ATCA-S201

Contact Address

Contents

NEW System Configuration

RAID Volume Configuration

NFS/SMB Share Setup Tools

RTM-ATCA-SXXX Installation

List of Figures

List of Tables

114

Preface

Safety Summary

Flammability

Safety Statement

EMI Caution

CE Notice European Community

Preface

How this manual is organized

About This Manual

Conventions Used in This Manual

Part Number Description

Ctrl

6806800H62B ATCA‐S201 Installation and Use Guide

Unpacking Instructions

Hardware Preparation and Installation

Antistatic Precautions

ATCA-S201 Overview

Features of the Atca Storage Module

I/O Picmg standards compliance

Power Module

Chassis I/O connections

X1 SAS

Zone 3, Advanced RTM connector

Zone 1, power backplane connections

AMC card connections

Zone 2, backplane connections

Ethernet Management port

Front view- fully populated ATCA-S201 showing panel LEDs

LEDs

Part Number, Serial Number, and Address Labels

Software driver support

Label Description

LED functional description

ATCA-S201 Diagram Showing Identification Label Location

Installation and removal of the Atca carrier blade

ATCA-S201 Installation

Important information about your chassis

Observe maximum module current requirements

Observe ESD Precautions

Before you install or Remove the Atca carrier blade

Watch for Bent Pins or Other Damage

Use Caution When installing or removing the Atca carrier

Installing the Atca carrier blade

Connector Mechanical keying

Understand Hot Swap

Verify Slot Usage

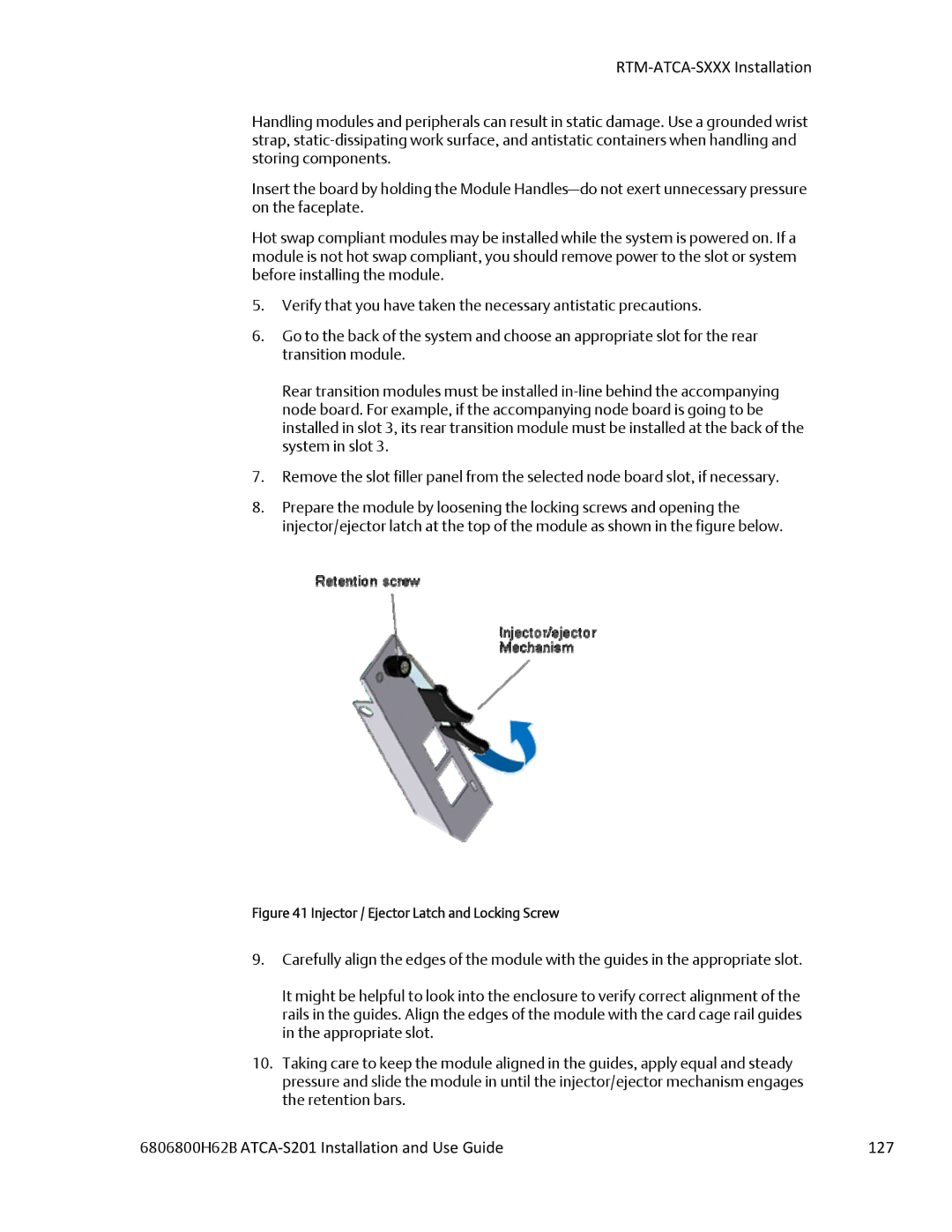

Injector / Ejector latch and locking screw

Removing the Atca carrier blade

Verifying the Hardware Installation

To Verify the Hardware Installation

New System

Configuration Step

RS232 Console port

System boot overview

UImage

Flash boot device contents

Password change procedure

Default blade login accounts and passwords

Password recovery procedure

User account Default Description Password

Configuring a new ATCA-S201 blade

Factory reset

Serial ports

Ethernet ports

Management configuration via serial console shell

Management Configuration via Html browser

Management configuration via secure shell SSH

Perform manual Interactive changes

Command line configuration tool

Change IP address of any Ethernet resource

6806800H62B ATCA‐S201 Installation and Use Guide

Change Network Settings?

