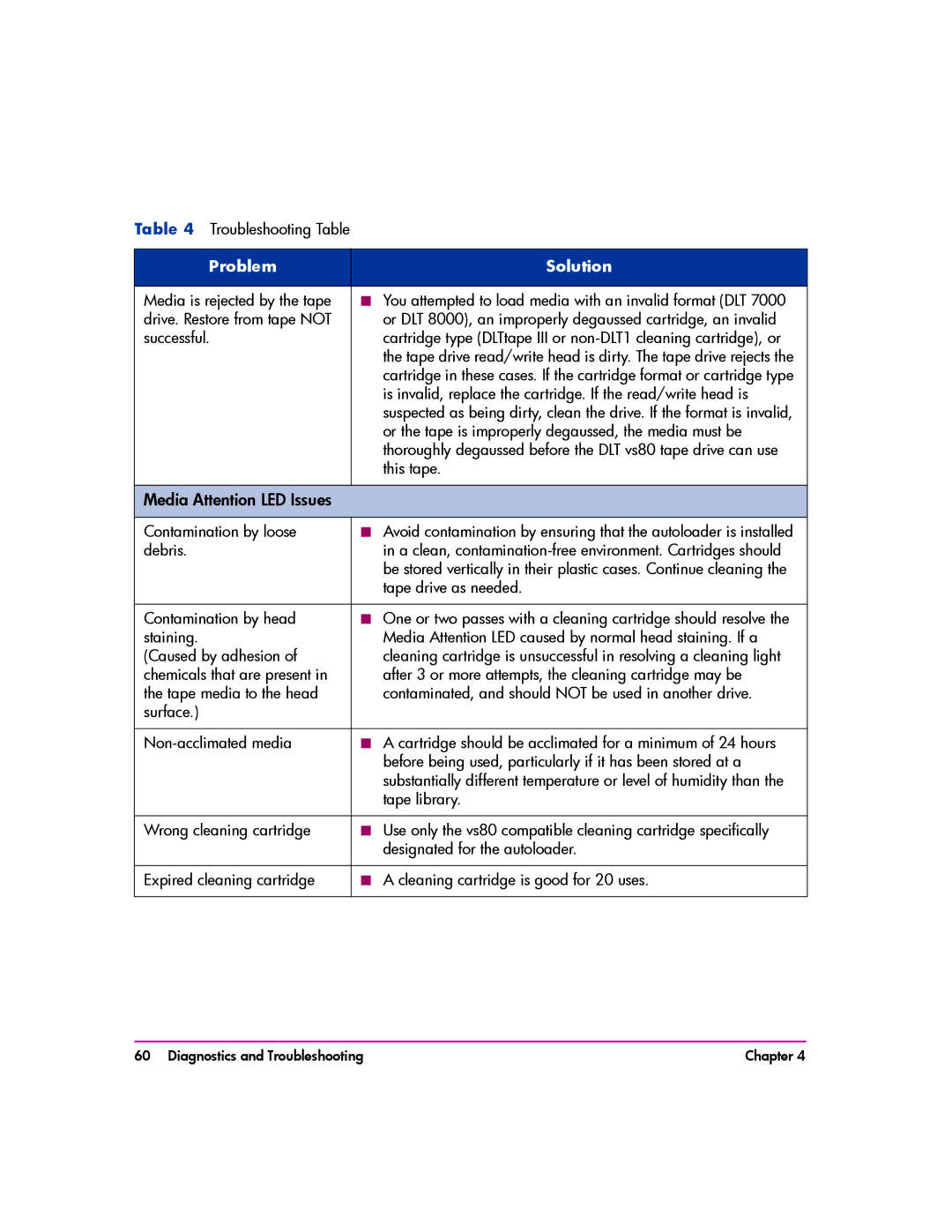

Table 4 Troubleshooting Table

Problem | Solution |

|

|

Media is rejected by the tape | ■ You attempted to load media with an invalid format (DLT 7000 |

drive. Restore from tape NOT | or DLT 8000), an improperly degaussed cartridge, an invalid |

successful. | cartridge type (DLTtape III or |

| the tape drive read/write head is dirty. The tape drive rejects the |

| cartridge in these cases. If the cartridge format or cartridge type |

| is invalid, replace the cartridge. If the read/write head is |

| suspected as being dirty, clean the drive. If the format is invalid, |

| or the tape is improperly degaussed, the media must be |

| thoroughly degaussed before the DLT vs80 tape drive can use |

| this tape. |

|

|

Media Attention LED Issues |

|

|

|

Contamination by loose | ■ Avoid contamination by ensuring that the autoloader is installed |

debris. | in a clean, |

| be stored vertically in their plastic cases. Continue cleaning the |

| tape drive as needed. |

|

|

Contamination by head | ■ One or two passes with a cleaning cartridge should resolve the |

staining. | Media Attention LED caused by normal head staining. If a |

(Caused by adhesion of | cleaning cartridge is unsuccessful in resolving a cleaning light |

chemicals that are present in | after 3 or more attempts, the cleaning cartridge may be |

the tape media to the head | contaminated, and should NOT be used in another drive. |

surface.) |

|

|

|

■ A cartridge should be acclimated for a minimum of 24 hours | |

| before being used, particularly if it has been stored at a |

| substantially different temperature or level of humidity than the |

| tape library. |

|

|

Wrong cleaning cartridge | ■ Use only the vs80 compatible cleaning cartridge specifically |

| designated for the autoloader. |

|

|

Expired cleaning cartridge | ■ A cleaning cartridge is good for 20 uses. |

|

|

60 Diagnostics and Troubleshooting | Chapter 4 |