|

| ||

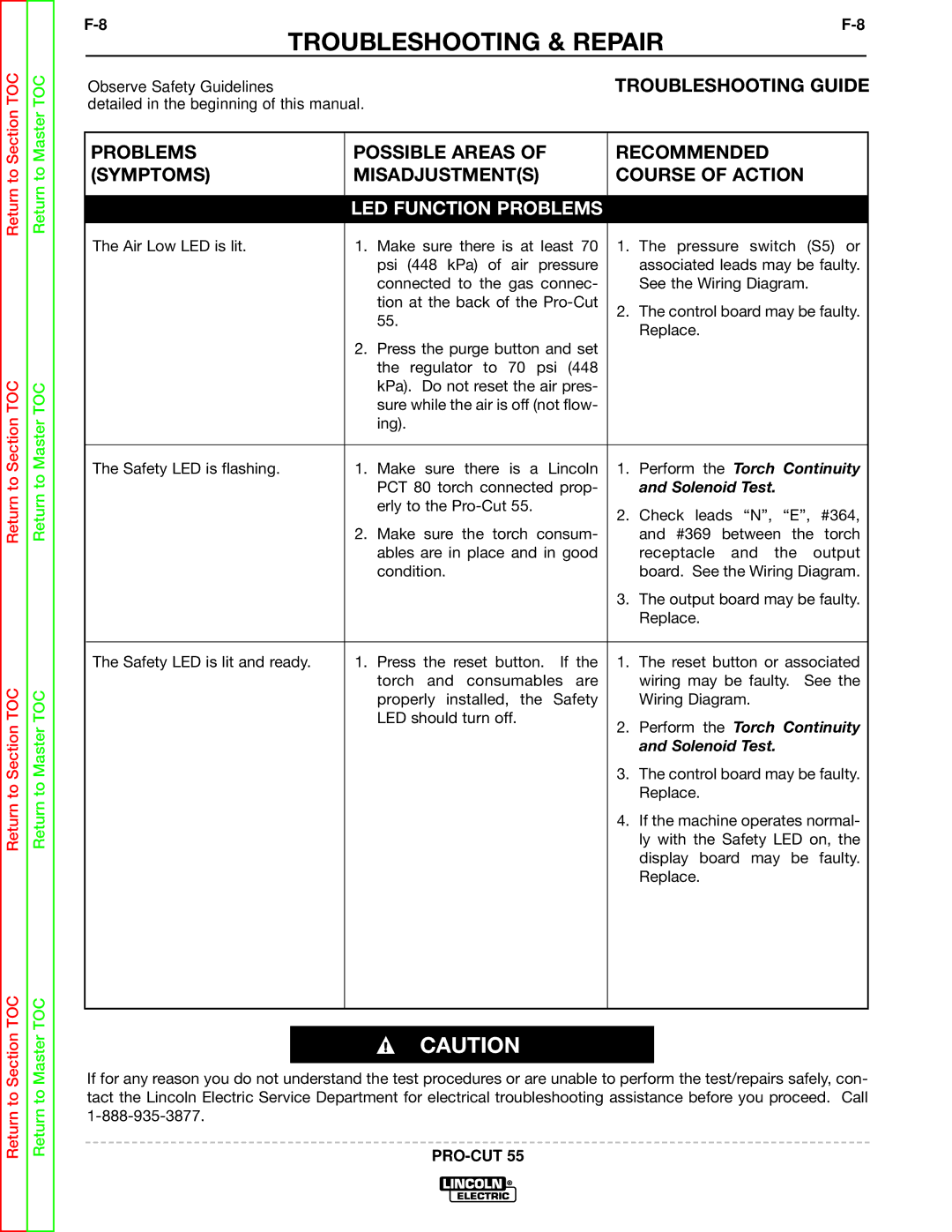

TROUBLESHOOTING & REPAIR | |||

Observe Safety Guidelines |

| TROUBLESHOOTING GUIDE | |

detailed in the beginning of this manual. |

|

| |

|

|

| |

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | |

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | |

|

|

|

|

| LED FUNCTION PROBLEMS |

|

|

The Air Low LED is lit. | 1. Make sure there is at least 70 | 1. | The pressure switch (S5) or |

| psi (448 kPa) of air pressure |

| associated leads may be faulty. |

| connected to the gas connec- |

| See the Wiring Diagram. |

| tion at the back of the | 2. | The control board may be faulty. |

| 55. | ||

|

| Replace. | |

|

|

| |

| 2. Press the purge button and set |

|

|

| the regulator to 70 psi (448 |

|

|

| kPa). Do not reset the air pres- |

|

|

| sure while the air is off (not flow- |

|

|

| ing). |

|

|

|

|

|

|

The Safety LED is flashing. | 1. Make sure there is a Lincoln | 1. | Perform the Torch Continuity |

| PCT 80 torch connected prop- |

| and Solenoid Test. |

| erly to the | 2. | Check leads “N”, “E”, #364, |

|

| ||

| 2. Make sure the torch consum- |

| and #369 between the torch |

| ables are in place and in good |

| receptacle and the output |

| condition. |

| board. See the Wiring Diagram. |

|

| 3. | The output board may be faulty. |

|

|

| Replace. |

|

|

|

|

The Safety LED is lit and ready. | 1. Press the reset button. If the | 1. | The reset button or associated |

| torch and consumables are |

| wiring may be faulty. See the |

| properly installed, the Safety |

| Wiring Diagram. |

| LED should turn off. | 2. | Perform the Torch Continuity |

|

| ||

|

|

| and Solenoid Test. |

|

| 3. | The control board may be faulty. |

|

|

| Replace. |

|

| 4. | If the machine operates normal- |

|

|

| ly with the Safety LED on, the |

|

|

| display board may be faulty. |

|

|

| Replace. |

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call