9-8. EVACUATING

AIR PURGE

Evacuate the air in the connecting pipe and in the indoor unit using vacuum pump.

Do not use the refrigerant in the outdoor unit. For details, see the manual of vacuum pump.

9-8-1. Use a vacuum pump

Be sure to use a vacuum pump with

1.Connect the charge hose from the manifold valve to the service port of the gas side packed valve.

2.Connect the charge hose to the port of vacuum pump.

3.Open fully the low pressure side handle of the gauge manifold valve.

4.Operate the vacuum pump to start for evacuating. Perform evacuating for about 35 minutes if the piping length is total 30 meters for model SM560 and 50 meters for model SM800.

(assuming a pump capacity of 27 liters per minute.) Then confirm that the compound pressure gauge reading is

5.Close the low pressure side valve handle of gauge manifold.

6.Open fully the valve stem of the packed valves (both sides of Gas and Liquid).

7.Remove the charging hose from the service port.

8.Securely tighten the caps on the packed valves.

NOTE :

•Use the vacuum pump, vacuum pump adapters, and gauge manifold referring to the manuals attached to each tool before using them.

For the vacuum pump, check oil is filled up to the specified line of the oil gauge.

•While the air is purged, check again that the connecting port of charge hose, which has a projection to push the valve core, is firmly connected to the charge port.

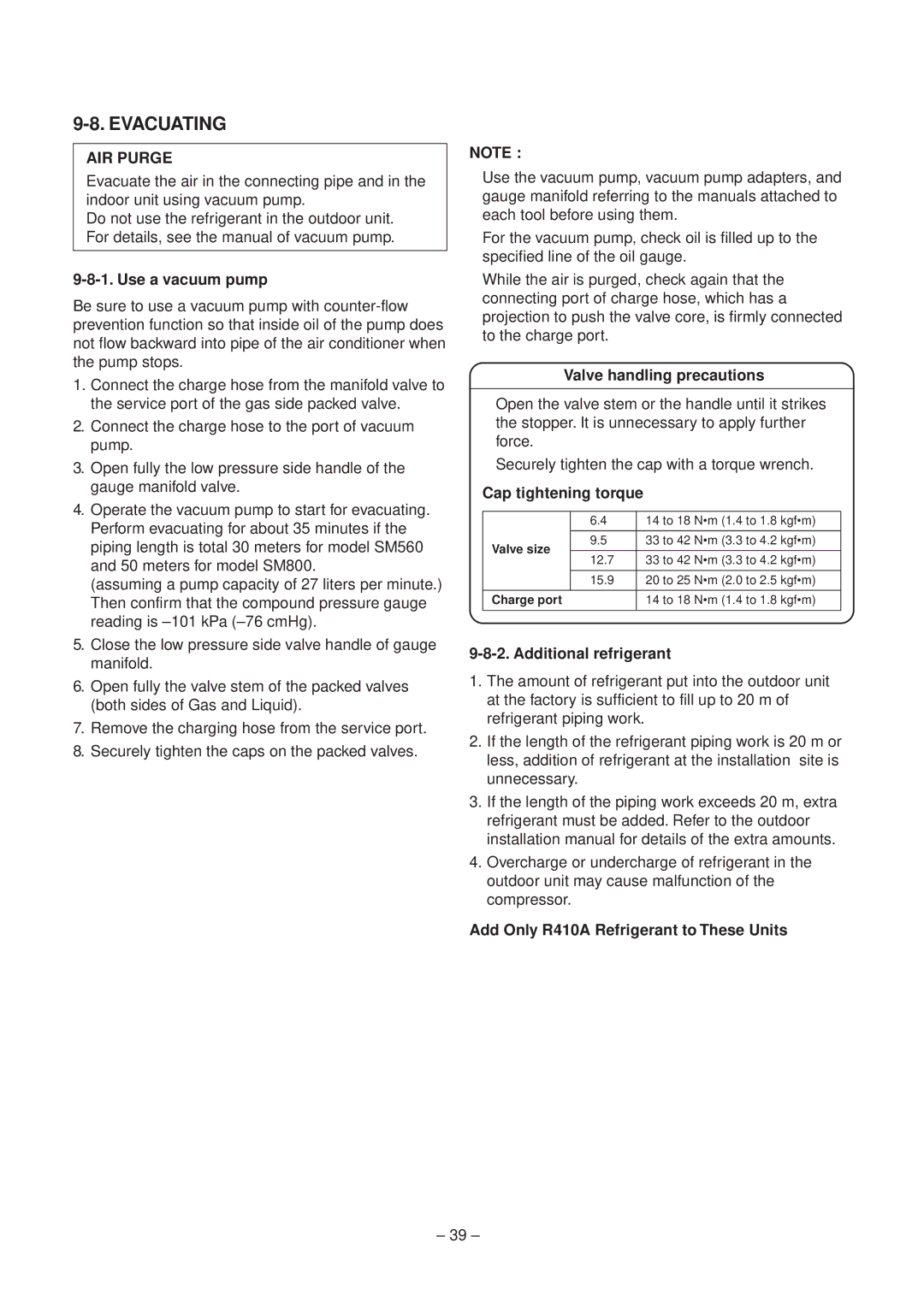

Valve handling precautions

•Open the valve stem or the handle until it strikes the stopper. It is unnecessary to apply further force.

•Securely tighten the cap with a torque wrench.

Cap tightening torque

| ∅6.4 | 14 to 18 N•m (1.4 to 1.8 kgf•m) | |

|

|

| |

Valve size | ∅9.5 | 33 to 42 N•m (3.3 to 4.2 kgf•m) | |

|

| ||

∅12.7 | 33 to 42 N•m (3.3 to 4.2 kgf•m) | ||

| |||

|

|

| |

| ∅15.9 | 20 to 25 N•m (2.0 to 2.5 kgf•m) | |

|

|

| |

Charge port |

| 14 to 18 N•m (1.4 to 1.8 kgf•m) | |

|

|

|

9-8-2. Additional refrigerant

1.The amount of refrigerant put into the outdoor unit at the factory is sufficient to fill up to 20 m of refrigerant piping work.

2.If the length of the refrigerant piping work is 20 m or less, addition of refrigerant at the installation site is unnecessary.

3.If the length of the piping work exceeds 20 m, extra refrigerant must be added. Refer to the outdoor installation manual for details of the extra amounts.

4.Overcharge or undercharge of refrigerant in the outdoor unit may cause malfunction of the compressor.

Add Only R410A Refrigerant to These Units

– 39 –