INSTALLATION |

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

3.Connect the work terminal to a ground within ten feet of the machine.

a.Use grounding cable that is the same size as, or larger than, the work cable.

b.Make grounding cable as short as possible.

c.Connect the ground tightly.

d.Use one of the following ground methods:

(1)Connect to a metal underground water pipe that is in direct contact with earth for ten feet or more.

(2)Connect to 3/4" (19mm) galvanized pipe or a 5/8" (16mm) solid galvanized iron, steel, or copper rod driven at least eight feet into the ground.

NOTE: Do Not use the building frame electri- cal conduit or a long pipe system for ground- ing the machine. This could result in increased high frequency interference.

NOTE: When the machine is used in a metal building, drive several good earth grounds around the edge of the building. Use the method in 2 above.

4.Enclose all electrical conductors within 50 feet (15.2m) of the machine in grounded rigid metallic conduit or equivalent shielding.

a.Do not use flexible metallic conduit.

5.Make work and torch leads as short and as close together as possible.

a.Lead length should not exceed 50 feet (15.2m).

b.Tape leads together when possible.

6.Check torch and work cable rubber insulation coverings to be sure they do not have any cracks or cuts that could result in high fre- quency leakage that could interfere with other electronic equipment.

a.Use insulated work cables with a high natural rubber content, such as the Lincoln

7.Keep the torch in good repair and all connec- tions tight to reduce high frequency leakage.

8.Keep all access panels and covers tightly closed.

Follow these procedures for the best operating results. Failure to follow these procedures can cause interference and machine performance problems.

INPUT ELECTRICAL

CONNECTIONS

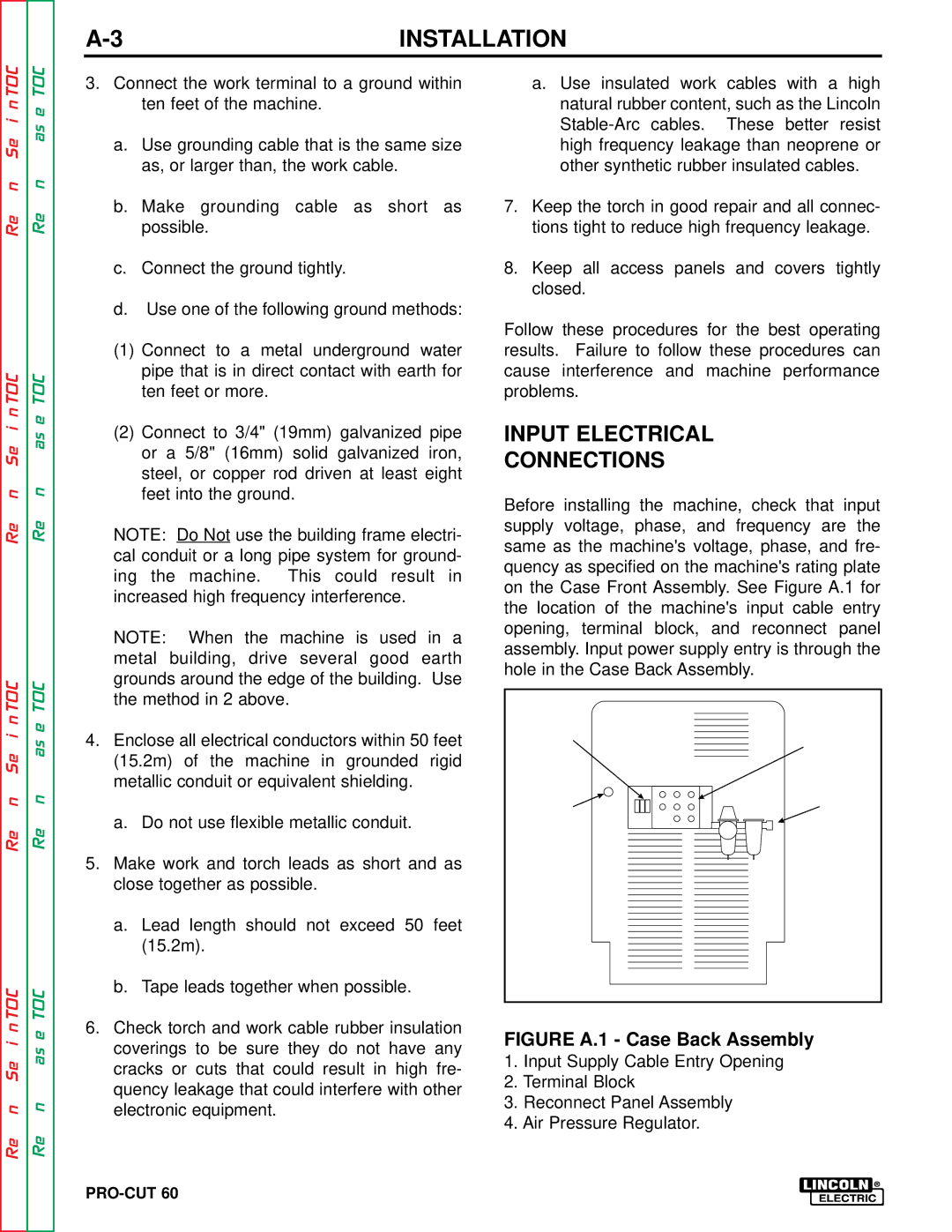

Before installing the machine, check that input supply voltage, phase, and frequency are the same as the machine's voltage, phase, and fre- quency as specified on the machine's rating plate on the Case Front Assembly. See Figure A.1 for the location of the machine's input cable entry opening, terminal block, and reconnect panel assembly. Input power supply entry is through the hole in the Case Back Assembly.

➁ ➂

➂

➀

➃

➃

FIGURE A.1 - Case Back Assembly

1.Input Supply Cable Entry Opening

2.Terminal Block

3.Reconnect Panel Assembly

4.Air Pressure Regulator.