Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

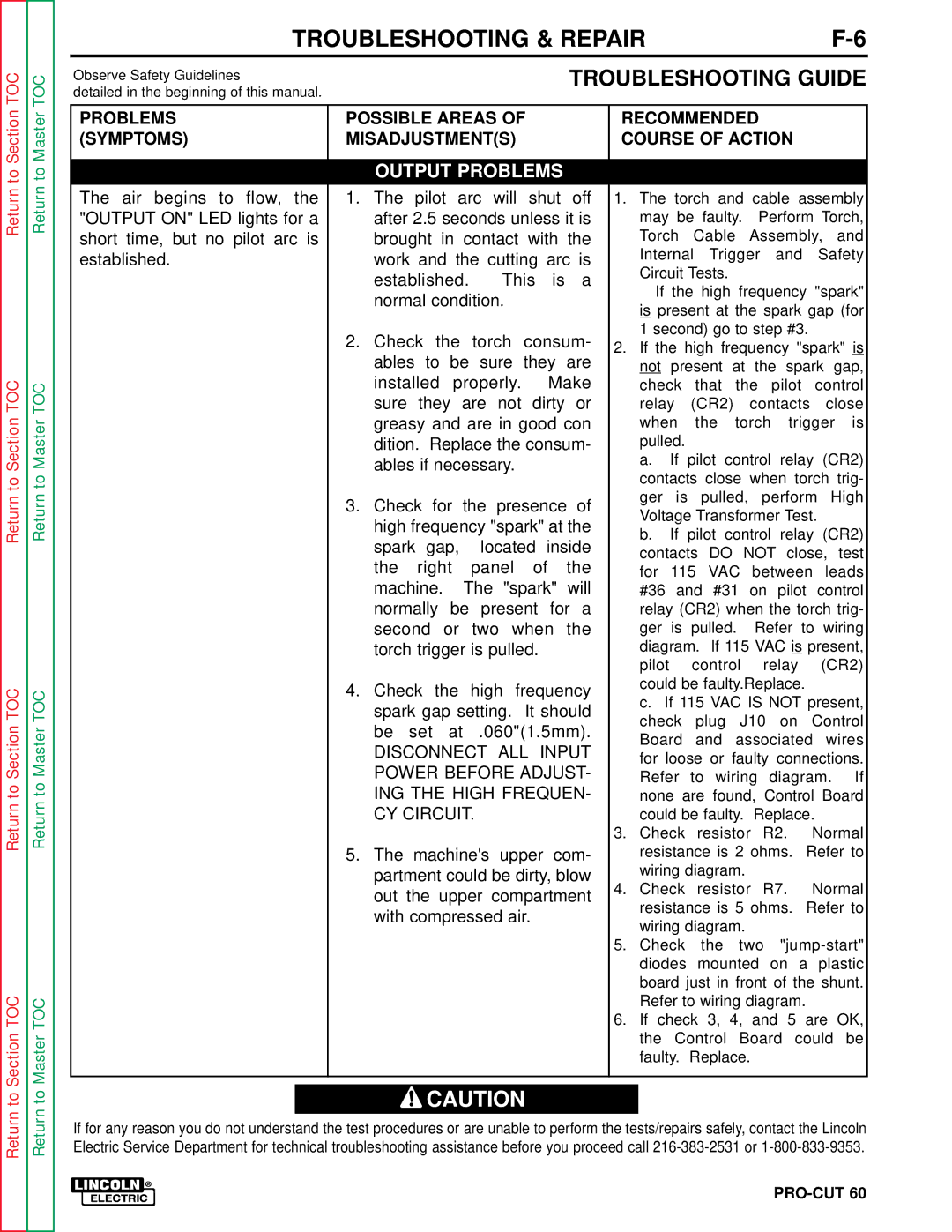

TROUBLESHOOTING & REPAIR |

|

|

|

|

| ||||||||||

Observe Safety Guidelines |

|

|

|

|

| TROUBLESHOOTING GUIDE | |||||||||

detailed in the beginning of this manual. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PROBLEMS | POSSIBLE AREAS OF |

|

| RECOMMENDED |

|

|

| ||||||||

(SYMPTOMS) | MISADJUSTMENT(S) |

|

| COURSE OF ACTION |

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

| OUTPUT PROBLEMS |

|

|

|

|

|

|

|

|

|

| |||

The air begins to flow, the | 1. | The pilot arc will shut | off | 1. | The torch and cable assembly | ||||||||||

