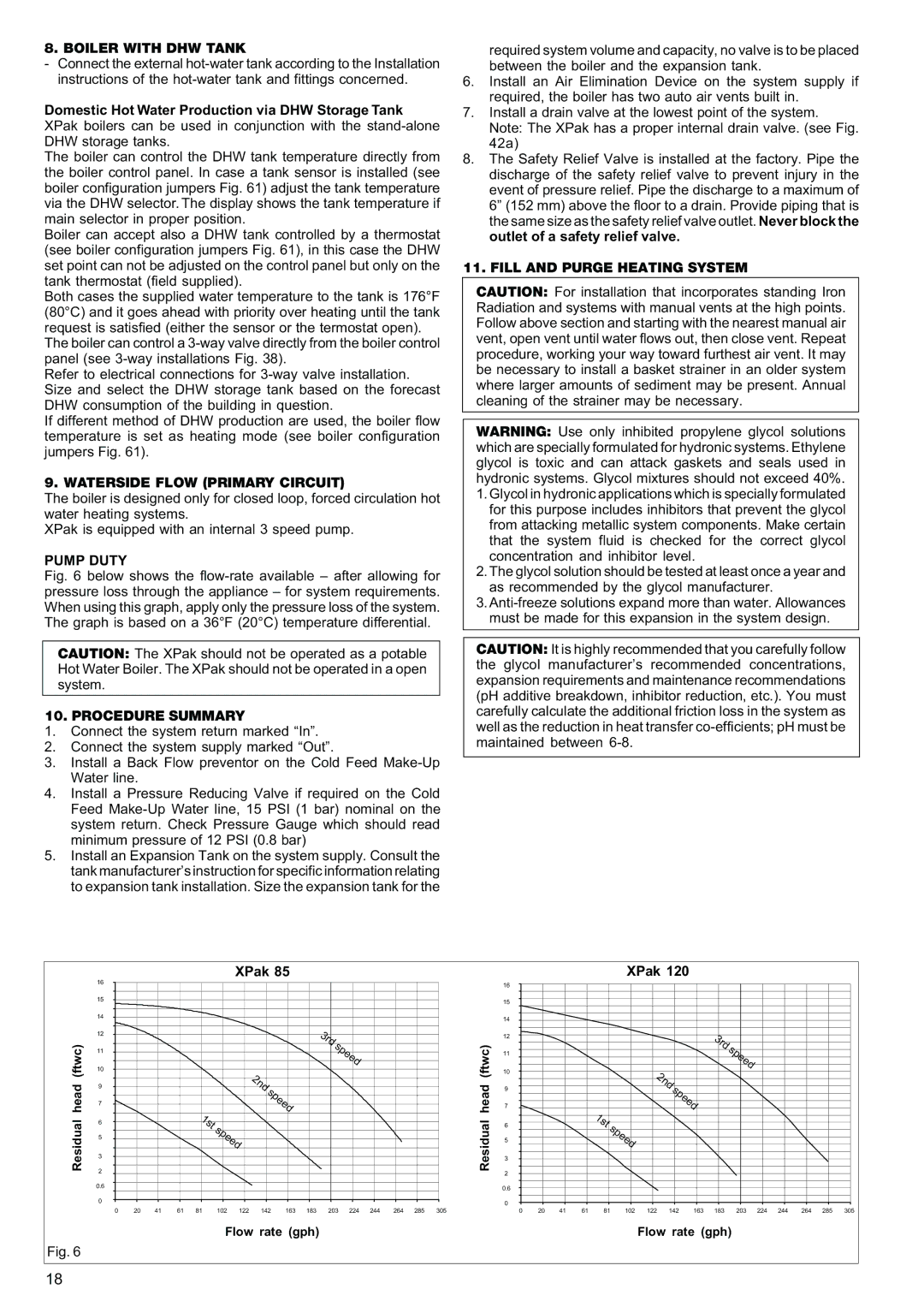

120, 85 specifications

The Raypak 120,85 is a prominent model in the realm of pool and spa heating solutions, designed to deliver unmatched efficiency and performance. Renowned for its robust features and innovative technologies, the Raypak 120,85 stands out as a reliable choice for homeowners seeking to maintain the perfect water temperature in their pools and spas.One of the primary characteristics of the Raypak 120,85 is its impressive heating capacity. With a total output of 120,000 BTUs, this heater quickly and efficiently warms up water, ensuring that users can enjoy comfortable swimming conditions regardless of the outdoor temperature. The 85 indicates its ability to deliver consistent performance even in cooler climates, making it an adaptable option for various geographical locations.

The Raypak 120,85 is equipped with a state-of-the-art, copper fin tube heat exchanger, which provides superior heat transfer efficiency. This technology enhances the heater's ability to warm water rapidly while maintaining energy efficiency. Additionally, the copper material is known for its durability and resistance to corrosion, ensuring a long lifespan for the heat exchanger.

Another key feature of the Raypak 120,85 is its electronic ignition system. This innovation eliminates the need for a standing pilot light, which not only saves energy but also enhances safety by reducing the risk of gas leaks associated with traditional ignition systems. The electronic ignition provides precise control, ensuring a reliable start each time.

The Raypak 120,85 also boasts a digital display control panel, allowing users to easily monitor and adjust the water temperature settings. This intuitive interface provides accurate readings and simplifies the operation, making it accessible for all users, regardless of their technical expertise.

Furthermore, this heater is designed with a compact footprint, making it suitable for a variety of installation spaces, whether it’s in a pool equipment area or near a spa. Its robust build quality and weather-resistant design ensure that it can withstand the elements, making it a durable and long-lasting investment.

In summary, the Raypak 120,85 combines advanced heating technology, robust construction, and user-friendly features. With its high BTU output, efficient heat exchanger, electronic ignition, and digital controls, it represents a top-tier option for anyone seeking reliable and effective heating solutions for pools and spas. Whether for leisure or relaxation, the Raypak 120,85 promises to deliver an optimal swimming experience, season after season.