Applicable Models: EC-1200 EC-1600 EC-3600 EC-3700

No Display of Cadence (The cadence remains at zero (0) and does not count when the pedal is rotated.) |

|

|

| ||

| Check Method of Causes | Repair Method | Explanation Figures |

|

|

[1] Checking the Control Unit |

|

|

|

| |

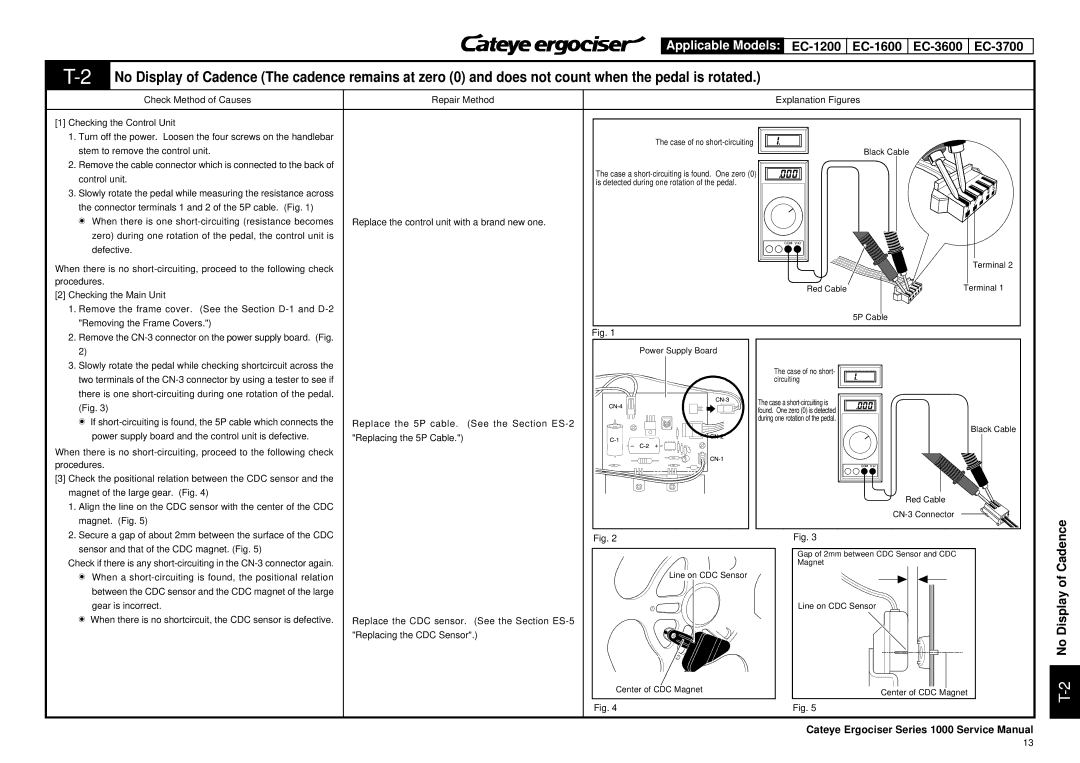

1. Turn off the power. Loosen the four screws on the handlebar | The case of no |

|

|

| |

stem to remove the control unit. |

|

|

| ||

|

| Black Cable |

| ||

2. Remove the cable connector which is connected to the back of | The case a |

|

|

| |

control unit. |

|

|

| ||

is detected during one rotation of the pedal. |

|

|

| ||

|

|

|

| 5 | |

3. Slowly rotate the pedal while measuring the resistance across |

|

| 4 | ||

|

|

| |||

|

|

|

| 3 |

|

the connector terminals 1 and 2 of the 5P cable. (Fig. 1) |

|

| 2 |

| |

|

| 1 |

| ||

t | When there is one | Replace the control unit with a brand new one. |

|

|

|

| zero) during one rotation of the pedal, the control unit is |

|

|

|

|

| defective. |

|

|

|

|

When there is no |

|

| Terminal 2 | ||

|

|

|

| ||

procedures. |

| Red Cable | Terminal 1 | ||

[2] Checking the Main Unit |

| ||||

|

|

|

| ||

1. Remove the frame cover. (See the Section |

|

|

|

| |

"Removing the Frame Covers.") |

|

| 5P Cable |

| Fig. 1 |

| |

2. Remove the |

|

| |

|

|

| |

2) |

|

| Power Supply Board |

3. Slowly rotate the pedal while checking shortcircuit across the |

|

| The case of no short- |

two terminals of the |

|

| |

|

| circuiting | |

there is one |

|

| The case a |

(Fig. 3) |

|

| |

|

| found. One zero (0) is detected | |

t If | Replace the 5P cable. | (See the Section | during one rotation of the pedal. |

Black Cable | |||

power supply board and the control unit is defective. | "Replacing the 5P Cable.") |

|

|

When there is no |

|

|

|

procedures. |

|

|

|

[3] Check the positional relation between the CDC sensor and the |

|

|

|

magnet of the large gear. (Fig. 4) |

|

| Red Cable |

1. Align the line on the CDC sensor with the center of the CDC |

|

| |

|

| ||

magnet. (Fig. 5) |

|

| |

|

|

| |

2. Secure a gap of about 2mm between the surface of the CDC |

| Fig. 2 | Fig. 3 |

sensor and that of the CDC magnet. (Fig. 5) |

|

| Gap of 2mm between CDC Sensor and CDC |

Check if there is any |

|

| |

|

| Magnet | |

t When a |

|

| Line on CDC Sensor |

|

|

| |

between the CDC sensor and the CDC magnet of the large |

|

|

|

gear is incorrect. |

|

| Line on CDC Sensor |

t When there is no shortcircuit, the CDC sensor is defective. | Replace the CDC sensor. | (See the Section |

|

| "Replacing the CDC Sensor".) |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ce | nter of CDC Mag | net | Center of CDC Magnet | |||||||

|

|

|

| |||||||

Fig. 4 | Fig. 5 | |||||||||

Cateye Ergociser Series 1000 Service Manual

T-2 No Display of Cadence

13