R-4108.A

REASSEMBLING PROCEDURE

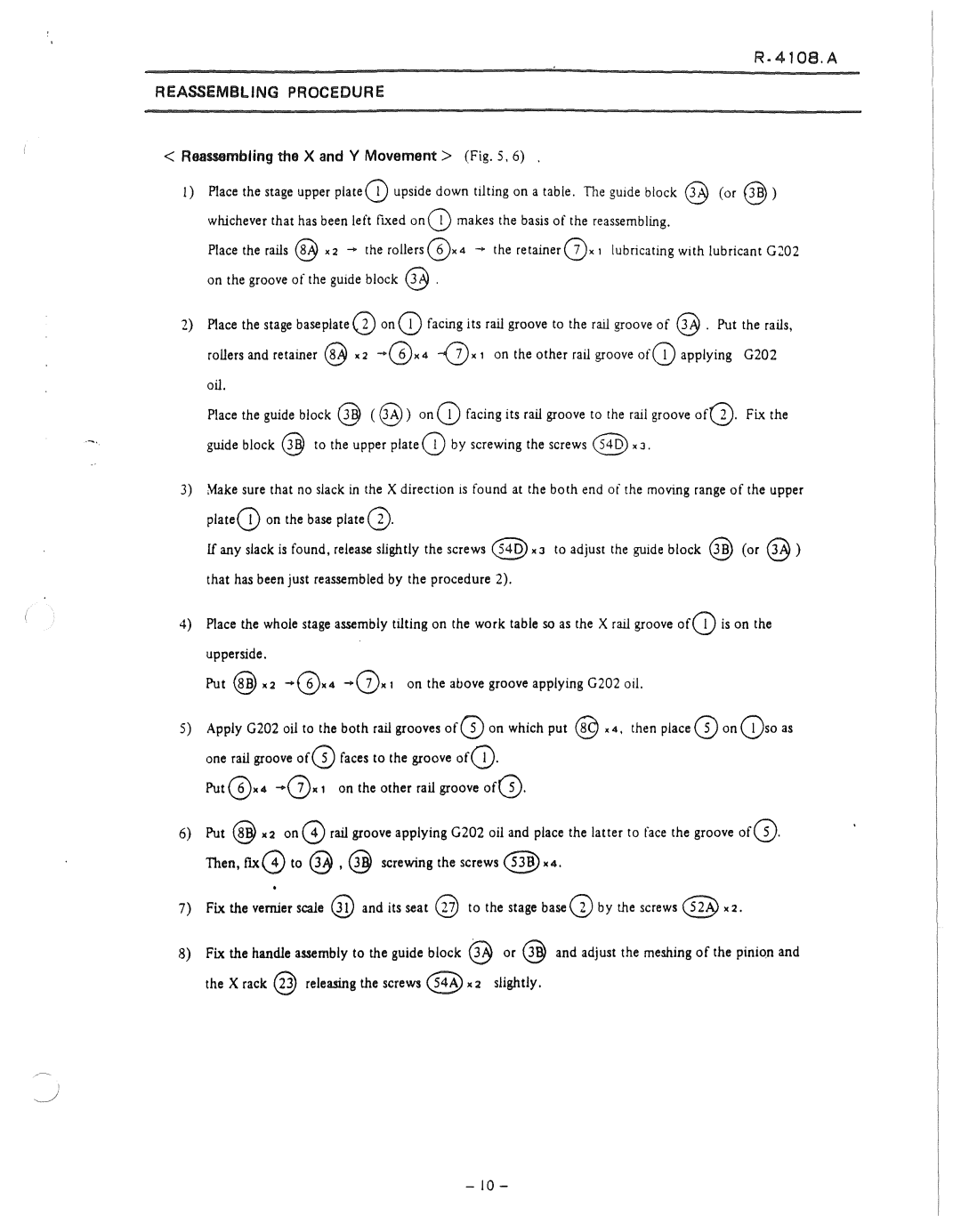

<Reassembling me X and Y Movement > (Fig. s. 6) .

1)Place the stage upper pia te Q upside down tilting on a table. The guide block @ (or @ ) whichever that has been left fixed on (j) makes the basis of the reassembling.

Place the rails @ x2

2)P1ace the stage baseplate@ on (D facing its rail groove to the rail groove of @ . Put the rails, rollers and retainer @ x2

oil.

Place the guide block @ e@) on CD facing its rail groove to the rail groove of(D. Fix the guide block @ to the upper plate Q by screwing the screws @ x J.

3)Make sure that no slack in the X direction is found at the both end of the moving range of the upper

plate(D on the base plate {]).

If any slack is found, release slightly the screws@ xJ to adjust the guide block @ (or @) that has been just reassembled by the procedure 2).

4)P1ace the whole stage assembly tilting on the work table soas the X rail groove of(D is on the

upperside.

Put @x2

5)Apply G202 oi! to the both rail grooves ofG) on which put @ x4, then place 0 on G)so as

one rail groove ofÜ faces to the groove of(D. Put@x 4

6)Put @ x2 on 8 rail groove applying G202 oil and place the latter to face the groove ofO. Then, fix@to@,@ screwing the screws@x4.

7)Fix the vemier scale @ and its seat@ to the stage base(D by the screws@ x2.

8)Fix the handle assembly to the guide block @ or @ and adjust the meshing of the pinion and the X rack @ releasing the screws @x 2 slightly.

1

J

- 10-