Chapter 2 Installation | Series |

|

|

Unobstructed Flow Requirements

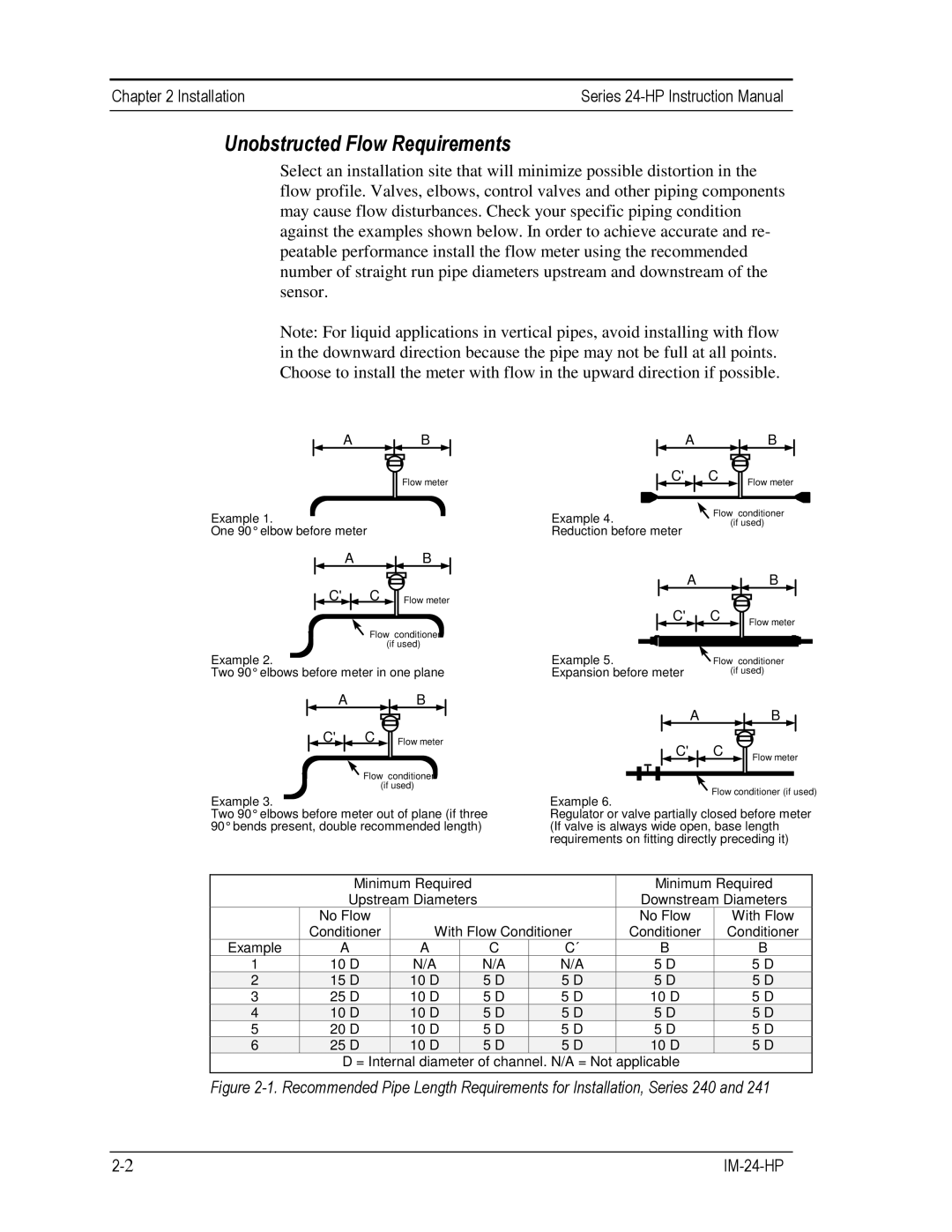

Select an installation site that will minimize possible distortion in the flow profile. Valves, elbows, control valves and other piping components may cause flow disturbances. Check your specific piping condition against the examples shown below. In order to achieve accurate and re- peatable performance install the flow meter using the recommended number of straight run pipe diameters upstream and downstream of the sensor.

Note: For liquid applications in vertical pipes, avoid installing with flow in the downward direction because the pipe may not be full at all points. Choose to install the meter with flow in the upward direction if possible.

A

B

A

B

Flow meter

Example 1.

One 90°elbow before meter

C' | C | Flow meter |

|

| |

Example 4. | Flow conditioner | |

| (if used) | |

Reduction before meter |

| |

|

| |

AB

C' |

|

| C | Flow meter | ||

| ||||||

|

|

|

|

|

| |

|

|

|

|

|

|

|

Flow conditioner (if used)

Example 2.

Two 90°elbows before meter in one plane

AB

C' | C | Flow meter |

|

|

Example 5. | Flow conditioner |

Expansion before meter | (if used) |

AB

C' |

|

| C | Flow meter | ||

| ||||||

|

|

|

|

|

| |

|

|

|

|

|

|

|

Flow conditioner (if used)

Example 3.

Two 90°elbows before meter out of plane (if three 90°bends present, double recommended length)

A |

| B |

C' | C | Flow meter |

|

|

Flow conditioner (if used)

Example 6.

Regulator or valve partially closed before meter (If valve is always wide open, base length requirements on fitting directly preceding it)

|

| Minimum Required |

|

| Minimum Required | ||||

|

| Upstream Diameters |

|

| Downstream Diameters | ||||

|

| No Flow |

|

|

|

| No Flow | With Flow | |

|

| Conditioner | With Flow Conditioner | Conditioner | Conditioner | ||||

| Example | A | A |

| C | C´ | B | B | |

| 1 | 10 D | N/A |

| N/A | N/A | 5 D | 5 D | |

| 2 | 15 D | 10 D |

| 5 D | 5 D | 5 D | 5 D | |

| 3 | 25 D | 10 D |

| 5 D | 5 D | 10 D | 5 D | |

| 4 | 10 D | 10 D |

| 5 D | 5 D | 5 D | 5 D | |

| 5 | 20 D | 10 D |

| 5 D | 5 D | 5 D | 5 D | |

| 6 | 25 D | 10 D |

| 5 D | 5 D | 10 D | 5 D | |

|

| D = Internal diameter of channel. N/A = Not applicable |

|

| |||||

|

| ||||||||

| Figure | ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||