Series | Chapter 2 Installation |

|

|

7.Tighten the packing gland nuts to stop leakage around the stem. Do not torque over 20

8.Slide the stem clamp back into position. Torque stem clamp bolts to 15

9.To separate the insertion tool from the flow meter, remove four socket head cap bolts securing the upper and lower retractor brackets. Remove the insertion tool.

Installation of Meters with Packing Gland Connection (No Insertion Tool)*

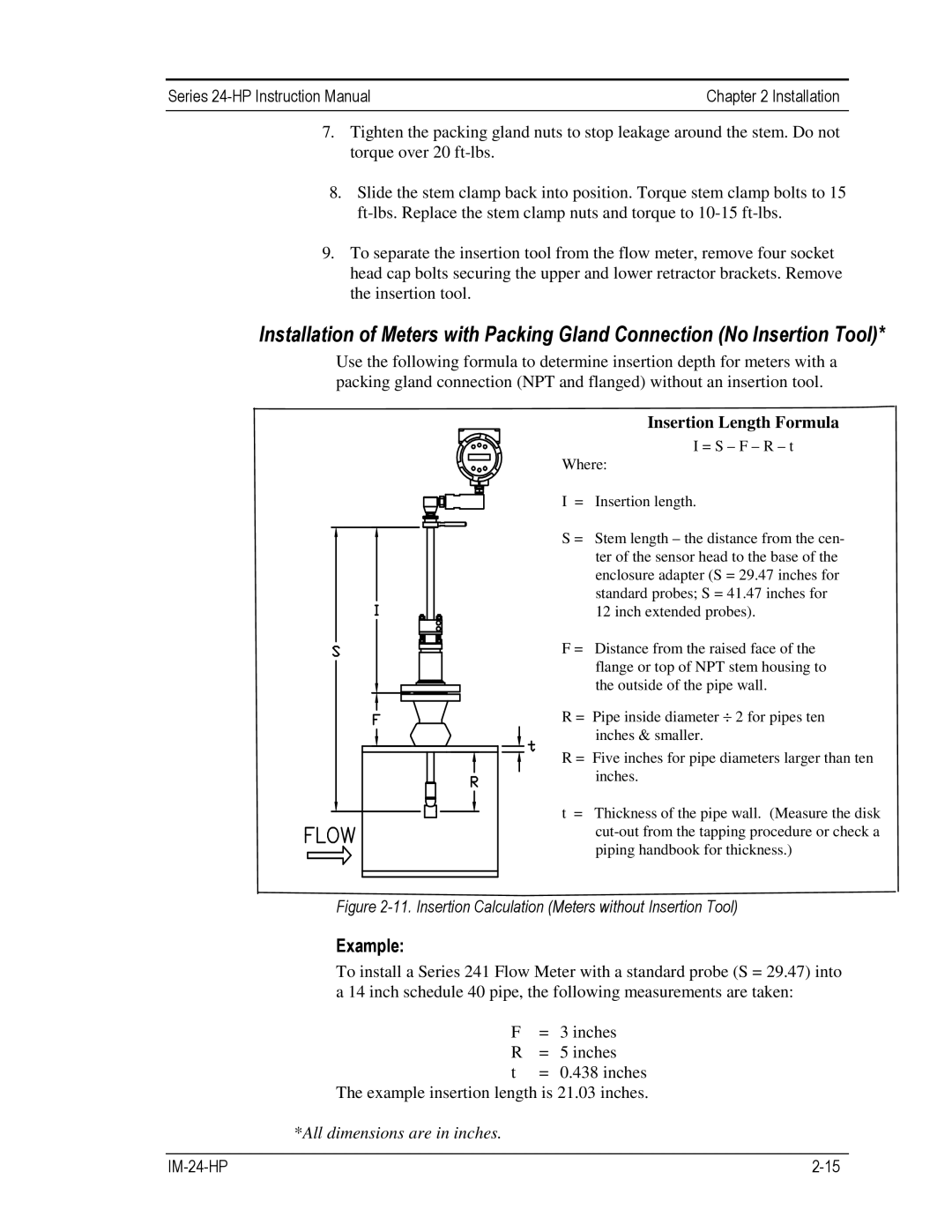

Use the following formula to determine insertion depth for meters with a packing gland connection (NPT and flanged) without an insertion tool.

Insertion Length Formula

I = S – F – R – t

Where:

I = Insertion length.

S = Stem length – the distance from the cen- ter of the sensor head to the base of the enclosure adapter (S = 29.47 inches for standard probes; S = 41.47 inches for 12 inch extended probes).

F = Distance from the raised face of the flange or top of NPT stem housing to the outside of the pipe wall.

R = Pipe inside diameter ⎟ 2 for pipes ten inches & smaller.

R = Five inches for pipe diameters larger than ten inches.

t = Thickness of the pipe wall. (Measure the disk

Figure 2-11. Insertion Calculation (Meters without Insertion Tool)

Example:

To install a Series 241 Flow Meter with a standard probe (S = 29.47) into a 14 inch schedule 40 pipe, the following measurements are taken:

F= 3 inches R = 5 inches

t = 0.438 inches

The example insertion length is 21.03 inches.

*All dimensions are in inches.