|

|

| |||||

|

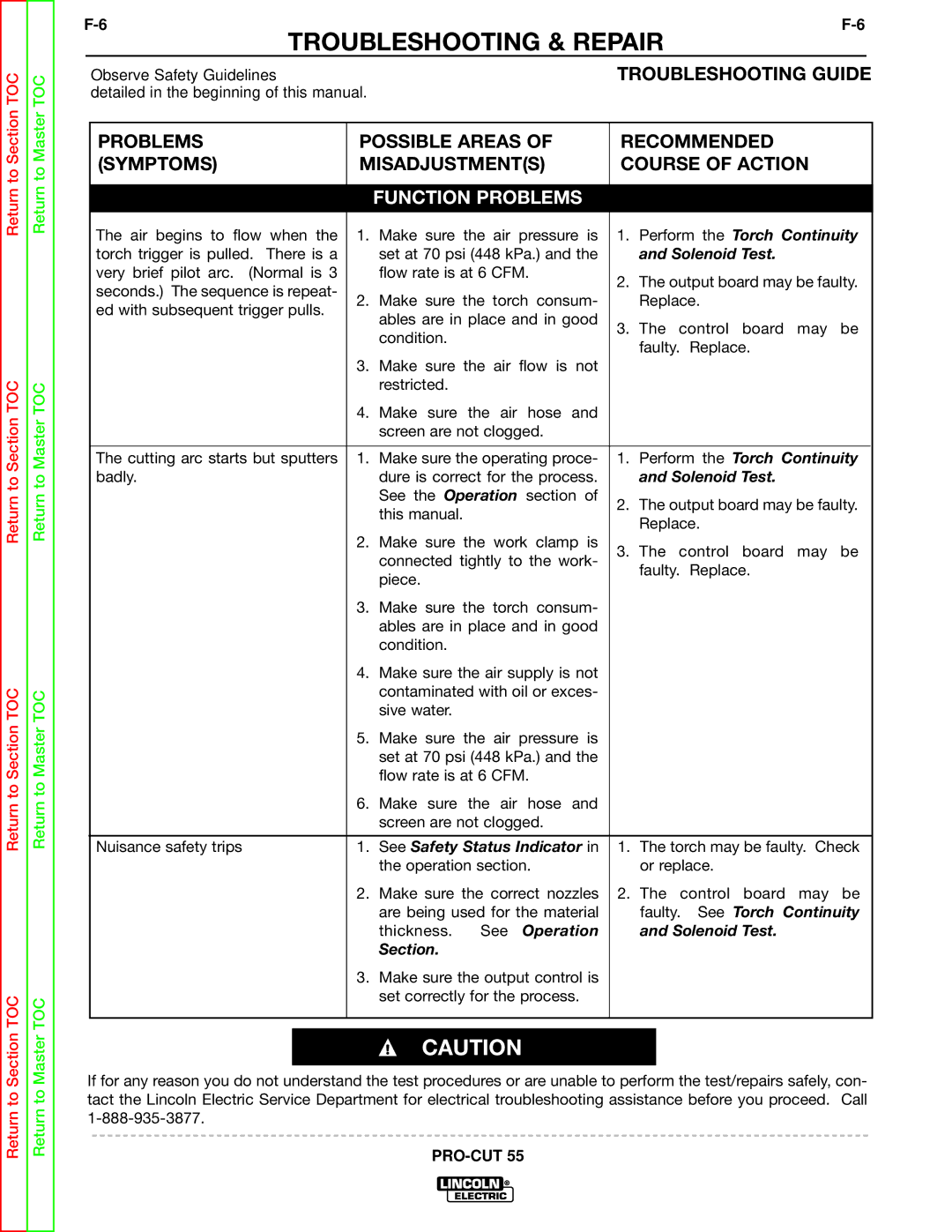

| TROUBLESHOOTING & REPAIR |

| ||||

|

| Observe Safety Guidelines |

|

| TROUBLESHOOTING GUIDE | ||

|

| detailed in the beginning of this manual. |

|

|

|

| |

|

|

|

|

| |||

|

| PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | |||

|

| (SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | |||

|

|

|

|

|

|

|

|

|

|

|

| FUNCTION PROBLEMS |

|

|

|

|

| The air begins to flow when the | 1. | Make sure the air pressure is | 1. Perform the Torch Continuity | ||

|

| torch trigger is pulled. There is a |

| set at 70 psi (448 kPa.) and the |

| and Solenoid Test. | |

|

| very brief pilot arc. (Normal is 3 |

| flow rate is at 6 CFM. | 2. The output board may be faulty. | ||

|

| seconds.) The sequence is repeat- |

|

| |||

|

| 2. | Make sure the torch consum- |

| Replace. | ||

|

| ed with subsequent trigger pulls. |

| ||||

|

|

| ables are in place and in good |

|

|

| |

|

|

|

| 3. | The control board may be | ||

|

|

|

| condition. | |||

|

|

|

|

| faulty. Replace. | ||

|

|

|

|

|

| ||

|

|

| 3. | Make sure the air flow is not |

|

|

|

|

|

|

| restricted. |

|

|

|

|

|

| 4. | Make sure the air hose and |

|

|

|

|

|

|

| screen are not clogged. |

|

|

|

|

|

|

|

|

| ||

|

| The cutting arc starts but sputters | 1. | Make sure the operating proce- | 1. Perform the Torch Continuity | ||

|

| badly. |

| dure is correct for the process. |

| and Solenoid Test. | |

|

|

|

| See the Operation section of | 2. The output board may be faulty. | ||

|

|

|

| this manual. | |||

|

|

|

|

| Replace. | ||

|

|

|

|

|

| ||

|

|

| 2. | Make sure the work clamp is | 3. | The control board may be | |

|

|

|

| connected tightly to the work- | |||

|

|

|

|

| faulty. Replace. | ||

|

|

|

| piece. |

| ||

|

|

|

|

|

|

| |

|

|

| 3. | Make sure the torch consum- |

|

|

|

|

|

|

| ables are in place and in good |

|

|

|

|

|

|

| condition. |

|

|

|

|

|

| 4. | Make sure the air supply is not |

|

|

|

|

|

|

| contaminated with oil or exces- |

|

|

|

|

|

|

| sive water. |

|

|

|

|

|

| 5. | Make sure the air pressure is |

|

|

|

|

|

|

| set at 70 psi (448 kPa.) and the |

|

|

|

|

|

|

| flow rate is at 6 CFM. |

|

|

|

|

|

| 6. | Make sure the air hose and |

|

|

|

|

|

|

| screen are not clogged. |

|

|

|

|

|

|

|

|

|

| |

|

| Nuisance safety trips | 1. | See Safety Status Indicator in | 1. | The torch may be faulty. Check | |

|

|

|

| the operation section. |

| or replace. | |

|

|

| 2. | Make sure the correct nozzles | 2. The control board may be | ||

|

|

|

| are being used for the material |

| faulty. See Torch Continuity | |

|

|

|

| thickness. See Operation |

| and Solenoid Test. | |

|

|

|

| Section. |

|

|

|

|

|

| 3. | Make sure the output control is |

|

|

|

|

|

|

| set correctly for the process. |

|

|

|

|

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call