Return to Section TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR

AIR/GAS SOLENOID TEST (continued)

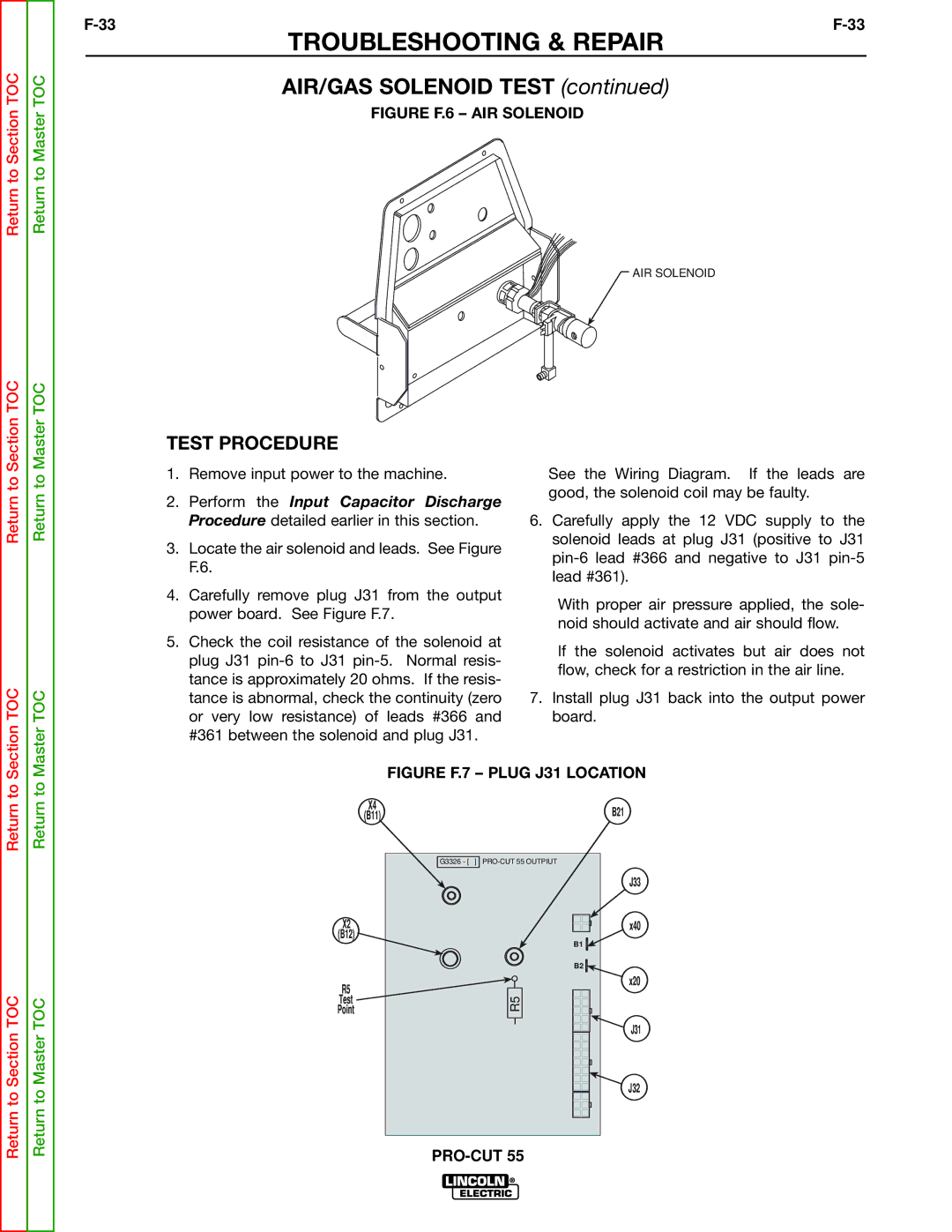

FIGURE F.6 – AIR SOLENOID

AIR SOLENOID

Return to Section TOC

Section TOC

Return to Master TOC

Master TOC

TEST PROCEDURE

1.Remove input power to the machine.

2.Perform the Input Capacitor Discharge Procedure detailed earlier in this section.

3.Locate the air solenoid and leads. See Figure F.6.

4.Carefully remove plug J31 from the output power board. See Figure F.7.

5.Check the coil resistance of the solenoid at plug J31

See the Wiring Diagram. If the leads are good, the solenoid coil may be faulty.

6.Carefully apply the 12 VDC supply to the solenoid leads at plug J31 (positive to J31

With proper air pressure applied, the sole- noid should activate and air should flow.

If the solenoid activates but air does not flow, check for a restriction in the air line.

7.Install plug J31 back into the output power board.