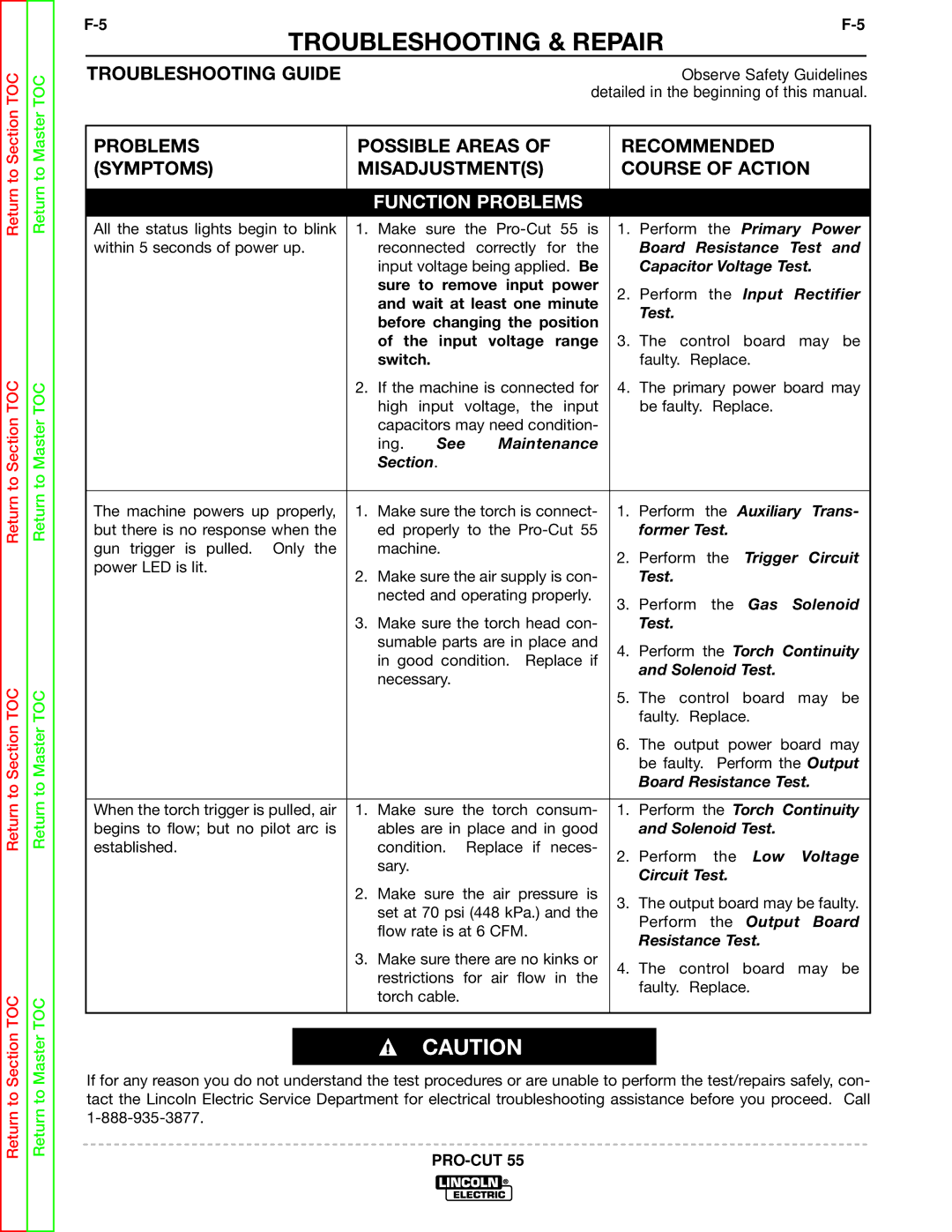

| TROUBLESHOOTING & REPAIR | |

| TROUBLESHOOTING GUIDE | Observe Safety Guidelines |

|

| detailed in the beginning of this manual. |

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED |

| ||||||||

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | |||||||||

|

|

|

|

|

|

|

| ||||

|

| FUNCTION PROBLEMS |

|

|

|

|

| ||||

All the status lights begin to blink | 1. Make | sure | the | 1. | Perform | the | Primary Power | ||||

within 5 seconds of power up. |

| reconnected correctly for the |

| Board Resistance | Test and | ||||||

|

| input voltage being applied. Be |

| Capacitor Voltage Test. | |||||||

|

| sure to remove input power | 2. Perform the Input Rectifier | ||||||||

|

| and wait at least one minute | |||||||||

|

|

| Test. |

|

|

| |||||

|

| before changing the position |

|

|

|

| |||||

|

|

|

|

|

|

| |||||

|

| of the input voltage range | 3. | The control board may be | |||||||

|

| switch. |

|

|

|

| faulty. Replace. |

| |||

| 2. | If the machine is connected for | 4. | The primary power board may | |||||||

|

| high input voltage, the input |

| be faulty. Replace. |

| ||||||

|

| capacitors may need condition- |

|

|

|

|

| ||||

|

| ing. | See | Maintenance |

|

|

|

|

| ||

|

| Section. |

|

|

|

|

|

|

|

| |

|

|

|

| ||||||||

The machine powers up properly, | 1. Make sure the torch is connect- | 1. | Perform the Auxiliary Trans- | ||||||||

but there is no response when the |

| ed properly to the |

| former Test. |

|

| |||||

gun trigger is pulled. Only the |

| machine. |

|

|

| 2. | Perform | the | Trigger Circuit | ||

power LED is lit. |

|

|

|

|

|

| |||||

2. Make sure the air supply is con- |

| Test. |

|

|

| ||||||

|

|

|

|

| |||||||

|

| nected and operating properly. | 3. | Perform | the | Gas | Solenoid | ||||

|

|

|

|

|

|

| |||||

| 3. | Make sure the torch head con- |

| Test. |

|

|

| ||||

|

| sumable parts are in place and | 4. | Perform the Torch Continuity | |||||||

|

| in good condition. | Replace if | ||||||||

|

|

| and Solenoid Test. |

| |||||||

|

| necessary. |

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| 5. | The control | board | may be | |

|

|

|

|

|

|

|

| faulty. Replace. |

| ||

|

|

|

|

|

|

| 6. | The output power board may | |||

|

|

|

|

|

|

|

| be faulty. Perform the Output | |||

|

|

|

|

|

|

|

| Board Resistance Test. | |||

|

|

|

|

|

|

| |||||

When the torch trigger is pulled, air | 1. Make | sure | the | torch consum- | 1. | Perform the Torch Continuity | |||||

begins to flow; but no pilot arc is |

| ables are in place and in good |

| and Solenoid Test. |

| ||||||

established. |

| condition. | Replace if neces- | 2. | Perform | the | Low | Voltage | |||

|

| sary. |

|

|

|

| |||||

|

|

|

|

|

|

| Circuit Test. |

|

| ||

|

|

|

|

|

|

|

|

|

| ||

| 2. | Make | sure | the | air | pressure is | 3. The output board may be faulty. | ||||

|

| set at 70 psi (448 kPa.) and the | |||||||||

|

|

| Perform | the | Output Board | ||||||

|

| flow rate is at 6 CFM. |

| ||||||||

|

|

| Resistance Test. |

| |||||||

|

|

|

|

|

|

|

|

| |||

| 3. Make sure there are no kinks or | 4. | The control board may be | ||||||||

|

| restrictions | for | air | flow in the | ||||||

|

|

| faulty. Replace. |

| |||||||

|

| torch cable. |

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call