Series | Chapter 2 Installation |

|

|

Series 240 In-Line Flow Meter Installation

Install the Series 240

The meter inside diameter is equal to the same size nominal pipe ID in schedule 80. For example, a 2” meter has an ID of 1.939” (2” schedule 80). Do not install the meter in a pipe with an inside diameter smaller than the inside diameter of the meter. For schedule 160 and higher pipe, a special meter is required. Consult the factory before pur- chasing the meter.

Series 240 Meters require

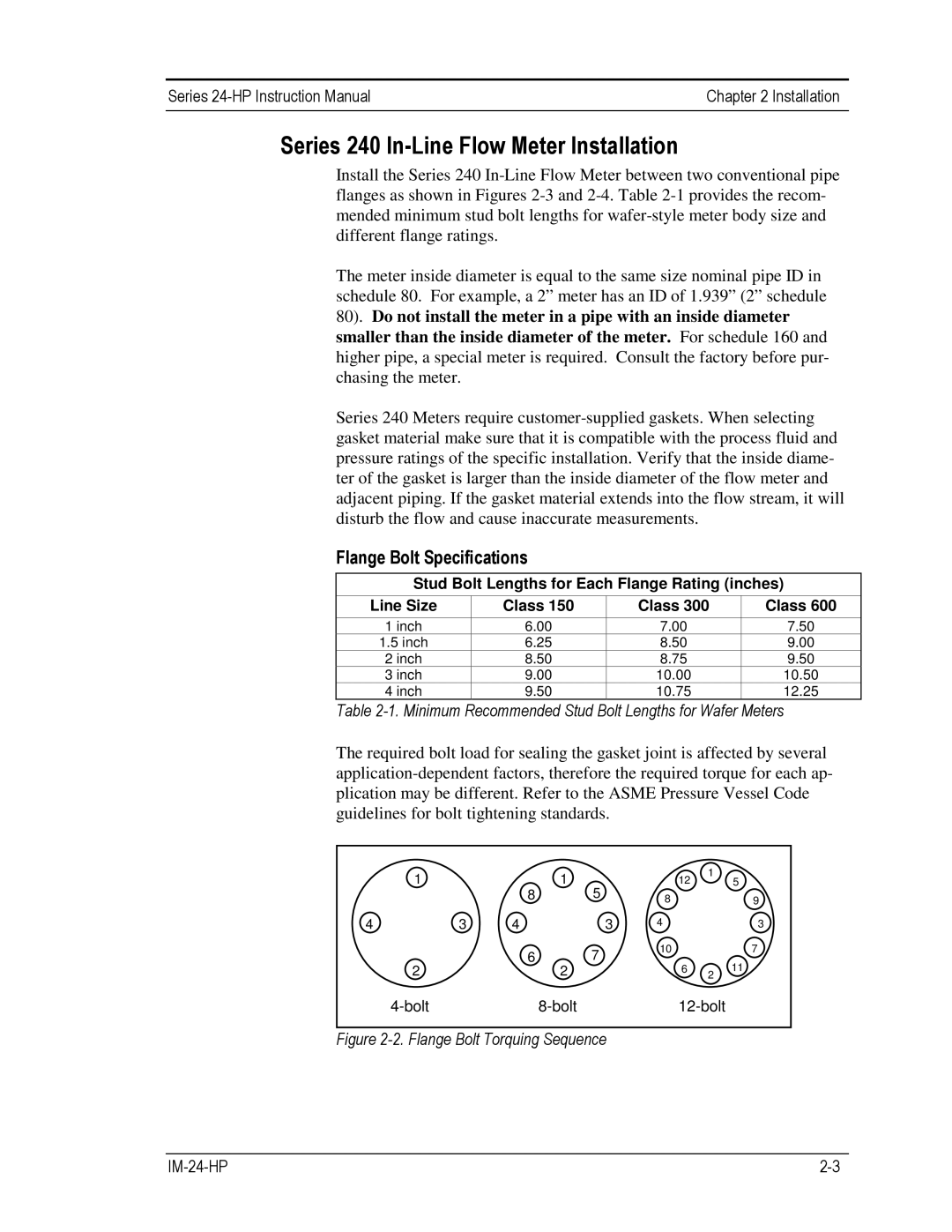

Flange Bolt Specifications

Stud Bolt Lengths for Each Flange Rating (inches)

Line Size | Class 150 | Class 300 |

1 inch | 6.00 | 7.00 |

1.5 inch | 6.25 | 8.50 |

2 inch | 8.50 | 8.75 |

3 inch | 9.00 | 10.00 |

4 inch | 9.50 | 10.75 |

Class 600

7.50

9.00

9.50

10.50

12.25

Table 2-1. Minimum Recommended Stud Bolt Lengths for Wafer Meters

The required bolt load for sealing the gasket joint is affected by several

| 1 |

| 1 |

| 12 | 1 | 5 |

|

|

|

| ||||

|

| 8 | 5 | 8 |

|

| 9 |

|

|

|

|

|

| ||

4 | 3 | 4 | 3 | 4 |

|

| 3 |

|

| 6 | 7 | 10 |

|

| 7 |

|

|

| 6 |

| 11 | ||

| 2 |

| 2 |

| 2 | ||

|

|

|

|

| |||

|

|

|

| ||||

Figure 2-2. Flange Bolt Torquing Sequence

|