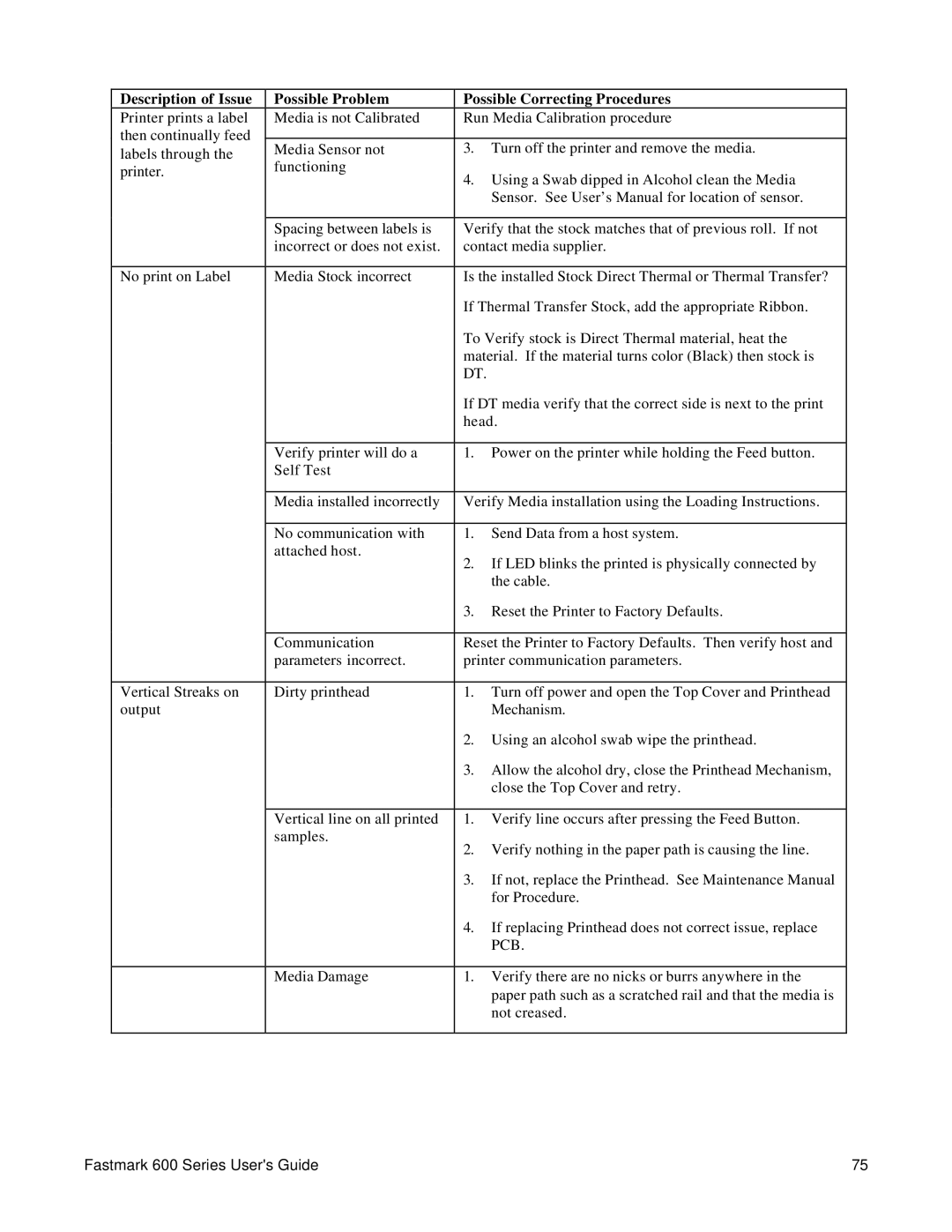

Description of Issue | Possible Problem | Possible Correcting Procedures | ||

Printer prints a label | Media is not Calibrated | Run Media Calibration procedure | ||

then continually feed |

|

|

| |

Media Sensor not | 3. | Turn off the printer and remove the media. | ||

labels through the | ||||

functioning |

|

| ||

printer. | 4. | Using a Swab dipped in Alcohol clean the Media | ||

| ||||

|

| |||

|

|

| Sensor. See User’s Manual for location of sensor. | |

|

|

| ||

| Spacing between labels is | Verify that the stock matches that of previous roll. If not | ||

| incorrect or does not exist. | contact media supplier. | ||

|

|

| ||

No print on Label | Media Stock incorrect | Is the installed Stock Direct Thermal or Thermal Transfer? | ||

|

| If Thermal Transfer Stock, add the appropriate Ribbon. | ||

|

| To Verify stock is Direct Thermal material, heat the | ||

|

| material. If the material turns color (Black) then stock is | ||

|

| DT. |

| |

|

| If DT media verify that the correct side is next to the print | ||

|

| head. | ||

|

|

|

| |

| Verify printer will do a | 1. | Power on the printer while holding the Feed button. | |

| Self Test |

|

| |

|

|

| ||

| Media installed incorrectly | Verify Media installation using the Loading Instructions. | ||

|

|

|

| |

| No communication with | 1. | Send Data from a host system. | |

| attached host. | 2. | If LED blinks the printed is physically connected by | |

|

| |||

|

|

| the cable. | |

|

| 3. | Reset the Printer to Factory Defaults. | |

|

|

| ||

| Communication | Reset the Printer to Factory Defaults. Then verify host and | ||

| parameters incorrect. | printer communication parameters. | ||

|

|

|

| |

Vertical Streaks on | Dirty printhead | 1. | Turn off power and open the Top Cover and Printhead | |

output |

|

| Mechanism. | |

|

| 2. | Using an alcohol swab wipe the printhead. | |

|

| 3. | Allow the alcohol dry, close the Printhead Mechanism, | |

|

|

| close the Top Cover and retry. | |

|

|

|

| |

| Vertical line on all printed | 1. | Verify line occurs after pressing the Feed Button. | |

| samples. | 2. | Verify nothing in the paper path is causing the line. | |

|

| |||

|

| 3. | If not, replace the Printhead. See Maintenance Manual | |

|

|

| for Procedure. | |

|

| 4. | If replacing Printhead does not correct issue, replace | |

|

|

| PCB. | |

|

|

|

| |

| Media Damage | 1. | Verify there are no nicks or burrs anywhere in the | |

|

|

| paper path such as a scratched rail and that the media is | |

|

|

| not creased. | |

|

|

|

| |

Fastmark 600 Series User's Guide | 75 |