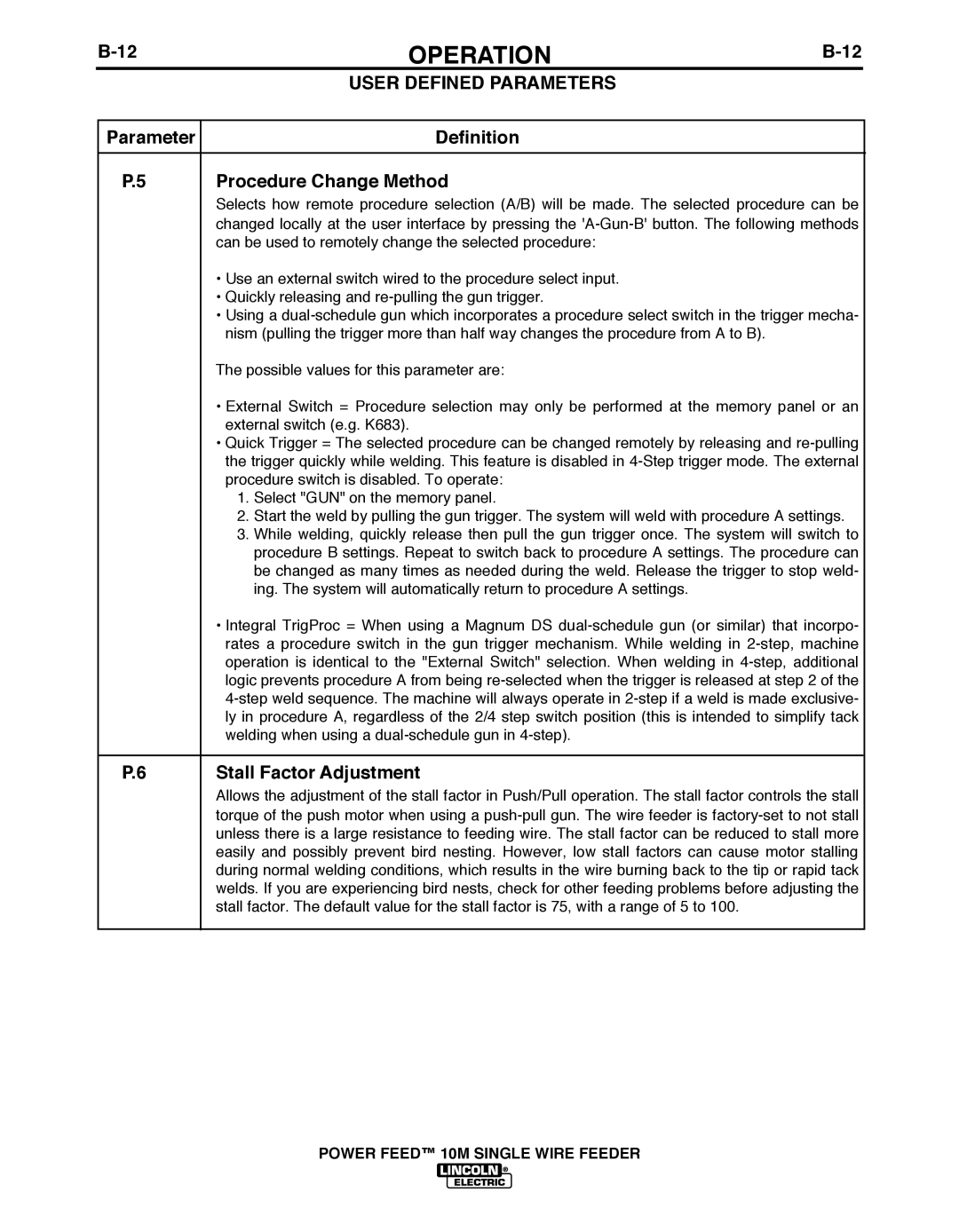

| USER DEFINED PARAMETERS |

|

|

|

|

|

|

| |

|

|

|

|

| |

| Parameter | Definition |

|

| |

|

|

|

|

| |

| P.5 | Procedure Change Method |

|

| |

|

|

| Selects how remote procedure selection (A/B) will be made. The selected procedure can be |

| |

|

|

| changed locally at the user interface by pressing the |

| |

|

|

| can be used to remotely change the selected procedure: |

|

|

|

|

| • Use an external switch wired to the procedure select input. |

|

|

|

|

| • Quickly releasing and |

|

|

|

|

| • Using a |

| |

|

|

| nism (pulling the trigger more than half way changes the procedure from A to B). |

|

|

|

|

| The possible values for this parameter are: |

|

|

|

|

| • External Switch = Procedure selection may only be performed at the memory panel or an |

| |

|

|

| external switch (e.g. K683). |

|

|

|

|

| • Quick Trigger = The selected procedure can be changed remotely by releasing and |

| |

|

|

| the trigger quickly while welding. This feature is disabled in |

| |

|

|

| procedure switch is disabled. To operate: |

|

|

|

|

| 1. Select "GUN" on the memory panel. |

|

|

|

|

| 2. Start the weld by pulling the gun trigger. The system will weld with procedure A settings. |

| |

|

|

| 3. While welding, quickly release then pull the gun trigger once. The system will switch to |

| |

|

|

| procedure B settings. Repeat to switch back to procedure A settings. The procedure can |

| |

|

|

| be changed as many times as needed during the weld. Release the trigger to stop weld- |

| |

|

|

| ing. The system will automatically return to procedure A settings. |

|

|

|

|

| • Integral TrigProc = When using a Magnum DS |

| |

|

|

| rates a procedure switch in the gun trigger mechanism. While welding in |

| |

|

|

| operation is identical to the "External Switch" selection. When welding in |

| |

|

|

| logic prevents procedure A from being |

| |

|

|

|

| ||

|

|

| ly in procedure A, regardless of the 2/4 step switch position (this is intended to simplify tack |

| |

|

|

| welding when using a |

|

|

|

|

|

|

| |

| P.6 | Stall Factor Adjustment |

|

| |

|

|

| Allows the adjustment of the stall factor in Push/Pull operation. The stall factor controls the stall |

| |

|

|

| torque of the push motor when using a |

| |

|

|

| unless there is a large resistance to feeding wire. The stall factor can be reduced to stall more |

| |

|

|

| easily and possibly prevent bird nesting. However, low stall factors can cause motor stalling |

| |

|

|

| during normal welding conditions, which results in the wire burning back to the tip or rapid tack |

| |

|

|

| welds. If you are experiencing bird nests, check for other feeding problems before adjusting the |

| |

|

|

| stall factor. The default value for the stall factor is 75, with a range of 5 to 100. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|