"OUTPUT ON" LED lights for a |

| after 2.5 seconds unless it is |

| may be faulty. | Perform Torch, | ||||||||||

short time, but no pilot arc is |

| brought in contact with the |

| Torch | Cable | Assembly, | and | ||||||||

established. |

| work and the cutting arc is |

| Internal Trigger and | Safety | ||||||||||

|

| established. | This | is | a |

| Circuit Tests. |

|

|

|

|

| |||

|

|

| If | the high | frequency "spark" | ||||||||||

|

| normal condition. |

|

|

| ||||||||||

|

|

|

|

| is present at the spark gap (for | ||||||||||

|

|

|

|

|

|

|

| ||||||||

| 2. Check the | torch consum- |

| 1 second) go to step #3. |

|

| |||||||||

| 2. If the high frequency "spark" is | ||||||||||||||

|

| ables to be sure they are | |||||||||||||

|

|

| not present at the spark gap, | ||||||||||||

|

| installed properly. | Make |

| check that the pilot control | ||||||||||

|

| sure they are not dirty or |

| relay | (CR2) | contacts | close | ||||||||

|

| greasy and are in good con |

| when the torch trigger is | |||||||||||

|

| dition. Replace the consum- |

| pulled. |

|

|

|

|

|

| |||||

|

| ables if necessary. |

|

|

| a. | If | pilot control relay | (CR2) | ||||||

|

|

|

|

|

|

|

| contacts close when torch trig- | |||||||

| 3. | Check for the | presence | of |

| ger | is pulled, | perform | High | ||||||

|

| Voltage Transformer Test. |

|

| |||||||||||

|

| high frequency "spark" at the |

|

|

| ||||||||||

|

|

| b. | If | pilot control relay | (CR2) | |||||||||

|

| spark gap, | located | inside |

| ||||||||||

|

|

| contacts DO NOT close, test | ||||||||||||

|

| the right panel of the |

| ||||||||||||

|

|

| for 115 VAC between leads | ||||||||||||

|

| machine. | The | "spark" | will |

| #36 and #31 on pilot control | ||||||||

|

| normally be present for a |

| relay (CR2) when the torch trig- | |||||||||||

|

| second or two when the |

| ger | is | pulled. | Refer | to | wiring | ||||||

|

| torch trigger is pulled. |

|

|

| diagram. If 115 VAC is present, | |||||||||

|

|

|

|

|

|

|

| pilot |

| control | relay |

| (CR2) | ||

| 4. | Check the | high frequency |

| could be faulty.Replace. |

|

| ||||||||

|

| c. If 115 VAC IS NOT present, | |||||||||||||

|

| spark gap setting. It should |

| ||||||||||||

|

|

| check | plug | J10 on | Control | |||||||||

|

| be set at | .060"(1.5mm). |

| |||||||||||

|

|

| Board | and | associated | wires | |||||||||

|

| DISCONNECT ALL INPUT |

| ||||||||||||

|

|

| for loose or faulty connections. | ||||||||||||

|

| POWER BEFORE ADJUST- |

| ||||||||||||

|

|

| Refer | to wiring diagram. | If | ||||||||||

|

| ING THE HIGH FREQUEN- |

| none are found, Control Board | |||||||||||

|

| CY CIRCUIT. |

|

|

|

| could be faulty. Replace. |

|

| ||||||

|

|

|

|

|

|

| 3. | Check | resistor | R2. | Normal | ||||

| 5. | The machine's upper com- |

| resistance is 2 ohms. | Refer to | ||||||||||

|

| partment could be dirty, blow | 4. | wiring diagram. | R7. | Normal | |||||||||

|

| out the upper compartment | Check | resistor | |||||||||||

|

|

| resistance is 5 ohms. Refer to | ||||||||||||

|

| with compressed air. |

|

|

| ||||||||||

|

|

|

|

| wiring diagram. |

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

| 5. | Check the two | |||||||

|

|

|

|

|

|

|

| diodes mounted on a plastic | |||||||

|

|

|

|

|

|

|

| board just in front of the shunt. | |||||||

|

|

|

|

|

|

|

| Refer to wiring diagram. |

|

| |||||

|

|

|

|

|

|

| 6. If check 3, 4, | and 5 | are | OK, | |||||

|

|

|

|

|

|

|

| the Control Board could be | |||||||

|

|

|

|

|

|

|

| faulty. Replace. |

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed call