Extended System Commands

computer via the serial port, contains all parameters controlled by the <STX>Kc command, and may be used for restoring the printer’s configuration or for configuring other printers. Media sensing scaling values, TOF Bias, etc. may not be effective on other printers of the same type due to hardware tolerances.

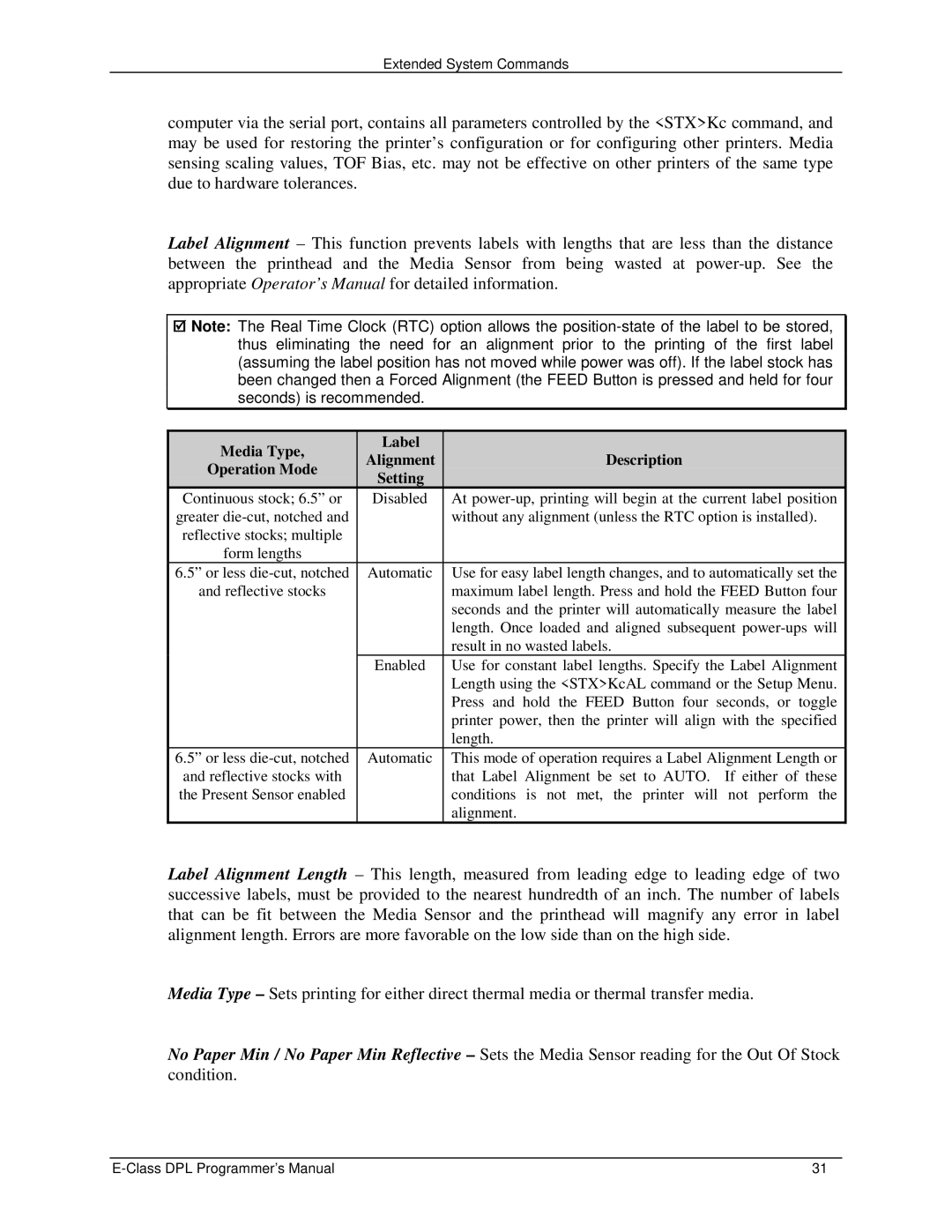

Label Alignment – This function prevents labels with lengths that are less than the distance between the printhead and the Media Sensor from being wasted at

Note: The Real Time Clock (RTC) option allows the

Media Type, | Label |

| |

| |||

Alignment | Description | ||

Operation Mode | |||

Setting |

| ||

|

| ||

Continuous stock; 6.5” or | Disabled | At | |

greater |

| without any alignment (unless the RTC option is installed). | |

reflective stocks; multiple |

|

| |

form lengths |

|

| |

6.5” or less | Automatic | Use for easy label length changes, and to automatically set the | |

and reflective stocks |

| maximum label length. Press and hold the FEED Button four | |

|

| seconds and the printer will automatically measure the label | |

|

| length. Once loaded and aligned subsequent | |

|

| result in no wasted labels. | |

| Enabled | Use for constant label lengths. Specify the Label Alignment | |

|

| Length using the <STX>KcAL command or the Setup Menu. | |

|

| Press and hold the FEED Button four seconds, or toggle | |

|

| printer power, then the printer will align with the specified | |

|

| length. | |

6.5” or less | Automatic | This mode of operation requires a Label Alignment Length or | |

and reflective stocks with |

| that Label Alignment be set to AUTO. If either of these | |

the Present Sensor enabled |

| conditions is not met, the printer will not perform the | |

|

| alignment. |

Label Alignment Length – This length, measured from leading edge to leading edge of two successive labels, must be provided to the nearest hundredth of an inch. The number of labels that can be fit between the Media Sensor and the printhead will magnify any error in label alignment length. Errors are more favorable on the low side than on the high side.

Media Type – Sets printing for either direct thermal media or thermal transfer media.

No Paper Min / No Paper Min Reflective – Sets the Media Sensor reading for the Out Of Stock condition.

31 |