Shell, configuration scripting options

Example #2 Additional references

New system configuration, No Dhcp server

Essential U-boot user commands

Boot console tool

Boot command syntax Description

Essential U-boot configuration commands

Boot environment variables shown with printenv

Boot environment variables

Uboot= run flashboot

Manually assign management IP addresses

Bootfile

Uboot= saveenv

Network boot procedure

IP host

Network configuration

Html login screen

Enable Html browser access

CLI command syntax

Html Security certificates https

CLI command syntax, single session management override

Web GUI command

Auto logout inactivity period

Single session management override

Html tool, startup screen

Essential System Configuration Steps

System Identification and Time Zone attributes

Emerson ATCA-S201 Maintenance Network

CLI command syntax, set network property domain name

CLI command syntax, set network property hostname

Hostname

Domain Name

CLI command syntax, set network property system time

CLI command syntax, set network property system date

CLI command syntax, set network property system time zone

Time

Name Server list

CLI command syntax, set network property assign Name server

NTP Server list

World Menu item Daylight savings Menu Item Zone

Ethernet network port identification

CLI command syntax, set network property assign NTP server

Network time protocol NTP On/Off

Dhcp

Enable online/offline

IP address

Network Subnet mask

Gateway

Broadcast

MTU size

MAC address

Example #1 add a vlan interface to Xaui port 4, ID

Vlan Virtual Local Area Network support

Example #2 Remove vlan interfaces on Xaui port 4, ID

Viewing active Vlan

Example #2 list vlan interfaces on Xaui port 4, ID

# vi /etc/network.conf Example remove these 12 lines

Link aggregation 802.3ad bonding, theory of operation

Link aggregation and bonding

Create new bond

Bonding, CLI command syntax

Shelf communications

Blade 1 Primary Configuration

Shelf Address

192.68.100.32 127.0.0.1

Shelf configuration menu parameters

Blade 1 Configuration IPMB-Address Hex for ATCA-S201

10 I/O Status attributes

StorBlade99 ATCA-S201 IO Status

Blade, I/O Status indication

Blade maintenance, miscellaneous operations

StorBlade99 ATCA-S201 Maintenance

Rescan SAS Topology, disk refresh

Software Reset SAS Controller

Reset I/O Status counters

CPU Status attributes

Html tool, Emerson ATCA-S201 MaintenanceCPU Status

Atca Status attributes

Html tool, Emerson ATCA-S201 MaintenanceATCA Status

Atca status indication

Button usage

Svid

Ssid

Atcablade getstatus 2 +

Hardware RAID configuration

Hardware RAID configuration Menu usage

Jbod mode

Parameter Description

CLI command syntax, setraid Add RAID configuration

RAID1/E

RAID0

How new RAID definitions alter device menu display

Important considerations and volume restrictions

Hardware RAID levels and capabilities

Section

Modify existing RAID configurations

Wwid

Hardware RAID Description Configuration

Understanding the Hardware RAID status table

Software RAID web-configuration menu usage

Software RAID configuration

Parameter

RAID0 RAID1 RAID4 RAID5 RAID6

CLI command syntax, mdadm manage RAID configuration

Software RAID, CLI command syntax

Remove volume

Software RAID levels and capabilities

Description Data Layout Diagram Level

Benefits of a Logical device/disk /dev/vga/lva0

Benefits of a logical Volume Group /dev/vga

Emerson ATCA-S201 Physical Disks

Viewing Physical disks

Interpreting physical disk status

Disk view refresh, Re-draw Tree button

View physical disk properties

Emerson ATCA-S201 LVM2 LVM2 Configuration

Create a logical Volume Group /dev/vga

Html tool, Emerson ATCA-S201 LVM2 Configuration

Follow these instructions to create a new volume group

Atcablade setlvm2 Y Ydisk Ndisk Y Y +

CLI command syntax, create new volume groups

Creating a Logical Device /dev/vga/lva0

CLI command syntax, create new logical device

Extend/Expand a Logical Device /dev/vga/lva0

Follow these instructions to create a new logical device

Delete a Logical device /dev/vga/lva0

Commit a logical drive for iSCSI service

Manage shares prepare logical device for service

Block

File

Follow these instructions to assign iSCSI service

Commit a logical drive for NAS service

Follow these instructions to assign NAS service

CLI command syntax, create iSCSI share

Emerson ATCA-S201 Shares Manage Shares

CLI command syntax, format a logical volume

Un-commit an iSCSI share

Follow these instructions to un-commit a logical drive

Un-commit an NFS/SMB share

Mnt/shr/block/lva0 /mnt/shr/block/lva0

StorBlade99 ATCA-S201 Shared Resource /dev/vga/lva0

Re-name iSCSI shares, make more ‘human-friendly’

