80445190

OPERATION AND MAINTENANCE MANUAL

C.C.N

DATE

Warranty

AIR COMPRESSOR GROUP BONDED WARRANTY & REGISTERED START UP

Ingersoll Rand Air Solutions Group Global Aftermarket Division

Register on-line at http//air.ingersollrand.com

10 GENERAL INFORMATION 12 INSTALLATION / HANDLING

CONTENTS & ABBREVIATIONS

CONTENTS 1 CONTENTS 2 FOREWORD 3 DECALS 8 SAFETY

40 MAINTENANCE 47 TROUBLE SHOOTING

IF IN DOUBT CONSULT SUPERVISION

2 FOREWORD

b May impair the safety of users and other persons, and

The use of the machine in any of the situation types listed in table

Prohibition / Mandatory

DECALS ISO SYMBOLS

GRAPHIC FORM AND MEANING OF ISO SYMBOLS

Information / Instructions

CLEAN

4 DECALS

POWER

INSPECT

DANGER

DECALS ANSI SYMBOLS

GRAPHIC FORM AND MEANING OF ANSI SYMBOLS

6 DECALS - ANSI

DECALS - ANSI

60 Hz Units

8 SAFETY

SAFETY

Condensate disposal

10 GENERAL INFORMATION

22292783 Rev F

40.Refrigerant compressor, dryer option

GENERAL INFORMATION

38.Condenser, dryer option 39.Evaporator, dryer option

41.Hot gas bypass valve, dryer option

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50-PE, EP50-PE

12 INSTALLATION / HANDLING

http//air.ingersollrand.com

HP50-PE, HXP50-PE

INSTALLATION / HANDLING

14 INSTALLATION / HANDLING

UP6 50PE UP6 50PEI

INSTALLATION / HANDLING

60Hz

HF50-PE

60Hz

16 INSTALLATION / HANDLING

Re-wiring should only be effected by a competent Electrician

UP6 30E-HA

Dew point temperature at rated

INSTALLATION / HANDLING

Control settings

DRYER OPTION TECHNICAL INFORMATION 60Hz

INSTALLATION / HANDLING

INSTALLATION / HANDLING

128.3A

All data applies to standard product only ELECTRICAL DATA

20 INSTALLATION / HANDLING

disconnecting the electronic controller where fitted

Do not direct the airflow at face or eyes

OPERATING INSTRUCTIONS - GENERAL

GENERAL OPERATION

22 OPERATING INSTRUCTIONS - ELECTRO-PNEUMATIC

FUNCTION TEST

OPERATING INSTRUCTIONS - ELECTRO-PNEUMATIC

NORMAL/EMERGENCY STOPPING

24 OPERATING INSTRUCTIONS - ELECTRO-PNEUMATIC

FULL VOLTAGE WIRING SCHEMATIC

Switch, high refrigerant pressure option

OPERATING INSTRUCTIONS - ELECTRO-PNEUMATIC

26 OPERATING INSTRUCTIONS - ELECTRO-PNEUMATIC

STAR - DELTA WIRING SCHEMATIC

OPERATING INSTRUCTIONS - ELECTRO-PNEUMATIC

