ActivMedia Robotics Operating System

At the same time, AROS reports back to the client in the standard SIP the robot’s position and speed. Not all robots convert these values into

So when you tell the robot to move a certain number of millimeters forward, measure its actual travel with a meter tape and adjust ticksmm accordingly. Similarly, turn the robot and adjust revcount to achieve the correct heading.

Then, when you are satisfied that the robot moves and turns precisely, adjust the various parameter

Please see the next chapter for a detailed description of these

PID Controls

The AROS drive servers use a common

The AROS drive servers recalculate and adjust your robot’s trajectory and speed every five milliseconds based on feedback from the wheel encoders.

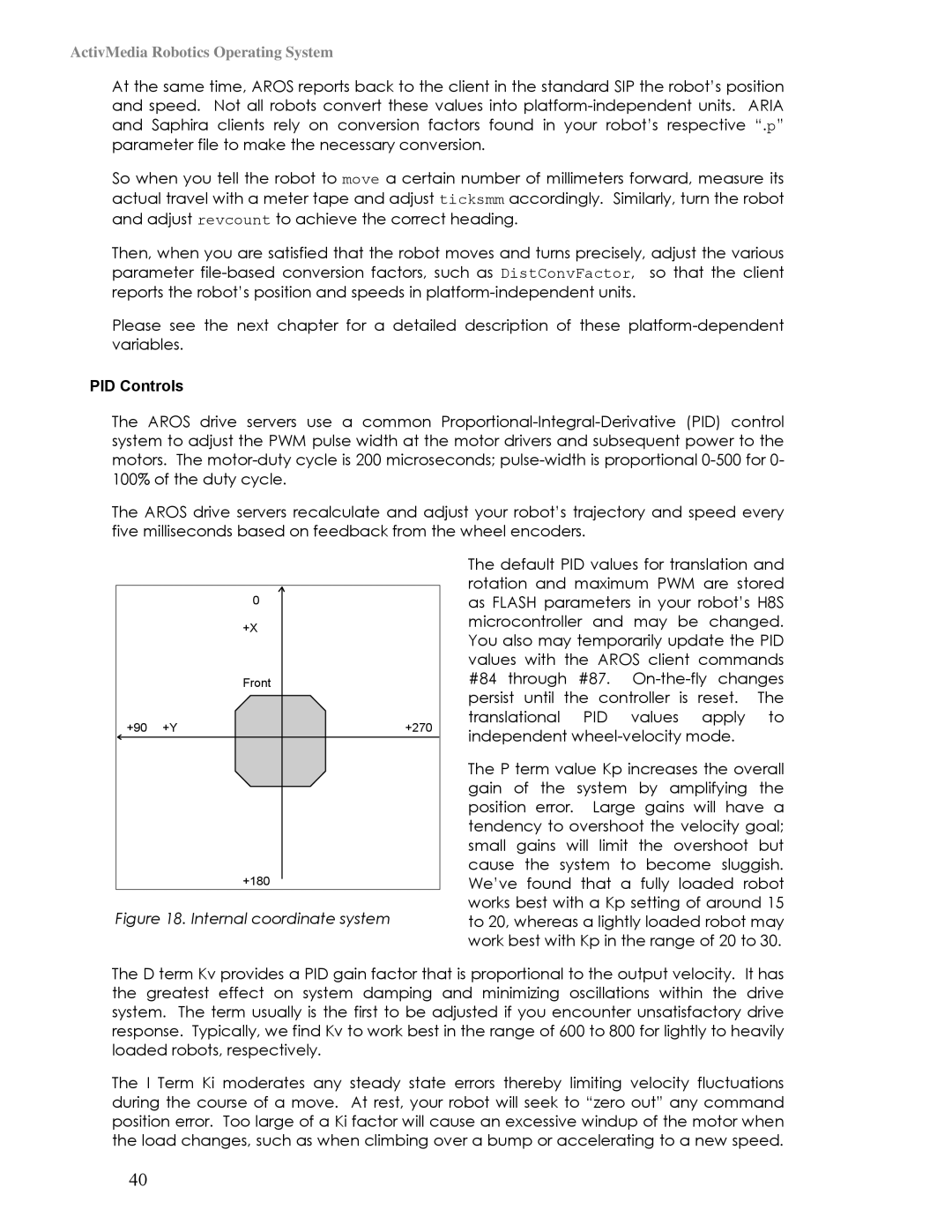

0

+X

Front

+90 +Y | +270 |

+180

Figure 18. Internal coordinate system

The default PID values for translation and rotation and maximum PWM are stored as FLASH parameters in your robot’s H8S microcontroller and may be changed. You also may temporarily update the PID values with the AROS client commands #84 through #87.

The P term value Kp increases the overall gain of the system by amplifying the position error. Large gains will have a tendency to overshoot the velocity goal; small gains will limit the overshoot but cause the system to become sluggish. We’ve found that a fully loaded robot works best with a Kp setting of around 15 to 20, whereas a lightly loaded robot may work best with Kp in the range of 20 to 30.

The D term Kv provides a PID gain factor that is proportional to the output velocity. It has the greatest effect on system damping and minimizing oscillations within the drive system. The term usually is the first to be adjusted if you encounter unsatisfactory drive response. Typically, we find Kv to work best in the range of 600 to 800 for lightly to heavily loaded robots, respectively.

The I Term Ki moderates any steady state errors thereby limiting velocity fluctuations during the course of a move. At rest, your robot will seek to “zero out” any command position error. Too large of a Ki factor will cause an excessive windup of the motor when the load changes, such as when climbing over a bump or accelerating to a new speed.

40