ISCSI configuration menu

ISCSI device setup tools

Emerson ATCA-S201 iSCSI iSCSI Configuration

Add or create an iSCSI target

Click the ‘add an iSCSI Target’ button

Add or create an iSCSI LUN

Follow these instructions to create a new iSCSI target

LUNs Served By This Target

Target iqn.1995-07.com.emersonATCA-S201.Target0

Lva0 ˇ

Fol

Delete an iSCSI Target and all Luns

Remove an individual iSCSI LUN

Follow these instructions to delete an iSCSI LUN

Follow these instructions to delete an iSCSI Target

Sample ietd.conf file for iSCSI targets

Advanced iSCSI configuration expert mode

6806800H62B ATCA‐S201 Installation and Use Guide

Default

IncomingUser username password

#Wthreads value

Etc/initiators.allow Etc/initiators.deny

ISCSI Discovery filter configuration expert mode

NFS and SMB mount point configuration menus

NFS/SMB Share setup tools

Rw,sync,nowdelay,rootsquash

Nfs export /export/nfs/lvb0 Update

Export an nfs or smb share

Nfs menu

CLI command syntax, create nfs share

Services, such Microsoft Windows

Emerson ATCA-S201 smb smb Configuration

Smb menu

Follow these instructions to Delete a file-share export

CLI command syntax, create smb share

Remove an individual file-share Export

Sample /etc/export file for nfs file shares

Advanced file share configuration expert mode

Sample smb.conf file for samba/CIFs file shares

Common nfs export option definitions

Export option syntax

Exporthost1options hostNoptions

Blade Maintenance

Blade Maintenance Firmware upgrades

Backup your blade configuration

Export System configuration file using web-GUI tool

Export system configuration file using CLI

Import restore a blade configuration

Import System configuration using web-GUI tool

Import System configuration using CLI

Web flash tool, update procedure details

Normal Firmware Update procedures

Download New Firmware package

File Description

StorBlade99 ATCA-S201 System Maintenance

Upgrade firmware procedure

Backup/nvdisk.tar.gz

Follow these instructions to load new firmware

Sbflash -r -k -u -t tftpserverIP

Flashupdate.sh tool usage and options

6806800H62B ATCA‐S201 Installation and Use Guide 100

CLI flash tool, update procedure details

Jumper Settings

Emergency firmware recovery, theory of operation

6806800H62B ATCA‐S201 Installation and Use Guide 101

JP1, jumper for primary/recovery Flash selection

6806800H62B ATCA‐S201 Installation and Use Guide 102

Emergency flash recovery factory reset

DDR2 Dimm

SAS

root password reset procedure method

Clear root password

6806800H62B ATCA‐S201 Installation and Use Guide 103

Tftpboot

# reboot

6806800H62B ATCA‐S201 Installation and Use Guide 104

Physical dimensions

Specifications for the ATCA-S201

Power Requirements

Environmental Specifications and Compliance

Specification Value

Environmental specifications for the ATCA-S201

Nebs Compliance

Electromagnetic Compliance

EMC Emission compliancy

Connectors and Pin assignments

6806800H62B ATCA‐S201 Installation and Use Guide 107

AMC Module Slots

6806800H62B ATCA‐S201 Installation and Use Guide 108

AMC.3 PCI Express

6806800H62B ATCA‐S201 Installation and Use Guide 109

CLK1 Clock AMC-AMC CLK2 CLK3

Extended

6806800H62B ATCA‐S201 Installation and Use Guide 110

Zone 1 Connectors

6806800H62B ATCA‐S201 Installation and Use Guide 111

Zone 2 Connectors

Connector J23, Zone-2 Signal Descriptions

Zone 3 Connectors

6806800H62B ATCA‐S201 Installation and Use Guide 112

6806800H62B ATCA‐S201 Installation and Use Guide 113

Row# Interface

