R.4104.A

REASSEMBLY PROCEDURE | 2. Substage Unit |

|

|

2.Substage Unit

For reassembly, reverse the disassembly procedure, taking the cautions as below:

1)The positions to be oiled or cemented should be cleaned and dried, beforehand. Use only the specified lubricant :md adhesive.

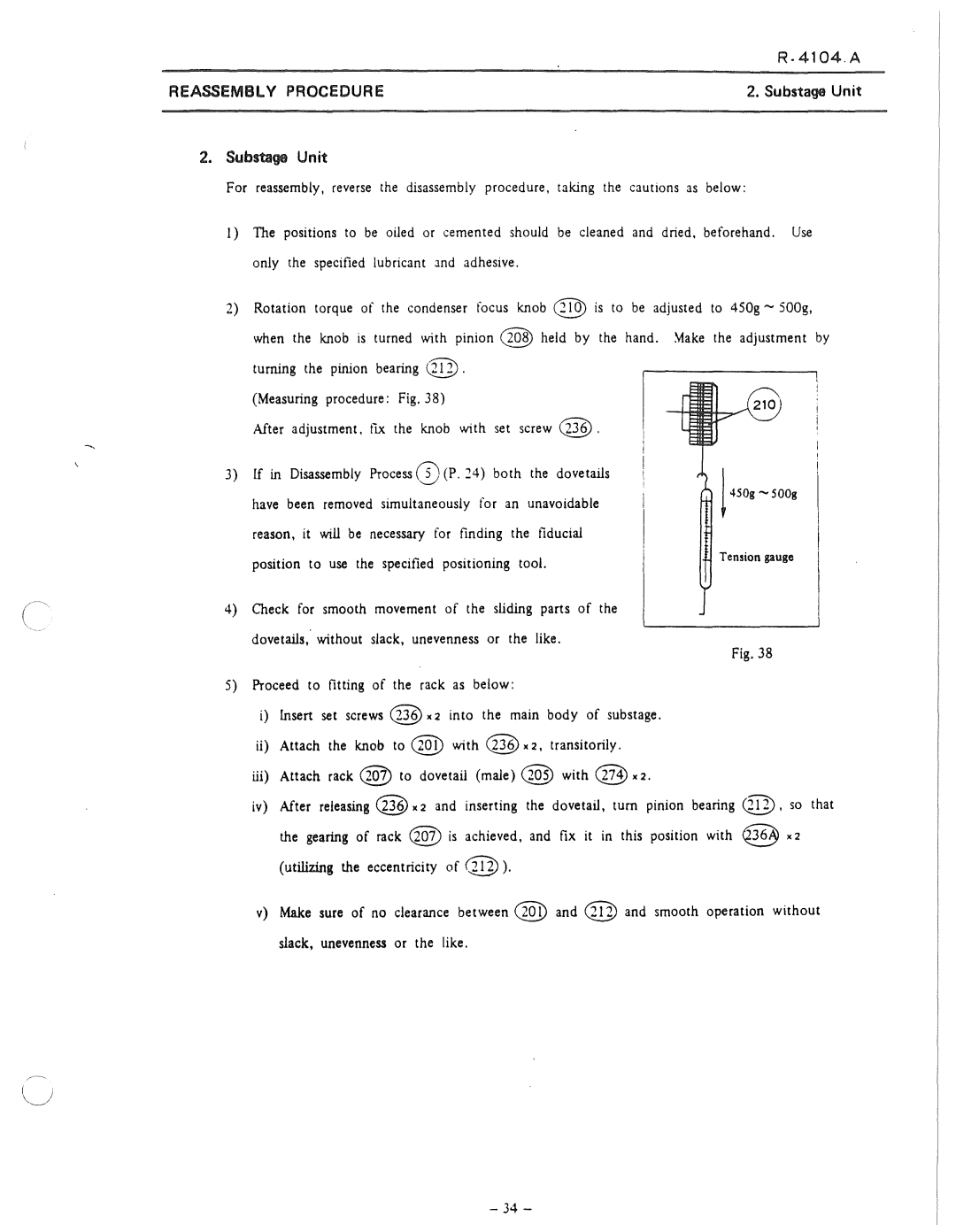

2)Rotation torque of the condenser focus knob @ is to be adjusted to 450g - 500g, when the knob is turned with pinion @ held by the hand. \1ake the adjustment by

turning the pinion bearing @ . (Measuring procedure: Fig. 38)

After adjustment, fix the knob with set screw @ .

3)If in Disassembly Process (D (P. 24) both the dovetails have been removed simultaneousty for an unavoidable reason, it will be necessary for finding the fiducial position to use the specified positioning too!.

4)Check for smooth movement of the sliding parts of the dovetails, without slack, unevenness or the like.

Tension gauge

Fig. 38

5)Proceed to fitting of the rack as below:

i)Insert set screws @x2 into the main body of substage.

ii)Attach the knob to @ with @x 2, transitorily.

üi) Attach rack@ to dovetail (male)@ with @x2.

iv)After releasing @ x 2 and inserting the dovetail, tum pinion bearing @ , so that lhe gearing of rack @ is achieved, and fix it in this position with @ x 2 (utilizíng lhe eccentricity of @ ).

v)Make sure of no clearance between @ and @ and smooth operation without slack, unevenness or the like.

- 34 -