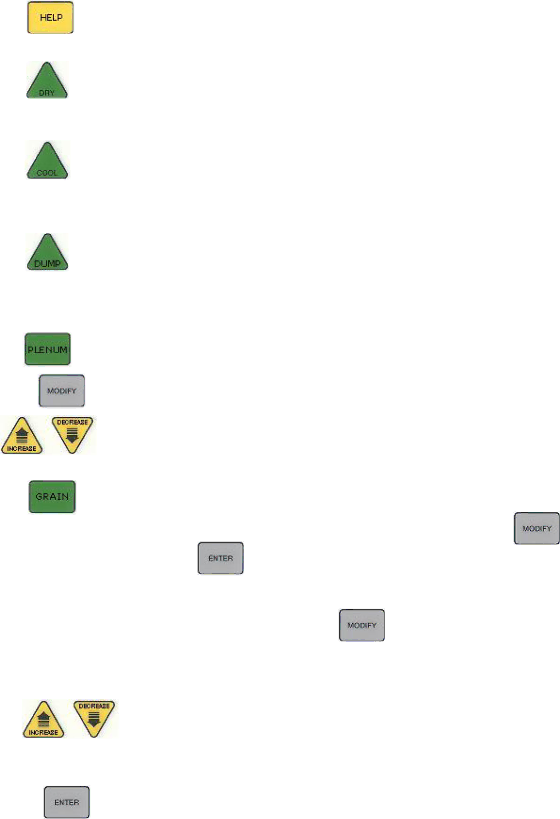

HELP BUTTON

T h e | button currently has no function. |

DRY BUTTON | |

T h e | button is used to change the Dry timer settings when you operate your dryer in the Batch |

mode. This button has no effect in the continous drying mode. Please refer to the Staged Batch section.

COOL BUTTON

Th ebutton is used to change the Cool timer settings when you operate your dryer in the Batch

mode. This button has no effect in the continous drying mode. Please refer to the Staged Batch section for Batch operation.

UNLOAD BUTTON

T h e button is used to change the Unload timer settings when you operate your dryer in the

Batch mode. This button has no effect in the continous drying mode. Please refer to the Staged Batch section for Batch operation.

PLENUM BUTTON

The | button allows you to view the plenum temperature of all the burners on your dryer. Press |

ing the | button allows you to change the plenum set point of the burner being viewed. Press |

to advance to the next screen (burner) or to accept any changes you may have made.

GRAIN BUTTON

T h e | button allows you to view or modify the moisture control (grain temperature) set point which | ||

determines the final moisture content of the grain being discharged from the dryer. Press the | |||

button to make any changes. Press | to advance to the next screen or to accept any changes you may | ||

have made. |

|

|

|

MODIFY BUTTON |

|

| |

When viewing a screen with settings that can be changed, the | button will allow you to edit the | ||

values on this screen. Otherwise this button will have no function available. | |||

INCREASE and DECREASE BUTTONS |

|

| |

The | are used when you are editing temperature, time values or for scrolling up and | ||

down the different screen selections. |

|

| |

ENTER BUTTON |

|

| |

Use the | button to accept any changes you may have made to timer, delay or setup screens. It | ||

is also used to advance to the next screen.

26 |

|