AIR-CONDITIONER

Contents

Indoor Unit

Specifications

Current

Operation characteristic curve Cooling Heating

RAV-SM560AT-E RAV-SM800AT-E

Outdoor Unit

Construction Views

Outdoor Unit RAV-SM560AT-E

Outdoor Unit RAV-SM800AT-E

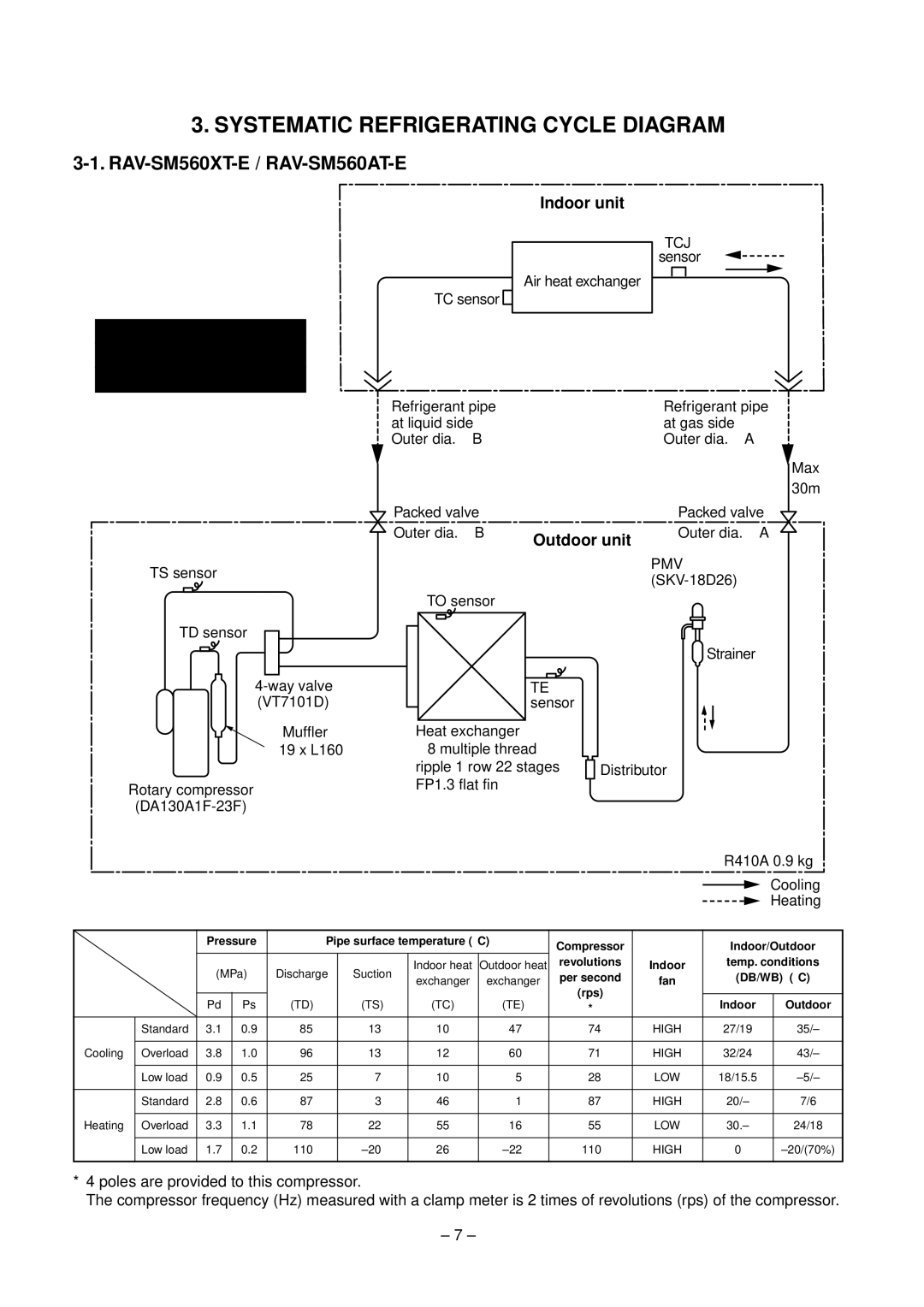

RAV-SM560XT-E / RAV-SM560AT-E

Systematic Refrigerating Cycle Diagram

Indoor unit

RAV-SM800XT-E / RAV-SM800AT-E

Color Identification

Wiring Diagram

L N

Board

Parts name Type Specifications

Specification of Electrical Parts

Refrigerant Piping Installation

Safety During Installation/Servicing

Refrigerant R410A

Piping materials and joints used

1 Thicknesses of annealed copper pipes Thickness mm

Outer diameter mm R410A R22

Processing of piping materials

Width

Clutch type Wing nut type

·m kgf·m

·m kgf·cm

Tools

Required tools

General tools Conventional tools can be used

Recharging of Refrigerant

1 Configuration of refrigerant charging

Brazing of Pipes

Types of flux Noncorrosive flux

Characteristics required for flux

Activated flux

Filler Flux

Operation

Control Block Diagram

Operation mode selection

When power supply is reset

Air volume control

Operation Description

1 Cold draft preventing control

Cool air discharge preventive control

High-temp release control

Freeze preventive control Low temperature release

Louver control

Filter sign display

Auto Restart Function

How to set auto restart function

Operation

Motions

Power failure during timer operation

How to cancel auto restart function

How to turn off filter check lamp

Filter Check Lamp

Installation Diagram of Indoor and Outdoor Units

Installation Procedure

Under Ceiling Installation

Console Installation

To Disconnect the Appliance from Main Power Supply

Precautions for Safety

Page

Accessory parts and Parts to be procured locally

Accessory parts

Parts to be procured locally

Avoid installing in the following places

Selection of Installation Place

Remote controller

Installation Place

Remote controller usage

Before Installation Remove the Air inlet grille

Install the Suspension bolts

Install the indoor unit

Condition for Installation