6806800H62B ATCA‐S201 Installation and Use Guide 114

Connector J33, PCIe and Miscellaneous RTM Pin Assignments

Fclka PCIRST# RTM# PCICFG#

6806800H62B ATCA‐S201 Installation and Use Guide 115

Connector J30, RTM Power Pin Signal Descriptions

6806800H62B ATCA‐S201 Installation and Use Guide 116

Ipmi Ipmiscll Ipmisdal

Ipmiscll Ipmisdal 12VPP

6806800H62B ATCA‐S201 Installation and Use Guide 117

Power Supply Mezzanine Module

Sodimm DDR Module

CCL

Overview

Features of the Advanced Rear Transition Module

11.2 I/O Picmg Standards Compliance

11.3 I/O Interfaces

10BRTM‐ATCA‐SXXX Overview

External SAS Connector

Ethernet Management Port RJ-45

LEDs On RTM Faceplate

6806800H62B ATCA‐S201 Installation and Use Guide 120

Serial Console Port RJ-45

Software Support

6806800H62B ATCA‐S201 Installation and Use Guide 121

Products Supported by this Manual

Identification Labels

RTM-ATCA-SXXX Identification Labels

6806800H62B ATCA‐S201 Installation and Use Guide 122

RTM-ATCA-SXXX Diagram Showing Identification Label Locations

6806800H62B ATCA‐S201 Installation and Use Guide 123

Installation and Removal of the Rear Transition Module

Installation

Module Current

No Disk

OFF State Less than Less than 0.4 W

Before You Install Or Remove The RTM

Two disk version No Disk

Installing the Advanced Rear Transition Module

Use Caution When Installing or Removing RTM

RTM‐ATCA‐SXXX Installation

6806800H62B ATCA‐S201 Installation and Use Guide 126

6806800H62B ATCA‐S201 Installation and Use Guide 127

Removing the Advanced Rear Transition Module

6806800H62B ATCA‐S201 Installation and Use Guide 128

Specifications for the RTM-ATCA-SXXX

Mechanical and Connector Information

Module Current ATCA-S201-0 No Disk

ATCA-S201-2 Two disk version

RTM-ATCA-SXXX Mechanical and Connector Information

RTM‐ATCA‐SXXX Mechanical and Connector Information

6806800H62B ATCA‐S201 Installation and Use Guide 131

6806800H62B ATCA‐S201 Installation and Use Guide 132

SAS Connector Port

RTM‐ATCA‐SXXX Mechanical and Connector Information

RTM-ATCA-SXXX Front Panel SAS Connector Pin Assignments

6806800H62B ATCA‐S201 Installation and Use Guide 133

10/100/1000 Management Port Connector Pin Assignments

13.2.2 10/100/1000 Mb Management Port

Serial Console Management Port Connector Pin Assignments

6806800H62B ATCA‐S201 Installation and Use Guide 134

Serial Console Management Port

RTS GND DTR RXD TXD DSR CTS

Connector P32, Management Infrastructure Pin Assignments

6806800H62B ATCA‐S201 Installation and Use Guide 135

Connector J33, Miscellaneous RTM Pin Assignments

6806800H62B ATCA‐S201 Installation and Use Guide 136

J30, RTM Power Pin Header Assignment

6806800H62B ATCA‐S201 Installation and Use Guide 137

Connector J33, Miscellaneous RTM Signal Descriptions

6806800H62B ATCA‐S201 Installation and Use Guide 138

Sensor data records

Ipmi Functions List

Ipmi and Management Controller Ipmc

ID String

Sensor

ATCA-S201 Sensor Data Records

UNR UNC LNC LNR

RTM e-Keying Port Assignments

6806800H62B ATCA‐S201 Installation and Use Guide 14‐2

Ipmi Functions List

RTM-ATCA-SXXX Example FRU Data Records

6806800H62B ATCA‐S201 Installation and Use Guide 14‐3

Supported Ipmi Commands

SAS2

SAS3

Atca Commands

6806800H62B ATCA‐S201 Installation and Use Guide 14‐4

Supported Ipmi Commands

Ipmitool utility

Ipmc Firmware Upgrade Procedure

6806800H62B ATCA‐S201 Installation and Use Guide 15‐2

Ipmc Firmware Upgrade Procedure

RAID

Index

NFS

Vlan

6806800H62B ATCA‐S201 Installation and Use Guide 16‐4

Index