Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR |

|

|

|

|

| |||||||||||

TROUBLESHOOTING GUIDE |

|

|

|

|

|

|

|

|

| Observe Safety Guidelines | ||||||

|

|

|

|

|

|

|

|

|

| detailed in the beginning of this manual. | ||||||

|

|

|

|

|

|

|

| |||||||||

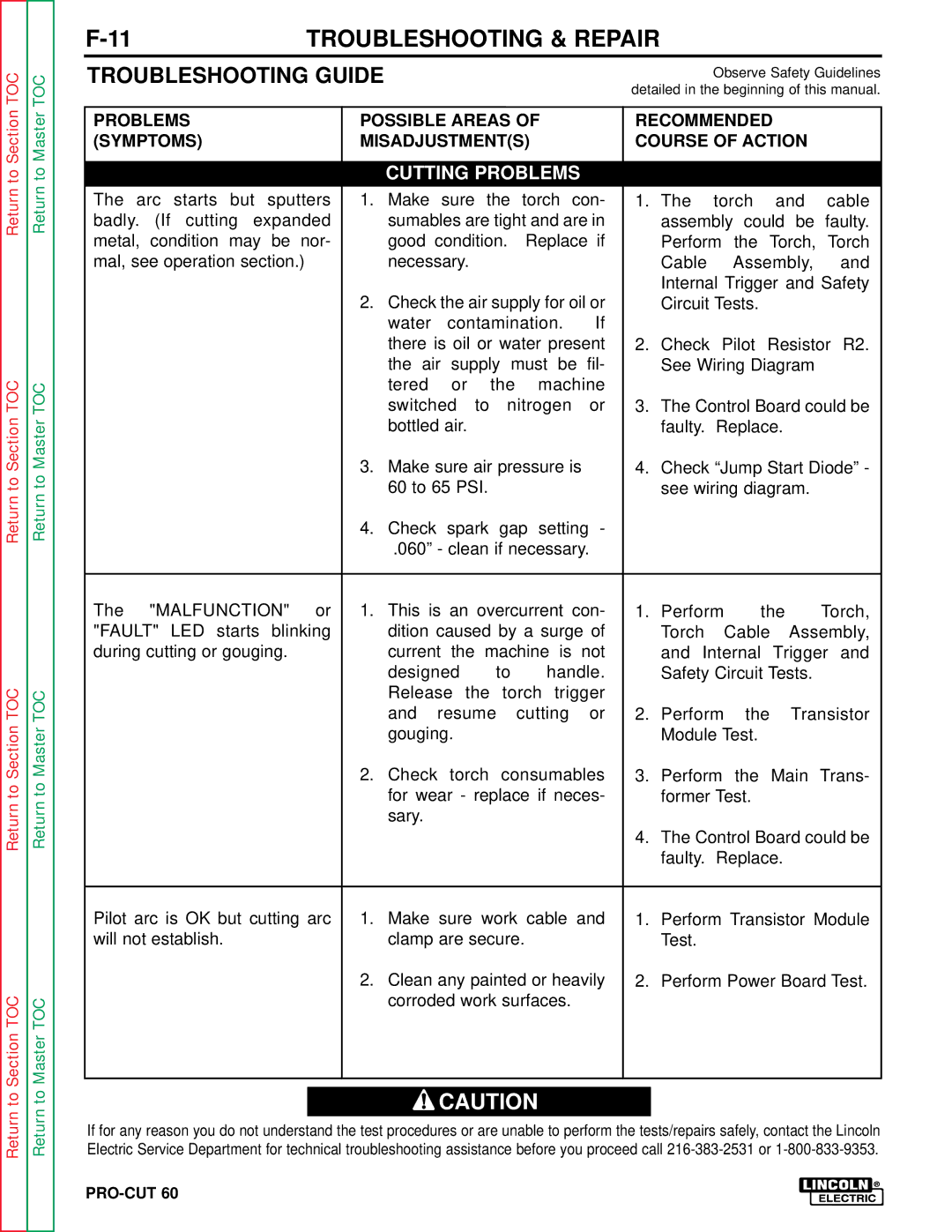

PROBLEMS | POSSIBLE AREAS OF |

| RECOMMENDED |

|

| |||||||||||

(SYMPTOMS) | MISADJUSTMENT(S) |

| COURSE OF ACTION |

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

| CUTTING PROBLEMS |

|

|

|

|

|

|

|

| ||||

The arc starts but sputters | 1. | Make sure the torch con- | 1. |

| The | torch | and | cable | ||||||||

badly. | (If cutting expanded |

| sumables are tight and are in |

|

| assembly could be | faulty. | |||||||||

metal, condition may be nor- |

| good condition. | Replace if |

|

| Perform | the Torch, | Torch | ||||||||

mal, see operation section.) |

| necessary. |

|

|

|

|

| Cable |

| Assembly, | and | |||||

|

|

| 2. | Check the air supply for oil or |

|

| Internal Trigger and Safety | |||||||||

|

|

|

|

| Circuit Tests. |

|

| |||||||||

|

|

|

| water | contamination. | If |

|

|

|

|

|

|

| |||

|

|

|

| there is oil or water present | 2. |

| Check | Pilot Resistor R2. | ||||||||

|

|

|

| the air supply must be fil- |

|

| See Wiring Diagram |

| ||||||||

|

|

|

| tered | or | the | machine |

|

|

|

|

|

|

| ||

|

|

|

| switched | to | nitrogen | or | 3. |

| The Control Board could be | ||||||

|

|

|

| bottled air. |

|

|

|

|

| faulty. Replace. |

| |||||

|

|

| 3. | Make sure air pressure is |

| 4. |

| Check “Jump Start Diode” - | ||||||||

|

|

|

| 60 to 65 PSI. |

|

|

|

|

| see wiring diagram. |

| |||||

|

|

| 4. | Check spark gap setting - |

|

|

|

|

|

|

| |||||

|

|

|

| .060” - clean if necessary. |

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| |||||||

The | "MALFUNCTION" or | 1. | This is an overcurrent con- | 1. |

| Perform | the | Torch, | ||||||||

"FAULT" LED starts blinking |

| dition caused by a surge of |

|

| Torch |

| Cable | Assembly, | ||||||||

during cutting or gouging. |

| current the machine is not |

|

| and Internal | Trigger and | ||||||||||

|

|

|

| designed |

| to | handle. |

|

| Safety Circuit Tests. |

| |||||

|

|

|

| Release | the | torch trigger |

|

|

|

|

|

|

| |||

|

|

|

| and resume | cutting | or | 2. |

| Perform | the | Transistor | |||||

|

|

|

| gouging. |

|

|

|

|

|

| Module Test. |

|

| |||

|

|

| 2. | Check | torch | consumables | 3. |

| Perform the Main Trans- | |||||||

|

|

|

| for wear - replace if neces- |

|

| former Test. |

|

| |||||||

|

|

|

| sary. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4. |

| The Control Board could be | ||||

|

|

|

|

|

|

|

|

|

|

|

| faulty. Replace. |

| |||

|

|

|

|

|

|

| ||||||||||

Pilot arc is OK but cutting arc | 1. | Make sure work cable and | 1. |

| Perform Transistor Module | |||||||||||

will not establish. |

| clamp are secure. |

|

|

| Test. |

|

|

|

| ||||||

|

|

| 2. | Clean any painted or heavily | 2. |

| Perform Power Board Test. | |||||||||

|

|

|

| corroded work surfaces. |

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

| CAUTION |

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed call