Applicable Models: EC-1200

MS-1 Replacing the Workload Unit (w/o Flywheel) (2)

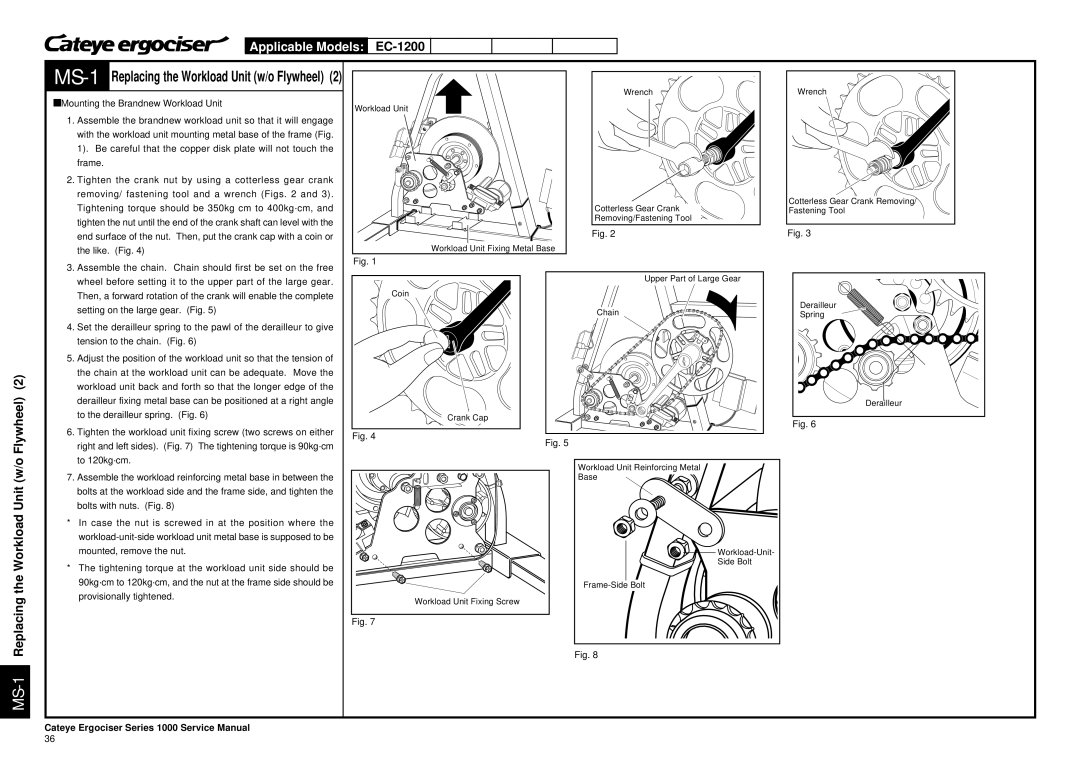

àMounting the Brandnew Workload Unit

1. Assemble the brandnew workload unit so that it will engage |

with the workload unit mounting metal base of the frame (Fig. |

1). Be careful that the copper disk plate will not touch the |

frame. |

2. Tighten the crank nut by using a cotterless gear crank |

removing/ fastening tool and a wrench (Figs. 2 and 3). |

Tightening torque should be 350kg cm to 400kg·cm, and |

tighten the nut until the end of the crank shaft can level with the |

end surface of the nut. Then, put the crank cap with a coin or |

the like. (Fig. 4) |

Workload Unit

Workload Unit Fixing Metal Base

Wrench

Cotterless Gear Crank Removing/Fastening Tool

Fig. 2

Wrench

Cotterless Gear Crank Removing/ Fastening Tool

Fig. 3

the Workload Unit (w/o Flywheel) (2)

3. | Assemble the chain. Chain should first be set on the free |

| wheel before setting it to the upper part of the large gear. |

| Then, a forward rotation of the crank will enable the complete |

| setting on the large gear. (Fig. 5) |

4. | Set the derailleur spring to the pawl of the derailleur to give |

| tension to the chain. (Fig. 6) |

5. | Adjust the position of the workload unit so that the tension of |

| the chain at the workload unit can be adequate. Move the |

| workload unit back and forth so that the longer edge of the |

| derailleur fixing metal base can be positioned at a right angle |

| to the derailleur spring. (Fig. 6) |

6. | Tighten the workload unit fixing screw (two screws on either |

| right and left sides). (Fig. 7) The tightening torque is 90kg·cm |

| to 120kg·cm. |

7. | Assemble the workload reinforcing metal base in between the |

| bolts at the workload side and the frame side, and tighten the |

| bolts with nuts. (Fig. 8) |

*In case the nut is screwed in at the position where the

*The tightening torque at the workload unit side should be 90kg·cm to 120kg·cm, and the nut at the frame side should be provisionally tightened.

Fig. 1

Coin

Crank Cap

Fig. 4

Workload Unit Fixing Screw

Upper Part of Large Gear

Chain

Fig. 5

Workload Unit Reinforcing Metal

Base

![]()

![]()

Side Bolt

Derailleur

Spring

Derailleur

Fig. 6

Fig. 7

Fig. 8

Cateye Ergociser Series 1000 Service Manual

36