'

|

|

REASSEMBL V PROCEDURE | 3. Arm Unit |

|

|

3.Arm Unit (OPTIPHOT, LABOPHOT)

For reassembly, reverse the disassembly procedure, taking the cautions as below:

l)Clean and dry the parts to be oiled or cemented as shown in Fig. 29, 30, and then apply the specified lubricant and adhesive.

2)If in Disassembly Procedure 7 (P. 22) the lefthand race@ on the fiducial side has been dismounted for an unavoidable reason, use the right one as fiducial (Assuming that both the right and left races have not been dismounted).

3)Proceed to adjustment of the roiler races as below:

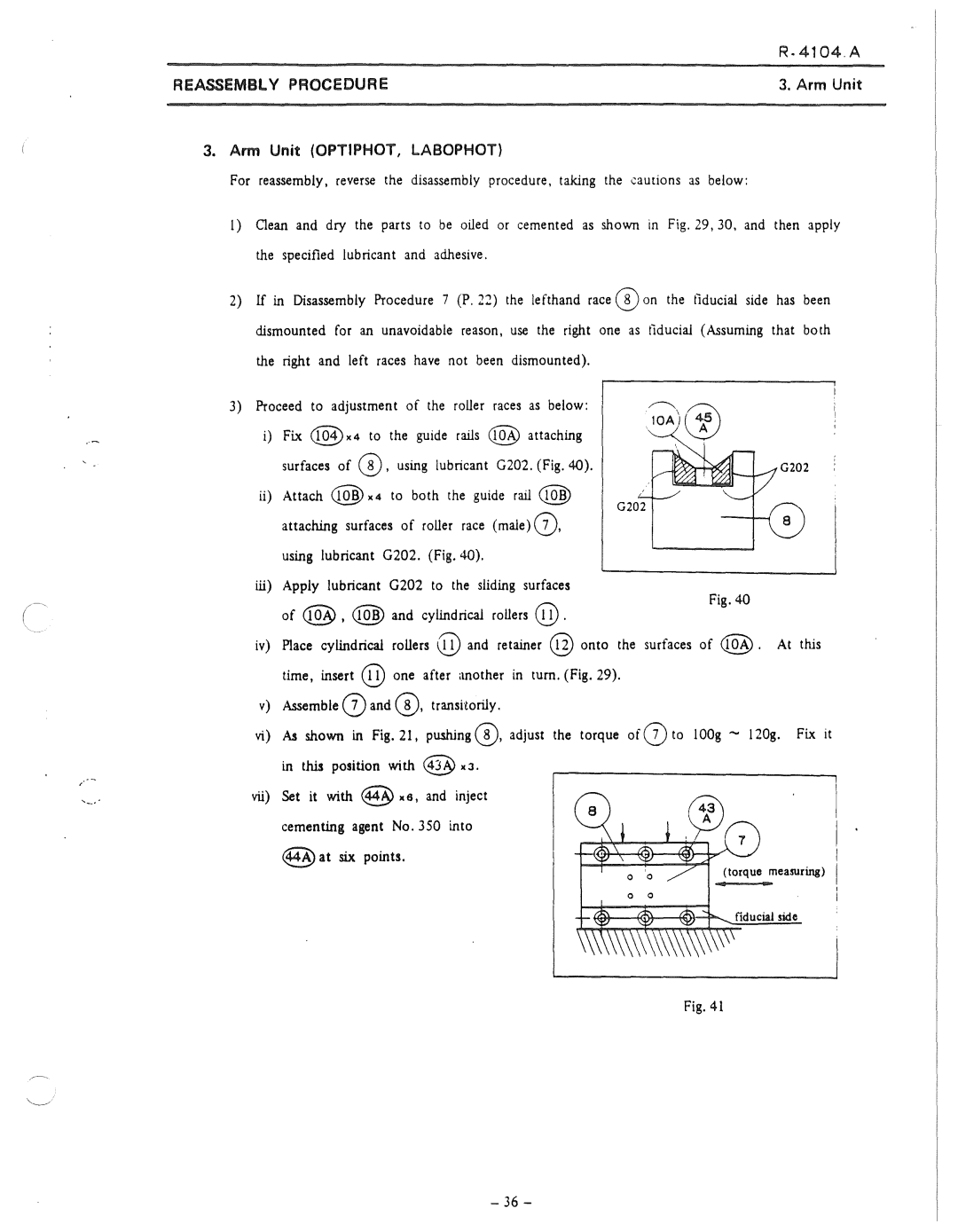

i) Fix @x4 to the guide rails @ attaching |

|

surfaces of @, using lubricant G202. (Fig. 40). | G202 |

ii)Attach @x4 to both the guide rail @

| (male) G), | G202 |

|

| ||||

|

| |||||||

attaching surfaces of roller race |

|

|

|

| 8 |

|

| |

|

| |||||||

using lubricant G202. (Fig. 40). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

ili) Apply lubricant G202 to the sliding surfaces |

|

|

|

|

|

|

| |

| Fig. 40 | |||||||

of <@ , @ and cylindrical | rollers @ . |

| ||||||

|

|

|

|

|

|

| ||

iv)Place cylindrical rollers @ and retainer @ onto the surfaces of e@ . At this time, insert @ one after another in tum. (Fig. 29).

v)Assemble (j) and @, transitorily.

vi) As shown in Fig. 21, pushing @, adjust the torque of (j) to IOOg - l 20g. Fix it in this position with <@ xJ.

vii)Set it with <@ x6, and inject cementing agent No. 350 into

~ at six points.

(Iorque mearuring)

fiducial ooe

Fig. 41

- 36 -