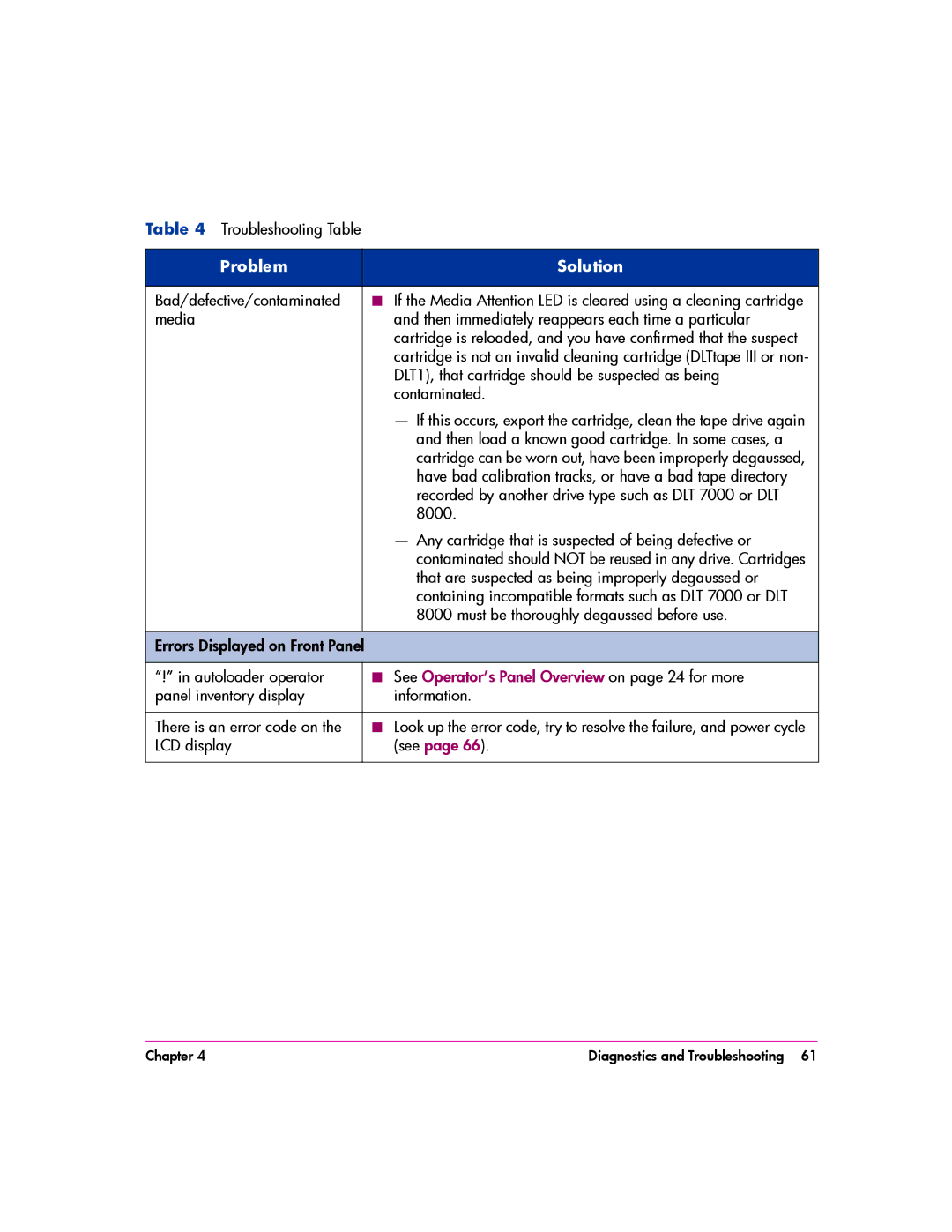

Table 4 Troubleshooting Table

Problem | Solution |

|

|

Bad/defective/contaminated | ■ If the Media Attention LED is cleared using a cleaning cartridge |

media | and then immediately reappears each time a particular |

| cartridge is reloaded, and you have confirmed that the suspect |

| cartridge is not an invalid cleaning cartridge (DLTtape III or non- |

| DLT1), that cartridge should be suspected as being |

| contaminated. |

| — If this occurs, export the cartridge, clean the tape drive again |

| and then load a known good cartridge. In some cases, a |

| cartridge can be worn out, have been improperly degaussed, |

| have bad calibration tracks, or have a bad tape directory |

| recorded by another drive type such as DLT 7000 or DLT |

| 8000. |

| — Any cartridge that is suspected of being defective or |

| contaminated should NOT be reused in any drive. Cartridges |

| that are suspected as being improperly degaussed or |

| containing incompatible formats such as DLT 7000 or DLT |

| 8000 must be thoroughly degaussed before use. |

|

|

Errors Displayed on Front Panel

“!” in autoloader operator | ■ | See Operator’s Panel Overview on page 24 for more |

panel inventory display |

| information. |

|

|

|

There is an error code on the | ■ | Look up the error code, try to resolve the failure, and power cycle |

LCD display |

| (see page 66). |

|

|

|

Chapter 4 | Diagnostics and Troubleshooting 61 |