Applicable Models: EC-1200

MS-1 Replacing the Workload Unit (w/o Flywheel) (3)

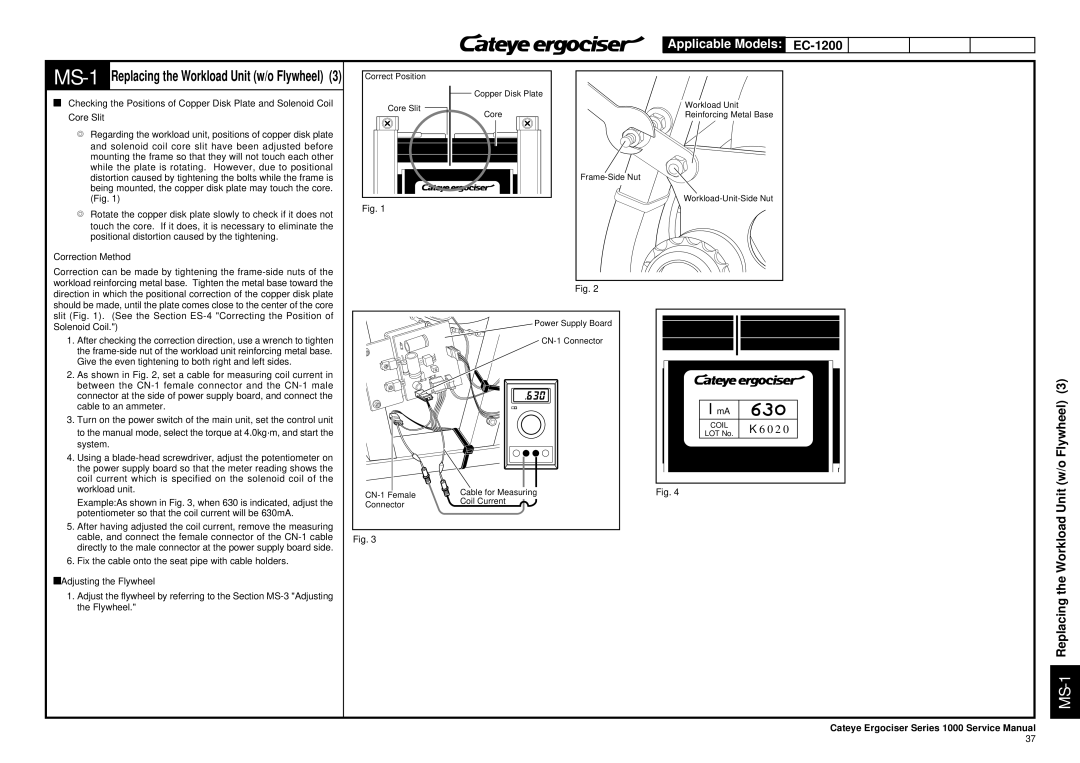

àChecking the Positions of Copper Disk Plate and Solenoid Coil Core Slit

TRegarding the workload unit, positions of copper disk plate and solenoid coil core slit have been adjusted before mounting the frame so that they will not touch each other while the plate is rotating. However, due to positional distortion caused by tightening the bolts while the frame is being mounted, the copper disk plate may touch the core. (Fig. 1)

TRotate the copper disk plate slowly to check if it does not touch the core. If it does, it is necessary to eliminate the positional distortion caused by the tightening.

Correction Method

Correction can be made by tightening the

Correct Position

Copper Disk Plate

Core Slit

Core |

Fig. 1

Workload Unit |

Reinforcing Metal Base |

Fig. 2

slit (Fig. 1). (See the Section

1.After checking the correction direction, use a wrench to tighten the

2.As shown in Fig. 2, set a cable for measuring coil current in between the

3.Turn on the power switch of the main unit, set the control unit to the manual mode, select the torque at 4.0kg·m, and start the system.

4.Using a

Example:As shown in Fig. 3, when 630 is indicated, adjust the potentiometer so that the coil current will be 630mA.

5.After having adjusted the coil current, remove the measuring cable, and connect the female connector of the

6.Fix the cable onto the seat pipe with cable holders.

àAdjusting the Flywheel

1.Adjust the flywheel by referring to the Section

| Power Supply Board | |

| ||

Cable for Measuring | ||

Coil Current | ||

Connector | ||

|

Fig. 3

I mA |

| |

COIL | K 6 0 2 0 | |

LOT No. | ||

|

Fig. 4

MS-1 Replacing the Workload Unit (w/o Flywheel) (3)

Cateye Ergociser Series 1000 Service Manual

37