OPERATION |

Return to Section TOC

Return to Section TOC

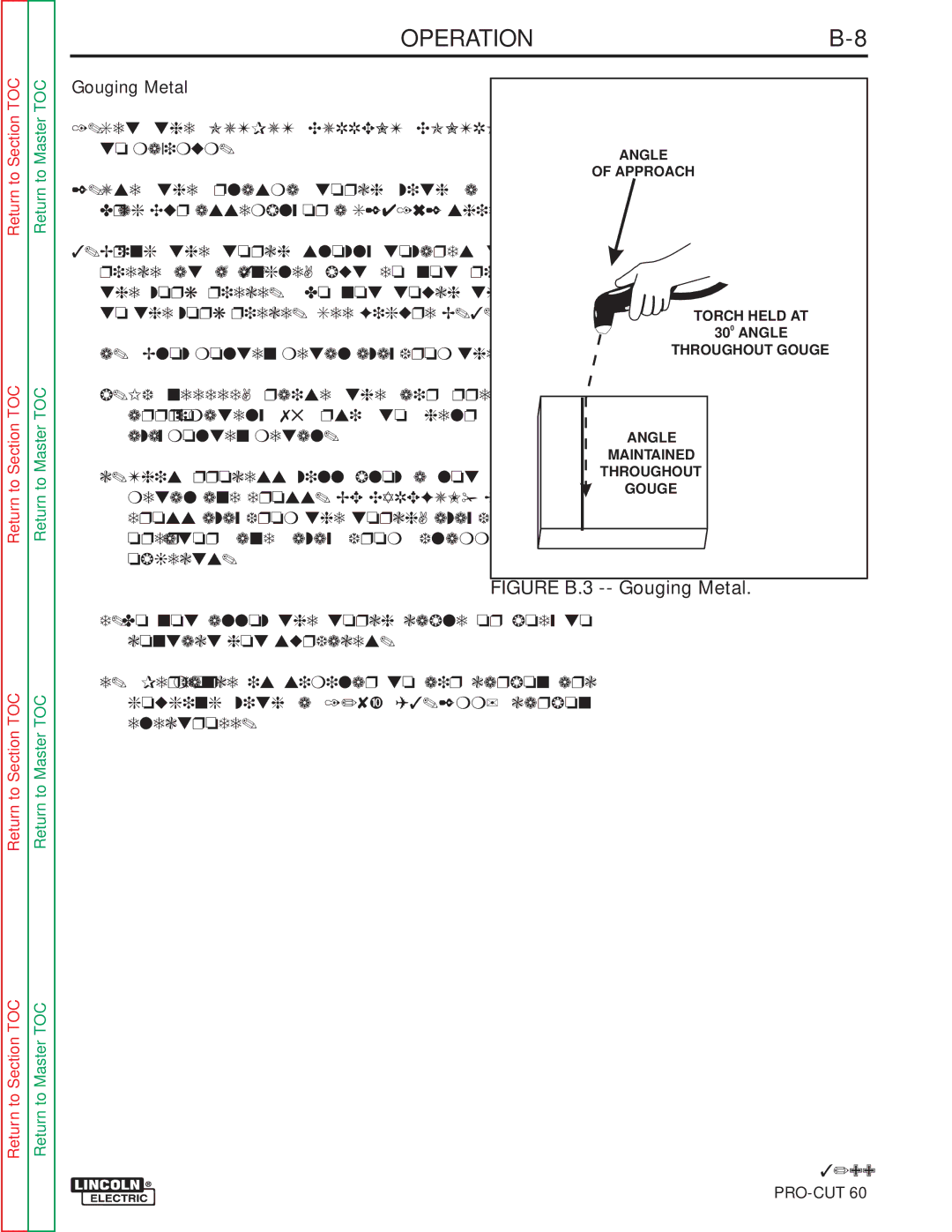

Gouging Metal

1.Set the OUTPUT CURRENT CONTROL to maximum.

2.Use the plasma torch with a S24114 Drag Cup assembly or a S24162 shield cup.

3.Bring the torch slowly towards the work piece at a 300 angle, but do not pierce the work piece. Do not touch the nozzle to the work piece. See Figure B.3.

a.Blow molten metal away from the torch.

b.If needed, raise the air pressure to approximately 75 psi to help blow away molten metal.

c.This process will blow a lot of molten metal and dross. BE CAREFUL! Blow the dross away from the torch, away from the operator and away from flammable objects.

ANGLE

OF APPROACH

TORCH HELD AT

300 ANGLE

THROUGHOUT GOUGE

ANGLE

MAINTAINED

THROUGHOUT

GOUGE

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

FIGURE B.3 -- Gouging Metal.

d. Do not allow the torch cable or body to contact hot surfaces.

e.Performance is similar to air carbon arc gouging with a 1/8” (3.2mm) carbon electrode.

3/99