Updating and Reconfiguring AROS

ROTKP | int | 30 | Proportional PID | for rotation |

ROTKV | int | 200 | Differential PID | for rotation |

ROTKI | int | 0 | Integral PID for | rotation |

TRANSACC | int | 300 | Translational acceleration; mm/sec2 | |

TRANSDECEL | int | 300 | Translational deceleration; mm/sec2 | |

TRANSKP | int | 15 | Proportional PID | for translation |

TRANSKV | int | 450 | Differential PID | for translation |

TRANSKI | int | 4 | Integral PID for | translation |

JOYVELMAX | int | 1000 | Joydrive maximum | translation velocity |

JOYRVELMAX | int | 50 | Joydrive maximum | rotational velocity |

The Proportional PID (Kp) values control the responsiveness of your robot. Lower values make for a slower system; higher values make the robot "zippier", but can lead to overshoot and oscillation.

The Derivative PID (Kv) dampens oscillation and overshoot. Increasing values gives better control of oscillation and overshoot, but they also make the robot’s movements more sluggish.

The Integral PID (Ki) adjusts residual error in turning and velocity. Higher values make the robot correct increasingly smaller errors between its desired and actual angular position and speed.

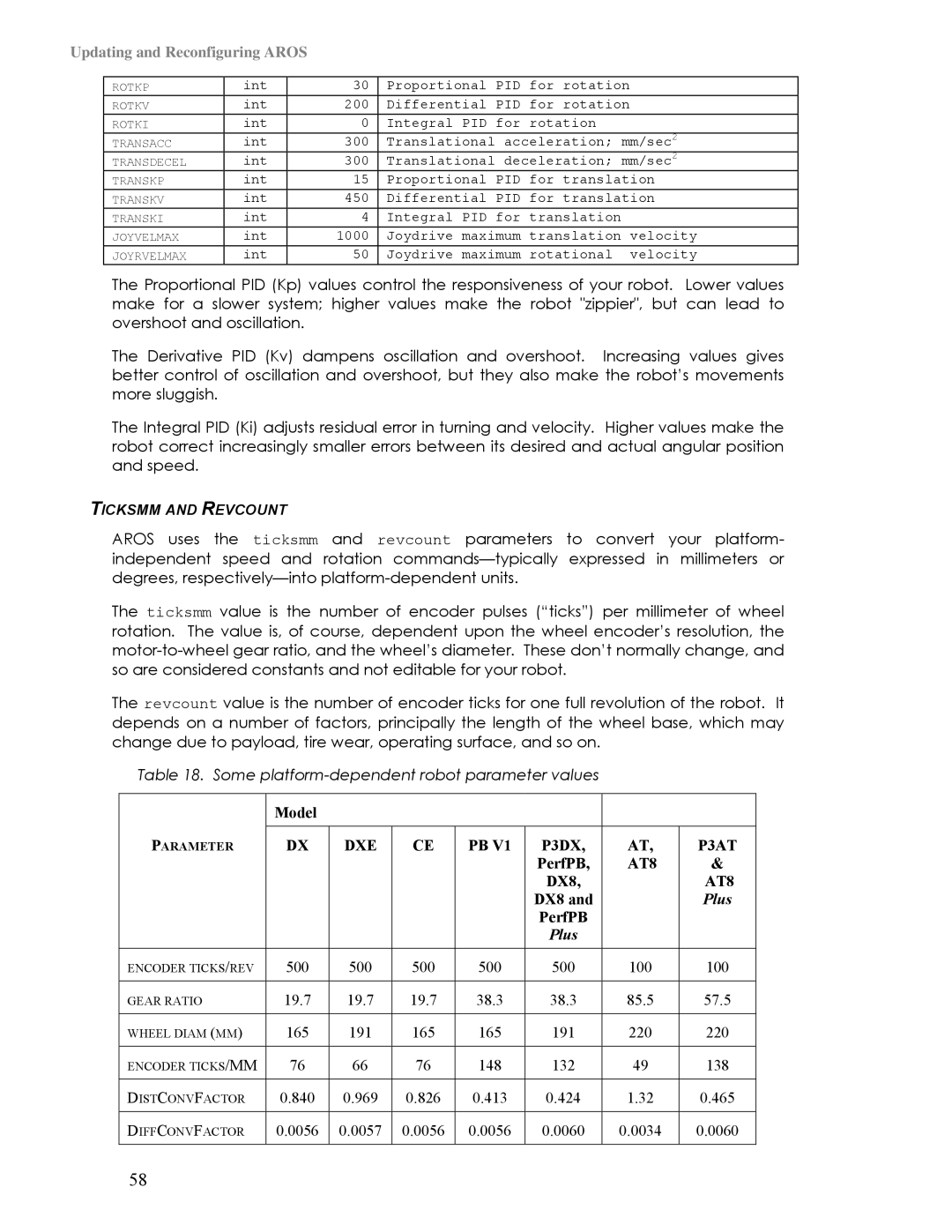

TICKSMM AND REVCOUNT

AROS uses the ticksmm and revcount parameters to convert your platform- independent speed and rotation

The ticksmm value is the number of encoder pulses (“ticks”) per millimeter of wheel rotation. The value is, of course, dependent upon the wheel encoder’s resolution, the

The revcount value is the number of encoder ticks for one full revolution of the robot. It depends on a number of factors, principally the length of the wheel base, which may change due to payload, tire wear, operating surface, and so on.

Table 18. Some

| Model |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PARAMETER | DX | DXE | CE | PB V1 | P3DX, | AT, | P3AT |

|

|

|

|

| PerfPB, | AT8 | & |

|

|

|

|

| DX8, |

| AT8 |

|

|

|

|

| DX8 and |

| Plus |

|

|

|

|

| PerfPB |

|

|

|

|

|

|

| Plus |

|

|

ENCODER TICKS/REV | 500 | 500 | 500 | 500 | 500 | 100 | 100 |

|

|

|

|

|

|

|

|

GEAR RATIO | 19.7 | 19.7 | 19.7 | 38.3 | 38.3 | 85.5 | 57.5 |

|

|

|

|

|

|

|

|

WHEEL DIAM (MM) | 165 | 191 | 165 | 165 | 191 | 220 | 220 |

|

|

|

|

|

|

|

|

ENCODER TICKS/MM | 76 | 66 | 76 | 148 | 132 | 49 | 138 |

|

|

|

|

|

|

|

|

DISTCONVFACTOR | 0.840 | 0.969 | 0.826 | 0.413 | 0.424 | 1.32 | 0.465 |

|

|

|

|

|

|

|

|

DIFFCONVFACTOR | 0.0056 | 0.0057 | 0.0056 | 0.0056 | 0.0060 | 0.0034 | 0.0060 |

|

|

|

|

|

|

|

|

58