INSTALLATION | ||

|

|

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

MOUNTING LOCATION

The

POWER SOURCE CONNECTIONS

Use the type of power source required for the specific welding application.

![]() CAUTION

CAUTION

Never operate a Lincoln Squirt welder wire feeder with a power source that has a jumper from #2 to #4 on the terminal strip, or with a power source without a contactor. To do so would defeat the ground lead protector circuit and could result in overheating of the electrical ground circuit to the wire feeder.

____________________________________

A constant voltage power source is required for Innershield electrode and other open arc welding. It is often preferred for small, single pass submerged arc welds at fast travel speeds.

Formerly, a constant current power source was rec- ommended for most submerged arc welding. With the innovation of the new DC power sources, a special mode (CV

The

The

Refer to the “Input Cable Connections” section when connecting the

LN-8N AND LN-8NE

Use a constant voltage type power source. If the

1.If using a

2.Connect the

3.Connect a work lead of sufficient size and length per Table A.1, between the appropriate output terminal on the power source and the work. Ensure the connection to the work makes tight

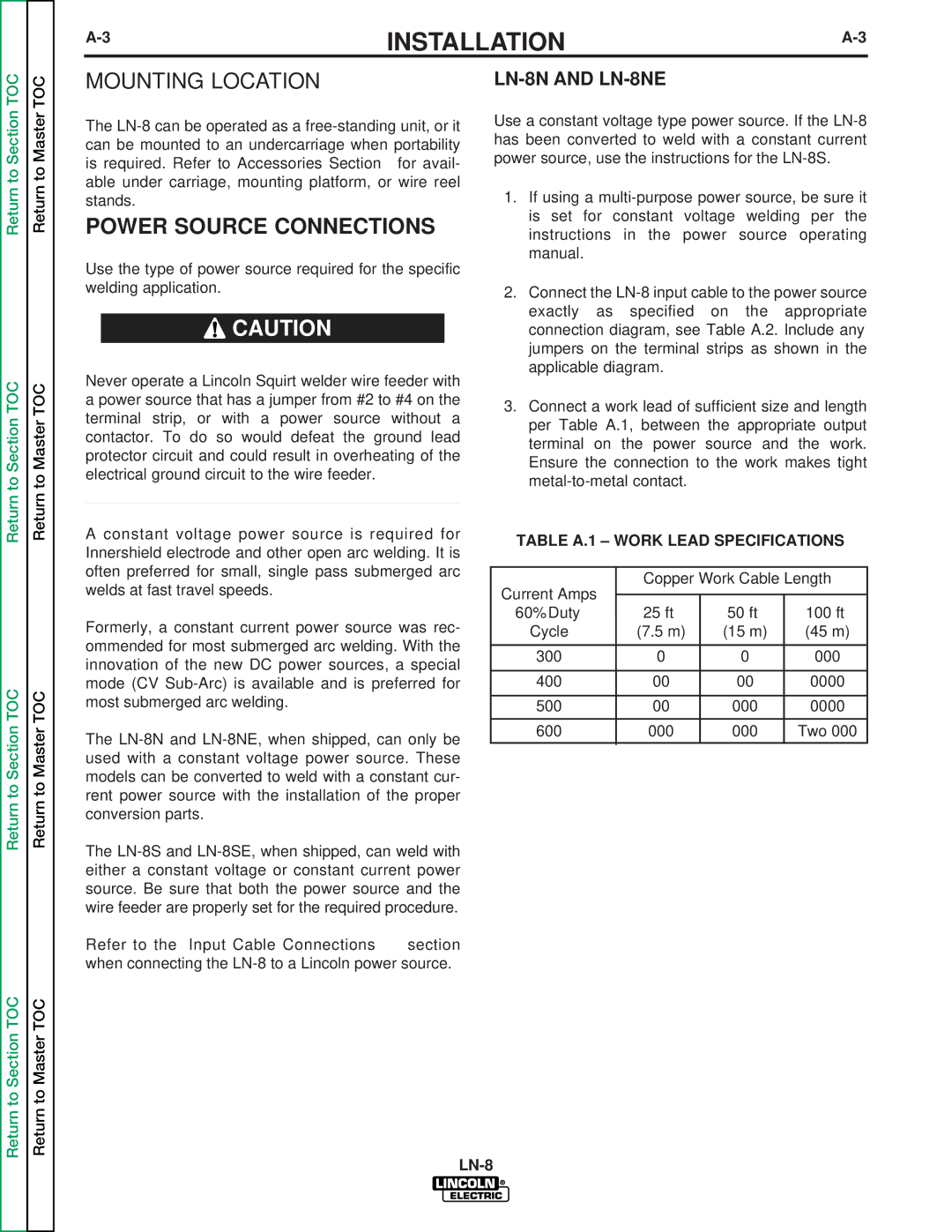

TABLE A.1 – WORK LEAD SPECIFICATIONS

Copper Work Cable Length

Current Amps |

|

|

|

60% Duty | 25 ft | 50 ft | 100 ft |

Cycle | (7.5 m) | (15 m) | (45 m) |

300 | 0 | 0 | 000 |

400 | 00 | 00 | 0000 |

500 | 00 | 000 | 0000 |

600 | 000 | 000 | Two 000 |