28 OPERATING INSTRUCTIONS - ELECTRO-PNEUMATIC

OPERATING INSTRUCTIONS - INTELLISYS OPTION

30 OPERATING INSTRUCTIONS - INTELLISYS OPTION

DISPLAY MESSAGES

CONTROLLER ALARMS

OPERATING INSTRUCTIONS - INTELLISYS OPTION

32 OPERATING INSTRUCTIONS - INTELLISYS OPTION

72% CAPACITY

OPERATING INSTRUCTIONS - INTELLISYS w/ MODULATION CONTROL

85% CAPACITY

60% CAPACITY

Fault Analysis

34 OPERATING INSTRUCTIONS - INTELLISYS w/ PORO OPTION

OPERATION POWER OUTAGE RESTART OPTION

Function test

Overload, dryer compressor option

OPERATING INSTRUCTIONS - INTELLISYS OPTION

Contactor, dryer compressor option

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50-PE

36 OPERATING INSTRUCTIONS - INTELLISYS OPTION

STAR - DELTA WIRING SCHEMATIC

OPERATING INSTRUCTIONS - INTELLISYS OPTION

38 OPERATING INSTRUCTIONS - INTELLISYS OPTION

ADAPTER INTO

OPERATING INSTRUCTIONS - INTELLISYS OPTION

9. Valve, solenoid blowdown 10.Valve, solenoid load

THIS PORT

MAINTENANCE

40 MAINTENANCE

SSR UP Series Maintenance Schedule

PERIOD

MAINTENANCE

DRYER MAINTENANCE DRYER OPTION

42 MAINTENANCE

SEPARATOR CARTRIDGES CHANGE PROCEDURE

Oil level checking procedure

TO ADJUST THE UPPER SET POINT

MAINTENANCE

SETTING THE PRESSURE SWITCH where used

TO ADJUST THE LOWER SET POINT

MOISTURE SEPARATOR MAINTENANCE

44 MAINTENANCE

BELT CHANGE / GAS STRUT CHANGE PROCEDURE

Strainer Ball Valve

MAINTENANCE

Apply power

The Electric Drain Valve removes condensed water and oil from the

FIGURE 2 MODULATION VALVE

46 MAINTENANCE

MODULATE CONTROL VALVE ADJUSTMENT

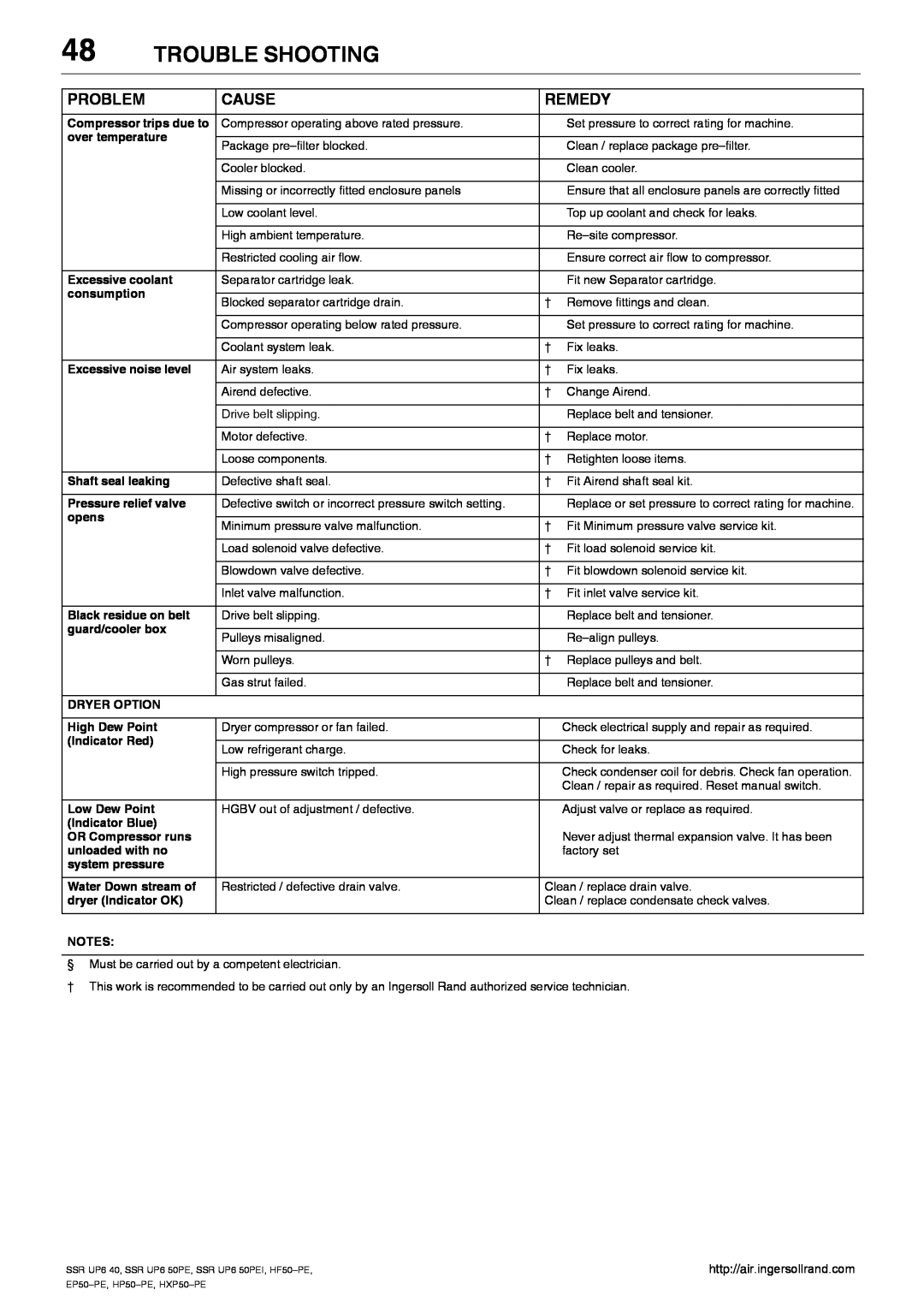

CAUSE

TROUBLE SHOOTING

PROBLEM

REMEDY

over temperature

TROUBLE SHOOTING

PROBLEM

CAUSE

Octubre

MANUAL DE MANEJO Y MANTENIMIENTO

FECHA

2008

air.ingersollrand.com

GRUPO DE COMPRESORES DE AIRE GARANTIA Y ARRANQUE REGISTRADO

Para registrarse en línea, entrar en air.ingersollrand.com

Garantía

10 INFORMACION GENERAL 12 INSTALACIÓN / MANEJO

CONTENIDO & ABREVIATURAS

CONTENIDO 1 CONTENIDO 2 PREAMBULO 3 CALCOMANIAS 8 SEGURIDAD

INSTRUCCIONES DE OPERACION

2 PREAMBULO

Uso de la máquina con componentes no aprobados por Ingersoll Rand

Prohibición/Obligatoriedad

CALCOMANIAS SIMBOLOS ISO

FORMA GRAFICA Y SIGNIFICADO DE LOS SIMBOLOS ISO

