Return to Master TOC

PULSE WIDTH MODULATION

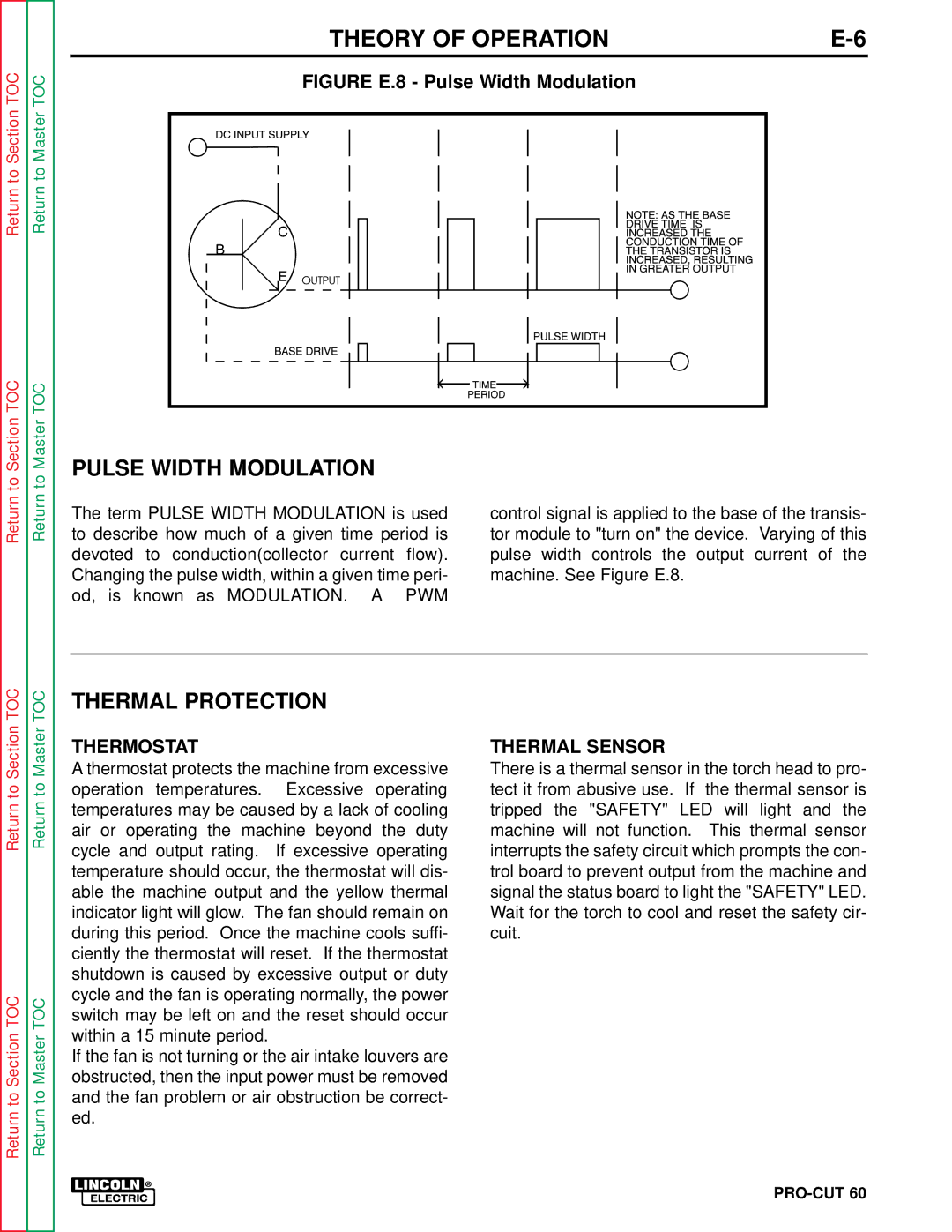

The term PULSE WIDTH MODULATION is used to describe how much of a given time period is devoted to conduction(collector current flow). Changing the pulse width, within a given time peri- od, is known as MODULATION. A PWM

control signal is applied to the base of the transis- tor module to "turn on" the device. Varying of this pulse width controls the output current of the machine. See Figure E.8.

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

THERMAL PROTECTION

THERMOSTAT

A thermostat protects the machine from excessive operation temperatures. Excessive operating temperatures may be caused by a lack of cooling air or operating the machine beyond the duty cycle and output rating. If excessive operating temperature should occur, the thermostat will dis- able the machine output and the yellow thermal indicator light will glow. The fan should remain on during this period. Once the machine cools suffi- ciently the thermostat will reset. If the thermostat shutdown is caused by excessive output or duty cycle and the fan is operating normally, the power switch may be left on and the reset should occur within a 15 minute period.

If the fan is not turning or the air intake louvers are obstructed, then the input power must be removed and the fan problem or air obstruction be correct- ed.

THERMAL SENSOR

There is a thermal sensor in the torch head to pro- tect it from abusive use. If the thermal sensor is tripped the "SAFETY" LED will light and the machine will not function. This thermal sensor interrupts the safety circuit which prompts the con- trol board to prevent output from the machine and signal the status board to light the "SAFETY" LED. Wait for the torch to cool and reset the safety cir- cuit.