Cleaning the Platen Roller

It is recommended that the platen roller should be cleaned when:

∙Excessive dusty condition exists.

∙Following a media jam where the adhesive comes in contact with it.

∙Because of the squeezing process of feeding the media the roller can become sticky from the adhesive being pressed out from behind the label.

1.Turn off the printer and open the top cover.

2.Lift the print head module to the vertical position.

3.Rub the full length of the platen available with a piece of cotton, which has been moistened with Isopropyl Alcohol.

4.Manually rotate the platen and repeat step 3 until the entire platen has been cleaned.

Cleaning the paper sensor

It is recommended that the Paper Sensor be cleaned regularly if exposed to a dusty environment. This will prevent false paper OUT or paper IN conditions.

1.Turn off the printer and open the top cover.

2.Remove paper dust by blowing using compressed air or vacuuming.

3.Clean the two Paper Sensor LED's with cotton stick, which has been moistened with Isopropyl Alcohol.

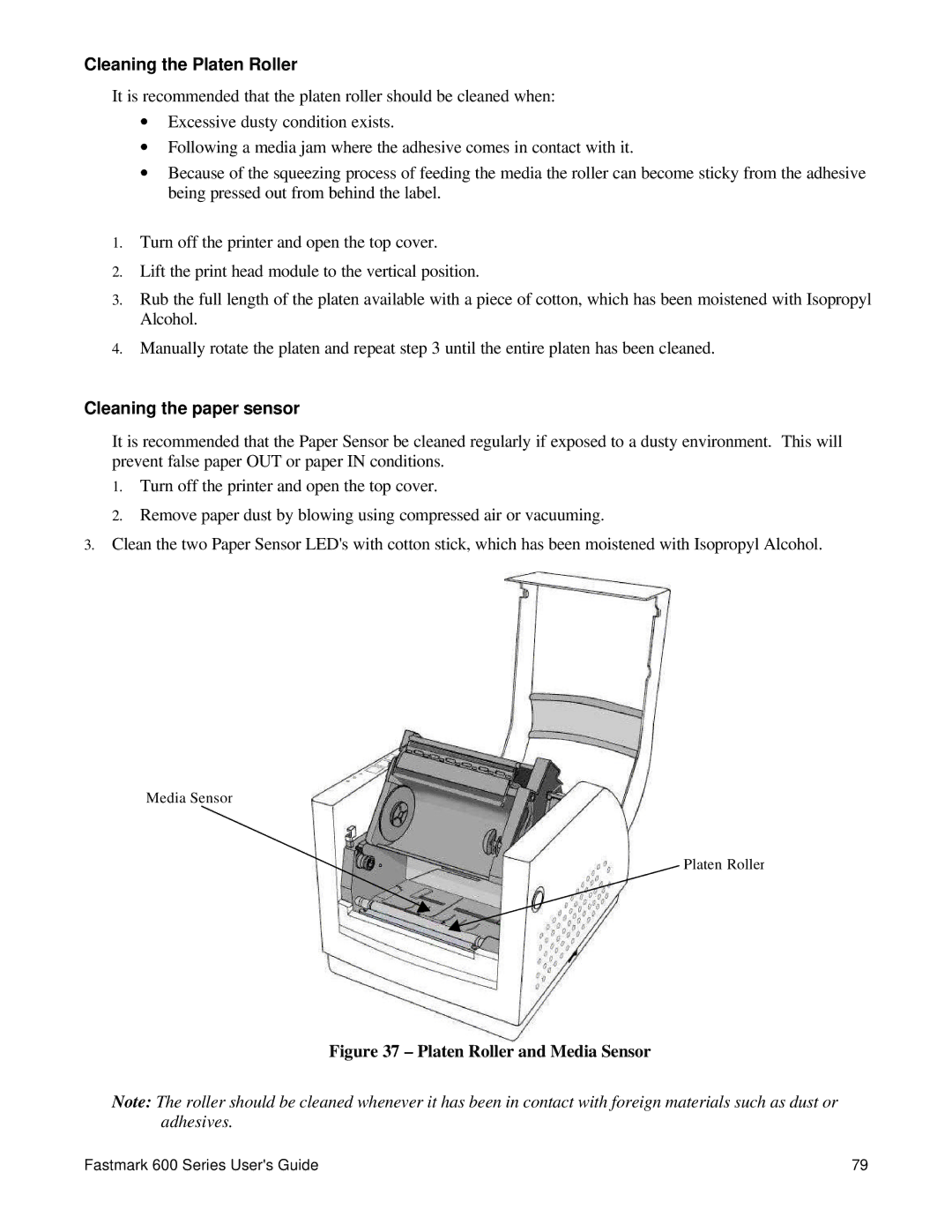

Media Sensor

Platen Roller

Figure 37 – Platen Roller and Media Sensor

Note: The roller should be cleaned whenever it has been in contact with foreign materials such as dust or adhesives.

Fastmark 600 Series User's Guide | 79 |