Instruction Manual

Model NGA 2000 TO2

3-3 STARTUP & INITIALIZATION

Establish sample or zero gas flow through the analyzer module at a nominal flow rate of 2 SCFH (1 l/min). Allow gas to flow for 15 to 30 seconds before applying power. Apply power to the TO2 Analyzer Module.

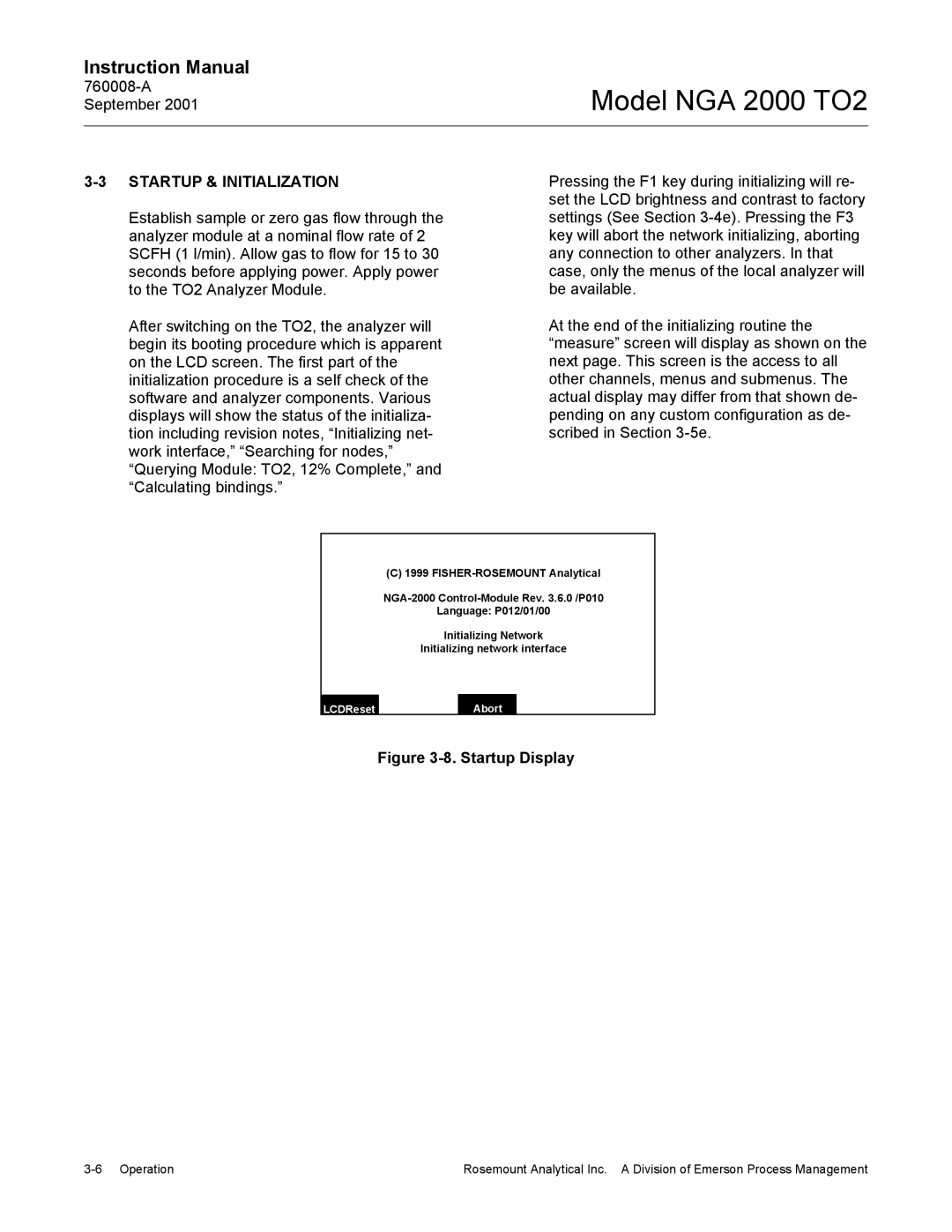

After switching on the TO2, the analyzer will begin its booting procedure which is apparent on the LCD screen. The first part of the initialization procedure is a self check of the software and analyzer components. Various displays will show the status of the initializa- tion including revision notes, “Initializing net- work interface,” “Searching for nodes,” “Querying Module: TO2, 12% Complete,” and “Calculating bindings.”

Pressing the F1 key during initializing will re- set the LCD brightness and contrast to factory settings (See Section

At the end of the initializing routine the “measure” screen will display as shown on the next page. This screen is the access to all other channels, menus and submenus. The actual display may differ from that shown de- pending on any custom configuration as de- scribed in Section

(C) 1999

Language: P012/01/00

Initializing Network

Initializing network interface

LCDReset

Abort

Figure 3-8. Startup Display

Rosemount Analytical Inc. A Division of Emerson Process Management |