Información/Instrucciones

INSPECCIONAR

4 CALCOMANIAS

ENERGIA ELECTRICA

LIMPIAR

ADVERTENCIA

CALCOMANIAS SIMBOLOS ANSI

PELIGRO

FORMA GRAFICA Y SIGNIFICADO DE LOS SIMBOLOS ANSI

Elemento ccn

6 CALCOMANIAS - ANSI

Unidades de 60 Hz

Cantidad

Elemento ccn

CALCOMANIAS - ANSI

Unidades de 60 Hz

Cantidad

8 SEGURIDAD

Eliminación del condensado

SEGURIDAD

ADVERTENCIA

22292783 Rev F

10 INFORMACION GENERAL

CONDUCTOS E INSTRUMENTACION - Unidades electroneumáticas e Intellisys

CLAVE

INFORMACION GENERAL

ROTACION VISTA IZQUIERDA VISTA POSTERIOR

12 INSTALACIÓN / MANEJO

Nota Dimensiones expresadas en mm pulgadas

VISTA FRONTAL

INSTALACIÓN / MANEJO

14 INSTALACIÓN / MANEJO

60Hz

INSTALACIÓN / MANEJO

UP6 50PE

UP6 50PEI

UP6 30E-HA

16 INSTALACIÓN / MANEJO

60Hz

UP6 40-HA

Generalidades

INSTALACIÓN / MANEJO

INFORMACION TECNICA DE LA OPCIÓN DE SECADOR 60Hz

Ajustes de control

INSTALACIÓN / MANEJO

INSTALACIÓN / MANEJO

20 INSTALACIÓN / MANEJO

INSTRUCCIONES DE FUNCIONAMIENTO - GENERALIDADES

22 INSTRUCCIONES DE FUNCIONAMIENTO - ELECTRONEUMATICO

INSTRUCCIONES DE FUNCIONAMIENTO - ELECTRONEUMATICO

LEYENDA

24 INSTRUCCIONES DE FUNCIONAMIENTO - ELECTRONEUMATICO

ESQUEMA DE CABLEADO - PLENA TENSION

Interruptor, alta presión del refrigerante opción

INSTRUCCIONES DE FUNCIONAMIENTO - ELECTRONEUMATICO

Relé, rearranque, retardo de tiempo 6 minutos

Válvula, solenoide carga Normalmente cerrada

26 INSTRUCCIONES DE FUNCIONAMIENTO - ELECTRONEUMATICO

1Ma, b, c

NOTAS

INSTRUCCIONES DE FUNCIONAMIENTO - ELECTRONEUMATICO

LEYENDA

28 INSTRUCCIONES DE FUNCIONAMIENTO - ELECTRONEUMATICO

INSTRUCCIONES DE FUNCIONAMIENTO - ELECTRONEUMATICO

2. Cerciorarse de que está abierta la válvula principal de descarga

30 INSTRUCCIONES DE FUNCIONAMIENTO - ELECTRONEUMATICO

descargado

MENSAJES EN PANTALLA

ALARMAS DEL CONTROLADOR

INSTRUCCIONES DE FUNCIONAMIENTO - ELECTRONEUMATICO

32 INSTRUCCIONES DE FUNCIONAMIENTO - ELECTRONEUMATICO

PRESIÓNDE

OPCIÓN DE REARRANQUE EN CASO DE INTERRUPCIÓN DE LA ALIMENTACIÓN

34 INSTRUCCIONES DE FUNCIONAMIENTO - INTELLISYS con OPCION PORO

FUNCIONAMIENTO

Prueba de la función

LEYENDA

INSTRUCCIONES DE FUNCIONAMIENTO - OPCION INTELLISYS

ESQUEMA DE CABLEADO - PLENA TENSION

NOTAS

36 INSTRUCCIONES DE FUNCIONAMIENTO - OPCION INTELLISYS

LEYENDA

LEYENDA

INSTRUCCIONES DE FUNCIONAMIENTO - OPCION INTELLISYS

INSTRUCCIONES DE FUNCIONAMIENTO - OPCION INTELLISYS

NOTAS

38 INSTRUCCIONES DE FUNCIONAMIENTO - OPCION INTELLISYS

LEYENDA

INSTRUCCIONES DE FUNCIONAMIENTO - OPCION INTELLISYS

15.Válvula de solenoide de Lado de la planta / Lado del compresor

PERÍODO

40 MANTENIMIENTO

Programa de mantenimiento de la Serie SSR UP

MANTENIMIENTO

MANTENIMIENTO

42 MANTENIMIENTO

PROCEDIMIENTO DE CAMBIO DEL ELEMENTO DEL FILTRO

MANTENIMIENTO

44 MANTENIMIENTO

MANTENIMEINTO DEL SEPARADOR DE LA HUMEDAD

MANTENIMIENTO

PROCEDIMIENTO PARA CAMBIAR COREAS/MUELLE DE GAS

La válvula eléctrica de vaciado elimina agua condensada y aceite del

MANTENIMIENTO

Válvula esférica del purificador

separador de la humedad. Pueden montarse elementos de drenaje en

FIGURA 2 VÁLVULA DE MODULACIÓN

MANTENIMIENTO

AJUSTE DE LA VÁLVULA DE CONTROL DE MODULACIÓN

CAUSA

RESOLUCION DE AVERIAS

AVERIA

REMEDIO

CAUSA

RESOLUCION DE AVERIAS

AVERIA

REMEDIO

Page

C.C.N

MANUEL D’UTILISATION ET D’ENTRETIEN

Octobre

DATE

Enregistrez-vous directement en ligne sur air.ingersollrand.com

GROUPE DE COMPRESSEUR D’AIR

GARANTIE PAR OBLIGATION ET DEMARRAGE ENREGISTRE

Garantie

ABRÉVIATIONS & SYMBOLES

10 INFORMATIONS GÉNÉRALES 12 INSTALLATION/ MANUTENTION

41 MAINTENANCE 49 RECHERCHE DE DÉFAUTS

CONTENU & ABREVIATIONS

2 AVANT-PROPOS

homologuées par Ingersoll Rand

Interdiction/Obligatoire

DECALS SYMBOLES ISO

STRUCTURE GRAPHIQUE ET SIGNIFICATION DES SYMBOLES ISO

Informations/Instructions

CONTROLER

4 DECALS

PUISSANCE

NETTOYER

AVERTISSEMENT

DECALS SYMBOLES ANSI

STRUCTURE GRAPHIQUE ET SIGNIFICATION DES SYMBOLES ANSI

DANGER

avant

6 DECALS - ANSI

A L’INTERIEUR DE LA PORTE DU DEMARREUR

22248538

22115703

Autocollant, programme de maintenance

DECALS - ANSI

22436760

8 SECURITE

SECURITE

LEXIQUE

10 INFORMATIONS GÉNÉRALES

22292783 Rev F

A D’air/Huile B D’air C Huile D Condensat E Limite composants

INFORMATIONS GÉNÉRALES

http//air.ingersollrand.com

F Réfrigérant G Option

ROTATION VUE DE GAUCHE VUE ARRIERE

12 INSTALLATION / MANUTENTION

Nota Les dimensions sont en mm pouces

VUE DE FACE

DESEMBALLAGE

INSTALLATION / MANUTENTION

LEGENDE

REMARQUE

14 INSTALLATION / MANUTENTION

60Hz

INSTALLATION / MANUTENTION

UP6 50PE

UP6 50PEI

UP6 30E-HA

16 INSTALLATION / MANUTENTION

60Hz

UP6 40-HA

INSTALLATION / MANUTENTION

Réglages des commandes

INSTALLATION / MANUTENTION

INSTALLATION / MANUTENTION

ELECTRICITE

20 INSTALLATION / MANUTENTION

Les caractéristiques techniques ne s’appliquent qu’au modèle standard

ATTENTIO

INSTRUCTIONS DE FONCTIONNEMENT - GENERALITES

22 INSTRUCTIONS DE FONCTIONNEMENT - ELECTRO-PNEUMATIQUE

ARRET NORMAL/D’URGENCE

INSTRUCTIONS DE FONCTIONNEMENT - ELECTRO-PNEUMATIQUE

MISE EN MARCHE

ESSAI DE FONCTIONNEMENT

Fusibles du ventilateur du sécheur option

24 INSTRUCTIONS DE FONCTIONNEMENT - ELECTRO-PNEUMATIQUE

VOIR NOTES 1

Voyant, redémarrage automatique Blanc

INSTRUCTIONS DE FONCTIONNEMENT - ELECTRO-PNEUMATIQUE

Contacteur de pression trop élevée du fluide réfrigérant

LEGENDE

26 INSTRUCTIONS DE FONCTIONNEMENT - ELECTRO-PNEUMATIQUE

SCHEMA DE CABLAGE ETOILE - TRIANGLE

INSTRUCTIONS DE FONCTIONNEMENT - ELECTRO-PNEUMATIQUE

LEGENDE

28 INSTRUCTIONS DE FONCTIONNEMENT - ELECTRO-PNEUMATIQUE

15.Réservoir du séparateur

INSTRUCTIONS DE FONCTIONNEMENT - OPTION INTELLISYS

30 INSTRUCTIONS DE FONCTIONNEMENT - OPTION INTELLISYS

MESSAGES AFFICHES

ALARMES DU CONTROLEUR

INSTRUCTIONS DE FONCTIONNEMENT - OPTION INTELLISYS

32 INSTRUCTIONS DE FONCTIONNEMENT - OPTION INTELLISYS

Commande de modulation

INSTRUCTIONS DE FONCTIONNEMENT. COMMANDES INTELLISYS avec MODULATION

COMMANDE DE MODULATION

CODE

Analyse des erreurs possibles

FONCTIONNEMENT OPTION DE REDÉMARRAGE APRÈS UNE COUPURE D’ALIMENTATION

Test de fonctionnement

Port, communications / test / entretien / séquenceur

INSTRUCTIONS DE FONCTIONNEMENT - OPTION INTELLISYS

Capteur de température d’air du ventilateur option

36 INSTRUCTIONS DE FONCTIONNEMENT - OPTION INTELLISYS

LEGENDE

OPTION PORO

SCHEMA DE CABLAGE ETOILE - TRIANGLE

INSTRUCTIONS DE FONCTIONNEMENT - OPTION INTELLISYS

LEGENDE

38 INSTRUCTIONS DE FONCTIONNEMENT - OPTION INTELLISYS

LEGENDE

INSTRUCTIONS DE FONCTIONNEMENT - OPTION INTELLISYS

15.Electrovalve de ligne / carter

40 MAINTENANCE

Programme de Maintenance Série SSR UP

PÉRIODE

MAINTENANCE

MAINTENANCE

42 MAINTENANCE

PROCEDURE DE CHANGEMENT DE L’ELEMENT FILTRANT

MAINTENANCE DU SECHEUR OPTION SÉCHEUR

MAINTENANCE

PROCEDURE POUR REMPLACER LES CARTOUCHES DU SÉPARATEUR

PROCEDURE DE NETTOYAGE DU RADIATEUR

44 MAINTENANCE

NE DEPASSEZ PAS ces chiffres

ENTRETIEN DU SEPARATEUR D’HUMIDITE

MAINTENANCE

PROCEDURE DE CHANGEMENT DE LA COUROIE / RESSORT A GAZ

Le robinet ne se

MAINTENANCE

Robinet à boisseau de la trémie

FIGURE 2 VALVE DE COMMANDE DE MODULATION

MAINTENANCE

RÉGLAGE DE LA VALVE DE COMMANDE DE MODULATION

DEFAUT

SOLUTION

RECHERCHE DE DÉFAUTS

CAUSE

DEFAUT

SOLUTION

RECHERCHE DE DÉFAUTS

CAUSE

Page

Outubro

MANUAL DE OPERAÇAO E CONSERVAÇAO

DATA

C.C.N

Garantia

GRUPO COMPRESSOR DE AR GARANTIA FORMAL E ARRANQUE REGISTADO

Registo ’on-line’ em air.ingersollrand.com

Ingersoll Rand Air Solutions Group Global Aftermarket Division

10 INFORMAÇÃO GERAIS 12 INSTALAÇÃO / MANUSEAMENTO

ÍNDICE & ABREVIATURAS

ÍNDICE 1 ÍNDICE 2 INTRODUÇÃO 3 AUTOCOLANTES 8 SEGURANÇA

INSTRUÇÕES DE OPERAÇÃO

2 INTRODUÇÃO

Ingersoll Rand

Proibição / mandatário

CONFIGURAÇÃO GRÁFICA E SIGNIFICADO DOS SÍMBOLOS ISO

AUTOCOLANTE SÍMBOLOS ISO

Informação / Instruções

http//air.ingersollrand.com

4 AUTOCOLANTE

Cada X meses, se for antes que o exigido pelas horas de trabalho

ADVERTÊNCIA

CONFIGURAÇÃO GRÁFICA E SIGNIFICADO DOS SÍMBOLOS ANSI

AUTOCOLANTE SÍMBOLOS ANSI

PELIGRO

6 AUTOCOLANTES - ANSI

Descrição

AUTOCOLANTES - ANSI

8 SEGURANÇA

SEGURANÇA

22292783 Rev F

10 INFORMAÇÃO GERAL

TUBAGEM E INSTRUMENTAÇÃO - Unidades electropneumáticas e Intellisys

CHAVE

INFORMAÇÃO GERAL

VISTA DE FRENTE

12 INSTALAÇÃO / MANUSEAMENTO

ROTAÇÃO VISTA DA ESQUERDA VISTA DE COSTAS

VISTA DA DIREITA

INSTALAÇÃO / MANUSEAMENTO

14 INSTALAÇÃO / MANUSEAMENTO

60Hz

INSTALAÇÃO / MANUSEAMENTO

UP6 50PE

UP6 50PEI

UP6 30E-HA

16 INSTALAÇÃO / MANUSEAMENTO

60Hz

UP6 40-HA

Geral

INSTALAÇÃO / MANUSEAMENTO

INFORMAÇÃO TÉCNICA OPÇÃO COM SECADOR 60Hz

Regulações de controlo

INSTALAÇÃO / MANUSEAMENTO

INSTALAÇÃO / MANUSEAMENTO

20 INSTALAÇÃO / MANUSEAMENTO

INSTRUÇÕES DE FUNCIONAMENTO - GERAL

22 INSTRUÇÕES DE FUNCIONAMENTO - ELECTROPNEUMÁTICA

INSTRUÇÕES DE FUNCIONAMENTO - ELECTROPNEUMÁTICA

SSR UP6 40, SSR UP6 50PE, SSR UP6 50PEI, HF50-PE

24 INSTRUÇÕES DE FUNCIONAMENTO - ELECTROPNEUMÁTICA

http//air.ingersollrand.com

EP50-PE, HP50-PE, HXP50-PE

Luz, indicador de rearranque automático Branco

INSTRUÇÕES DE FUNCIONAMENTO - ELECTROPNEUMÁTICA

VEJA NOTAS 1

26 INSTRUÇÕES DE FUNCIONAMENTO - ELECTROPNEUMÁTICA

Verifique as ligações reais do motor eléctrico pelo diagrama do

LEGENDA

INSTRUÇÕES DE FUNCIONAMENTO - ELECTROPNEUMÁTICA

ESQUEMA ELÉCTRICO ESTRELA - TRIÂNGULO

Relé, rearranque, tempo espera 6 minutos

28 INSTRUÇÕES DE FUNCIONAMENTO - ELECTROPNEUMÁTICA

Interruptor, pressão de refrigerante alta opção

LEGENDA

DIAGRAMA DA TUBAGEM DE CONTROLO

INSTRUÇÕES DE FUNCIONAMENTO - ELECTROPNEUMÁTICA

NOTAS

30 INSTRUÇÕES DE FUNCIONAMENTO - OPÇÃO INTELLISYS

INSTRUÇÕES DE FUNCIONAMENTO - OPÇÃO INTELLISYS

MENSAGENS NO VISOR

32 INSTRUÇÕES DE FUNCIONAMENTO - OPÇÃO INTELLISYS

ALARMES DO CONTROLADOR

INSTRUÇÕES DE FUNCIONAMENTO - OPÇÃO INTELLISYS

Indica falha do transdutor de pressão/ avaria do cabo de ligação

CÓDIGO

34 INSTRUÇÕES DE FUNCIONAMENTO - INTELLISYS com CONTROLO DE MODELAÇÃO

CONTROLO DE MODULAÇÃO

FIGURA CONTROLO ACS INTELLISYS c/ OPÇÃO DE MODULAÇÃO APENAS

Análise de Avarias

OPERAÇÃO OPÇÃO DE REARRANQUE APÓS FALHA DE CORRENTE

Teste de funcionamento

36 INSTRUÇÕES DE FUNCIONAMENTO - OPÇÃO INTELLISYS

Porta, comunicações / ensaio / serviço / sequenciador

NOTAS

INSTRUÇÕES DE FUNCIONAMENTO - OPÇÃO INTELLISYS

LEGENDA

LEGENDA

38 INSTRUÇÕES DE FUNCIONAMENTO - OPÇÃO INTELLISYS

ESQUEMA ELÉCTRICO ESTRELA - TRIÂNGULO

INSTRUÇÕES DE FUNCIONAMENTO - OPÇÃO INTELLISYS

Interruptor, pressão ventoinha opção

40 INSTRUÇÕES DE FUNCIONAMENTO - OPÇÃO INTELLISYS

15.Electroválvula linha / reservatório

MANUTENÇÃO

MANUTENÇÃO

Programa de manutenção para a Série SSR UP

PERÍODO

42 MANUTENÇÃO

MANUTENÇÃO

PROCEDIMENTO PARA SUBSTITUIÇÃO DO ELEMENTO DO FILTRO DE AR

44 MANUTENÇÃO

MANUTENÇÃO

NÃO exceda estes valores

MANUTENÇÃO DO SEPARADOR DE HUMIDADE

46 MANUTENÇÃO

PROCEDIMENTO PARA SUBSTITUIÇÃO DE CORREIA / TENSOR DE GÁS

pode ser regulado para drenar automaticamente o reservatório de ar

MANUTENÇÃO

Válvula de esfera do filtro

FIGURA 2 VÁLVULA DE MODULAÇÃO

48 MANUTENÇÃO

AJUSTE DA VÁLVULA DE CONTROLO DA MODULAÇÃO

SOLUÇÃO

DIAGN ÓSTICO DE AVARIAS

AVARIA

CAUSA

CAUSA

DIAGNÓSTICO DE AVARIAS

AVARIA

SOLUÇÃO