R-4104A

ADJUSTMENT | 5. Centering the Tube Attaching and Stage Attaching Parts |

|

|

5.Centering the Tube Attaching and Stage Attaching Parts

To perform the centering, use the three to ois, as foilows:

|

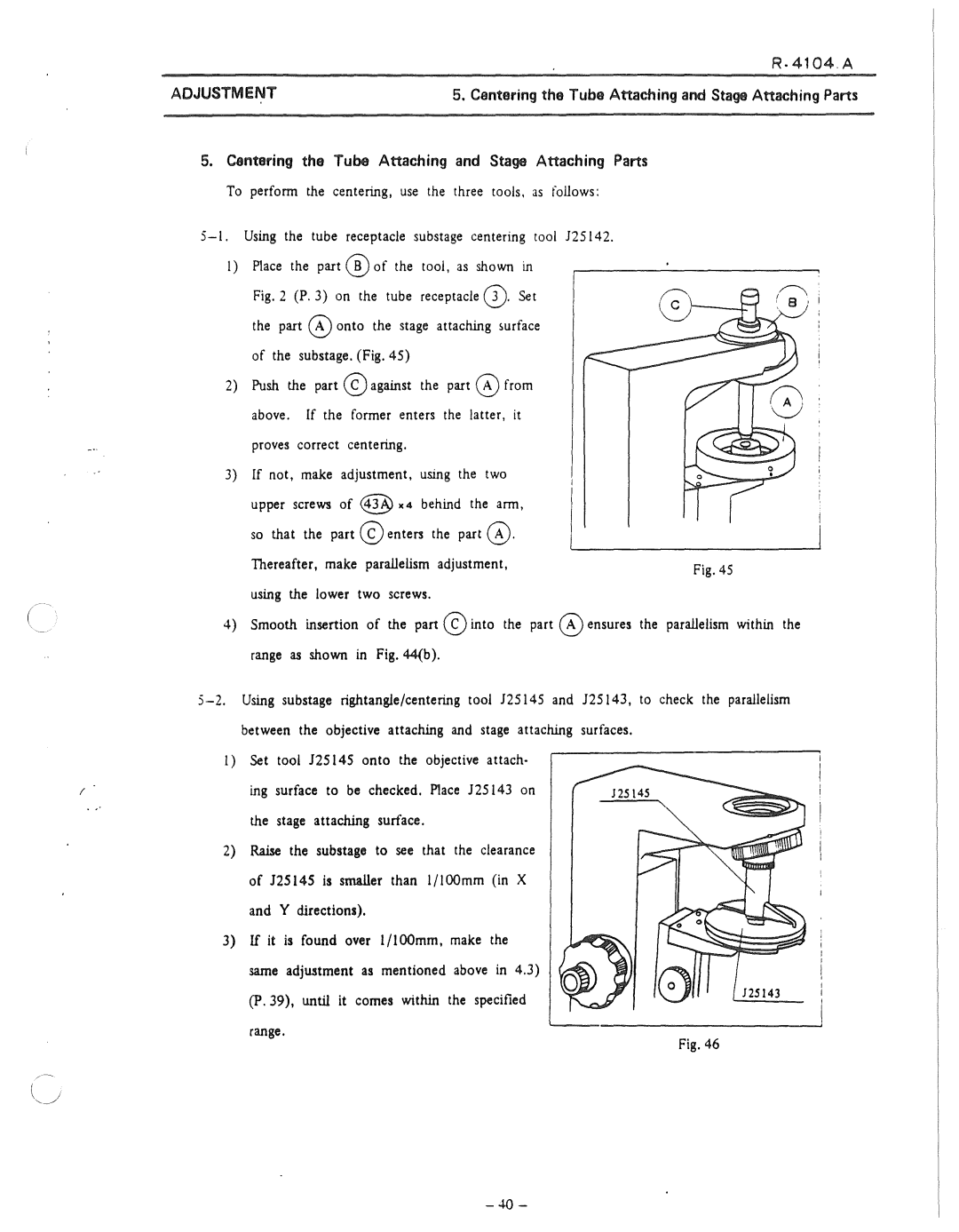

| Fig. 2 (P. 3) on the tube receptacle 0·Set |

| ||

|

| the part @ onto the stage attaching mrface |

| ||

|

| of the substage. (Fig. 45) |

| ||

| 2) | Push the part @) against the part @ from |

| ||

|

| above. If the former enters the latter, it |

| ||

|

| proves correct centering. |

| ||

| 3) If not, make adjustment, using the two |

| |||

|

| upper screws of ~ •4 behind the arm, |

| ||

|

| so that the part@ enters the part @. |

| ||

|

|

|

|

| |

|

| Thereafter, make parallelism adjustment, | Fig. 45 | ||

|

|

|

|

| |

|

| using the lower two screws. |

| ||

( | 4) | Smooth insertion of the part @ into the part @ ensures the parailelism within the | |||

| |||||

|

| range as shown in Fig. 44(b ). |

| ||

|

| ||||

|

| between the objective attaching and stage attaching surfaces. |

| ||

| 1) Set tool 125145 onto the objective attach· |

| |||

| ( | ing | surface to be checked. Place 125143 on |

| |

|

| the | stage attaching surface. |

| |

| 2) | Raise the substage to see that the clearance |

| ||

|

| of 125145 is smaller than 1/1 OOmm (in X |

| ||

|

| and | Y directions). |

| |

| 3) If it is found over l/IOOmm, make the |

| |||

|

| sarne adjustment as mentioned above in 4.3) |

| ||

|

| (P. 39), until it comes within the specified |

| ||

range.

Fig. 46

- 40 -