| OPERATION | ||

|

|

|

|

|

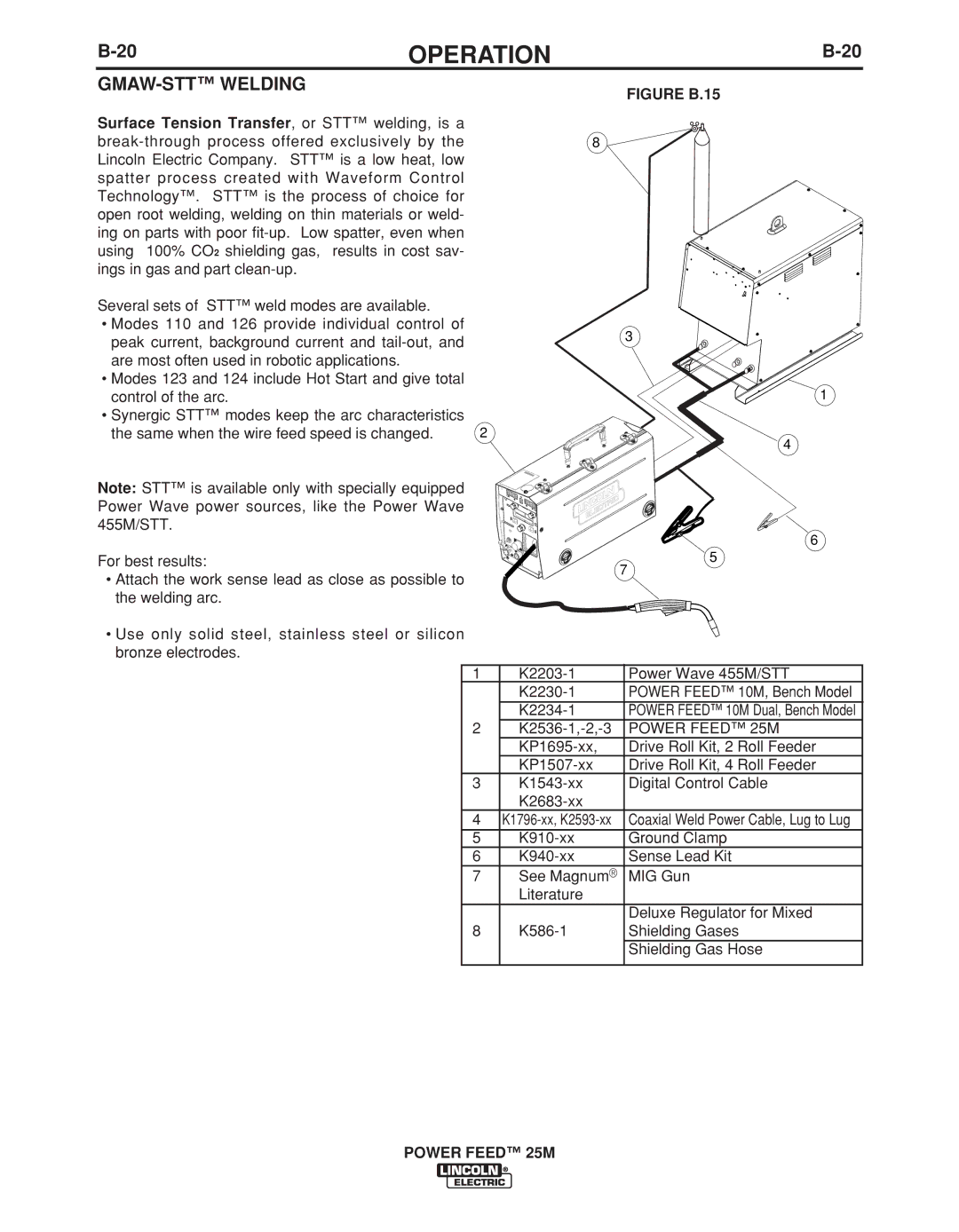

| FIGURE B.15 | |

|

|

| |

Surface Tension Transfer, or STT™ welding, is a

Several sets of STT™ weld modes are available.

•Modes 110 and 126 provide individual control of peak current, background current and

•Modes 123 and 124 include Hot Start and give total control of the arc.

•Synergic STT™ modes keep the arc characteristics

the same when the wire feed speed is changed. | 2 |

Note: STT™ is available only with specially equipped Power Wave power sources, like the Power Wave 455M/STT.

For best results:

•Attach the work sense lead as close as possible to the welding arc.

•Use only solid steel, stainless steel or silicon bronze electrodes.

8 |

3

1

4

6

5

7

1 | Power Wave 455M/STT | |

| POWER FEED™ 10M, Bench Model | |

| POWER FEED™ 10M Dual, Bench Model | |

2 | POWER FEED™ 25M | |

| Drive Roll Kit, 2 Roll Feeder | |

| Drive Roll Kit, 4 Roll Feeder | |

3 | Digital Control Cable | |

|

| |

4 | Coaxial Weld Power Cable, Lug to Lug | |

5 | Ground Clamp | |

6 | Sense Lead Kit | |

7 | See Magnum® | MIG Gun |

| Literature |

|

|

| Deluxe Regulator for Mixed |

8 | Shielding Gases | |

|

| Shielding Gas Hose |

|

|

|