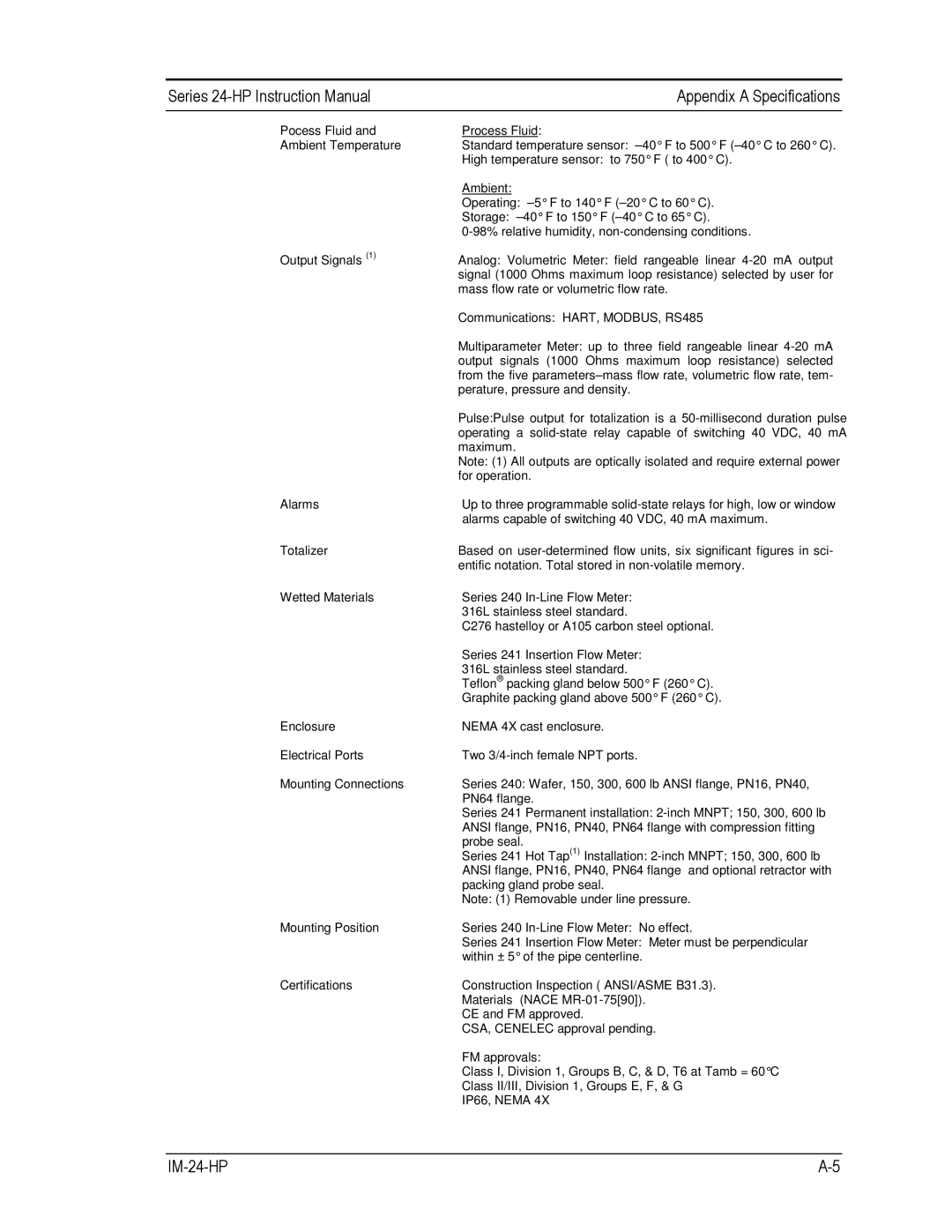

Series | Appendix A Specifications | |

|

|

|

Pocess Fluid and | Process Fluid: | |

Ambient Temperature | Standard temperature sensor: | |

| High temperature sensor: to 750°F ( to 400°C). | |

| Ambient: | |

| Operating: | |

| Storage: | |

| ||

Output Signals (1) | Analog: Volumetric Meter: field rangeable linear | |

| signal (1000 Ohms maximum loop resistance) selected by user for | |

| mass flow rate or volumetric flow rate. | |

| Communications: HART, MODBUS, RS485 | |

| Multiparameter Meter: up to three field rangeable linear | |

| output signals (1000 Ohms maximum loop resistance) selected | |

| from the five | |

| perature, pressure and density. | |

| Pulse:Pulse output for totalization is a | |

| operating a | |

| maximum. | |

| Note: (1) All outputs are optically isolated and require external power | |

| for operation. | |

Alarms | Up to three programmable | |

| alarms capable of switching 40 VDC, 40 mA maximum. | |

Totalizer | Based on | |

| entific notation. Total stored in | |

Wetted Materials | Series 240 | |

| 316L stainless steel standard. | |

| C276 hastelloy or A105 carbon steel optional. | |

| Series 241 Insertion Flow Meter: | |

| 316L stainless steel standard. | |

| Teflon® packing gland below 500°F (260°C). | |

| Graphite packing gland above 500°F (260°C). | |

Enclosure | NEMA 4X cast enclosure. | |

Electrical Ports | Two | |

Mounting Connections | Series 240: Wafer, 150, 300, 600 lb ANSI flange, PN16, PN40, | |

| PN64 flange. | |

| Series 241 Permanent installation: | |

| ANSI flange, PN16, PN40, PN64 flange with compression fitting | |

| probe seal. | |

| Series 241 Hot Tap(1) Installation: | |

| ANSI flange, PN16, PN40, PN64 flange and optional retractor with | |

| packing gland probe seal. | |

| Note: (1) Removable under line pressure. | |

Mounting Position | Series 240 | |

| Series 241 Insertion Flow Meter: Meter must be perpendicular | |

| within ± 5°of the pipe centerline. | |

Certifications | Construction Inspection ( ANSI/ASME B31.3). | |

| Materials (NACE | |

| CE and FM approved. | |

| CSA, CENELEC approval pending. | |

| FM approvals: | |

| Class I, Division 1, Groups B, C, & D, T6 at Tamb = 60°C | |

| Class II/III, Division 1, Groups E, F, & G | |

| IP66, NEMA 4X | |

|

|

|

| ||