REASSEMBL Y PROCEDURE | 1. B·tube |

|

|

REASSEMBLY PROCEDURE

Before reassembly, clear off dírt from the lenses, prisms and metal parts.

1.B-tube

1)Insert the lens chamber G) (with @ and @ ins1de, to be positioned as ~~ thicker), and screw in retaining ring G) Applying adhesive No. 350, attach G) to G) aft;;';djusting the

optical axis (P. 40).

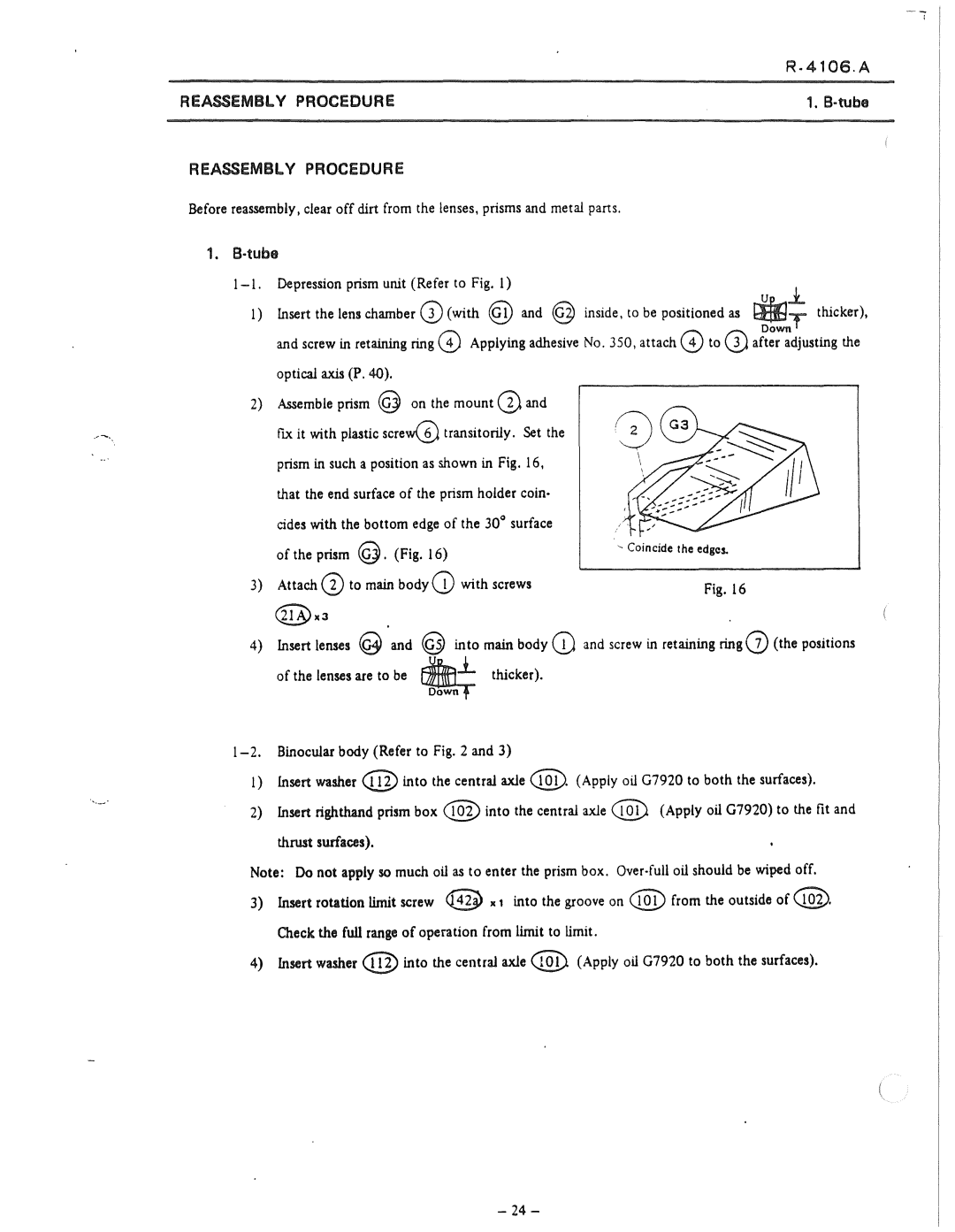

2)Assemble prism @ on the mount (D and

n.x it with plastic screw@ transitorily. Set the |

|

| ||

| prism in such a position as shown in Fig. 16, |

|

| |

| that the end surface of the prism holder coin· |

|

| |

| cides with the bottom edge of the 30° surface |

|

| |

| of the prism @. (Fig. 16) | ' | Coincide the edgcs. | |

|

|

| ||

3) | Attach G) to main body G) with screws |

|

| |

| Fig. 16 | |||

| ~x3 |

|

|

|

4) | Insert lemes ª and | @ into main body (D and screw in retaining ringG) (the positions | ||

| of the lenses are to be | ~J.. thicker). |

|

|

|

| ~ |

|

|

1)Insert washer@ into the central axle (@J). (Apply oil G7920 to both the surfaces).

2)Insert righthand prism box c:@D into the central a.xle e@ (Apply oil G7920) to the fit and

thrwt surfaces).

Note: Do not apply so much oil as to enter the prism box.

3)Insert rotation limit screw ~ x 1 into the groove on e@ from the outside of@ . Check the full range of operation from limit to limit.

4)Insert washer@ into the central axle (@D. (Apply oil G7920 to both the surfaces).

- 24-