Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

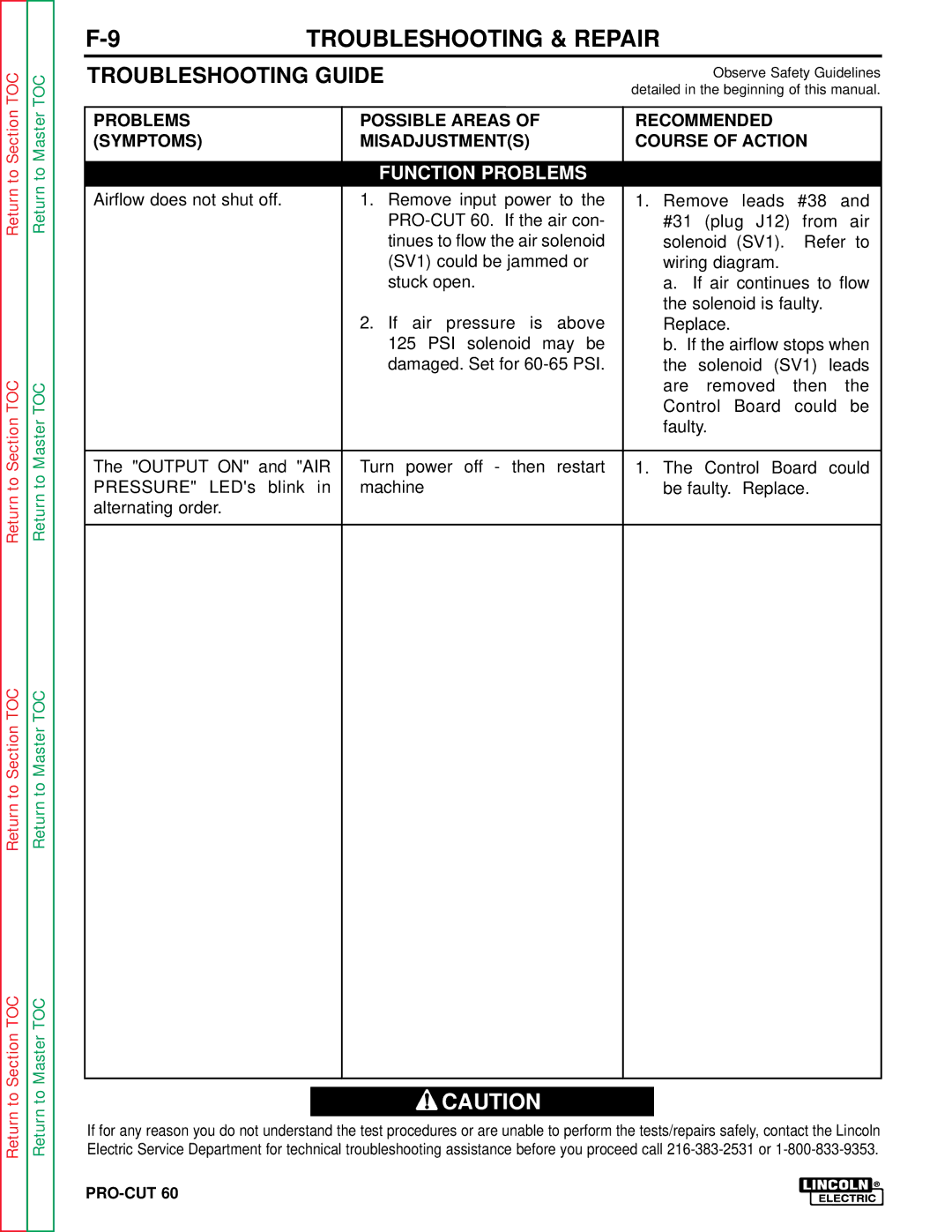

TROUBLESHOOTING & REPAIR |

|

|

| |||

TROUBLESHOOTING GUIDE |

| Observe Safety Guidelines | ||||

|

|

| detailed in the beginning of this manual. | |||

|

|

|

|

|

| |

PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED |

|

| |

(SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION |

| ||

|

|

|

|

|

|

|

|

| FUNCTION PROBLEMS |

|

|

|

|

Airflow does not shut off. | 1. Remove input power to the | 1. Remove leads #38 and | ||||

|

| #31 (plug J12) from air | ||||

|

| tinues to flow the air solenoid | solenoid (SV1). | Refer to | ||

|

| (SV1) could be jammed or | wiring diagram. |

|

| |

|

| stuck open. | a. If air continues to flow | |||

|

| 2. If air pressure is above | the solenoid is faulty. |

| ||

|

| Replace. |

|

| ||

|

| 125 PSI solenoid may be | b. If the airflow stops when | |||

|

| damaged. Set for | the | solenoid (SV1) leads | ||

|

|

| are | removed | then | the |

|

|

| Control Board | could | be | |

|

|

| faulty. |

|

| |

|

|

| ||||

The "OUTPUT ON" and "AIR | Turn power off - then restart | 1. The Control Board could | ||||

PRESSURE" LED's | blink in | machine | be faulty. Replace. |

| ||

alternating order. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed call