INSTALLATION

Return to Master TOC

to Master TOC

GAS INPUT CONNECTIONS

Supply the

•Supply pressure must be between 80 psi and 150 psi.

•Flow rate should be approximately 6.0 cfm (170 I/min.).

NOTE: Oil in the air supply to the

•Connect the gas supply to the

•Compressed gas should be supplied to the fitting connection mounted on the filter at the rear of the machine. If necessary, this fitting can be removed allowing plumbing access through the 1/4 in. (6.4mm) NPT input port on the filter body.

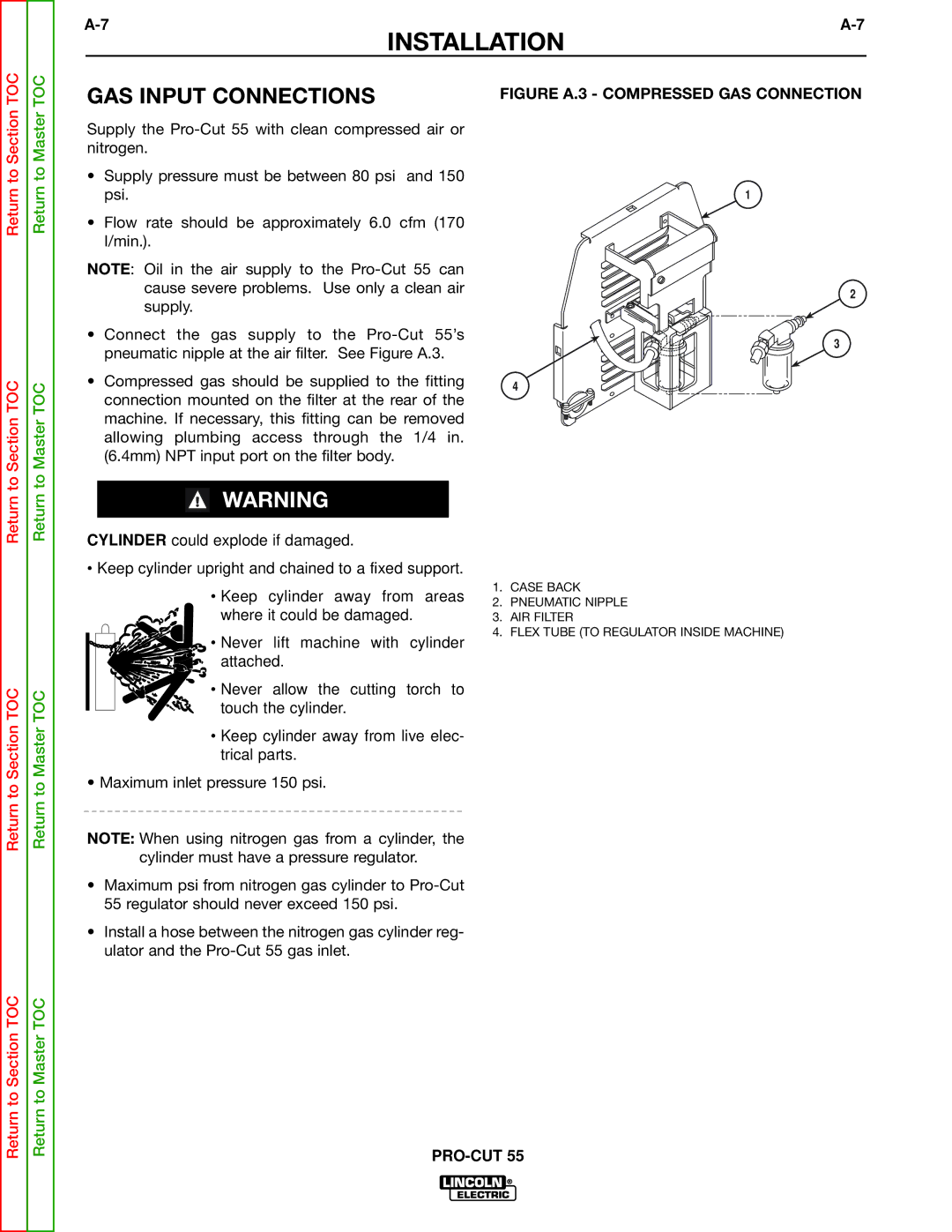

FIGURE A.3 - COMPRESSED GAS CONNECTION

1

2

3

4

Return to Section TOC

Return to Section TOC

Return to Section TOC

WARNING

CYLINDER could explode if damaged.

• Keep cylinder upright and chained to a fixed support.

• Keep cylinder away from areas where it could be damaged.

![]()

![]()

![]()

![]()

![]() • Never lift machine with cylinder

• Never lift machine with cylinder ![]()

![]()

![]()

![]()

![]()

![]() attached.

attached.

• Never allow the cutting torch to touch the cylinder.

•Keep cylinder away from live elec- trical parts.

•Maximum inlet pressure 150 psi.

NOTE: When using nitrogen gas from a cylinder, the cylinder must have a pressure regulator.

•Maximum psi from nitrogen gas cylinder to

•Install a hose between the nitrogen gas cylinder reg- ulator and the

1.CASE BACK

2.PNEUMATIC NIPPLE

3.AIR FILTER

4.FLEX TUBE (TO REGULATOR INSIDE MACHINE)

Return to Section TOC

Return to Master TOC