Piping and Drain Hose Installation

Connect the Flexible pipe 5 to the large pipe Gas side

Cutting a hole and mounting the Installation plate

Unit must not decline more than 15 mm in either

Axis

Drainage

Drain Piping Work

Refrigerant Piping

Tightening connection

Evacuating

Heat insulation

For RAV-SM560AT-E model

Electrical Work

Final Installation Checks

LED indication and code checking

Environment

Summary of Troubleshooting

Troubleshooting

Before troubleshooting

Troubleshooting procedure

How to use remote control in service mode

Self-Diagnosis by Remote Control Check Code

Judgement and action

No display in the setting at shipment

Operation

YES

Troubleshooting for Each Check Code 1A error

Error

1C error* Except RAV-SM560AT-E

1D error

1E error

1F error

Connector normal?

Caracteristics-3

TA sensor TC, TCJ sensor Caracteristics-1 Caracteristics-2

20 TE, TO, TS sensor

TD sensor Caracteristics-4

Inspection procedure

Compressor does not operate

Primary check

Cooling and heating model

Are all of compressor cords normal?

How to install the Air inlet grille

Detachments

Remove the Panel arms from the Front panel

Open 3 Cap screws and remove the screws

How to remove the Drain pan

Refrigeration How to remove the Refrigeration assembly

Assembly Pan assembly

Part name Procedures Remarks

How to remove the Multiblade fan

Fan motor

Detachment

No. Part name Procedure Remarks

Procedure Remarks

Requirement

Connection with the power terminal

Part name Procedure Remarks

‡ Compressor Perform works of items 1 ‚, ƒ, „, …

Fan guard

Remove the upper cabinet

Discharge port cabinet for the heat ex

Part name

Requirement

… Control P.C Remove the inverter box from P.C. board base

Loosen the flange nut by turning clock

† Compressor Perform works of items , ‚, ƒ, „,

Ø4 x 10L , 2 pcs. per one reactor

Product

Indoor Unit E-Parts Assy

Exploded Views and Parts List

Air Inlet Grille

Inverter

21,22 16,17

702 TE Sensor TS Sensor To Sensor TD Sensor 701 705 703 704

Outdoor Unit Inverter Assy, RAV-SM560AT-E

Outdoor Unit Inverter Assy, RAV-SM800AT-E

Inverter BOX