OPERATION | ||

|

|

|

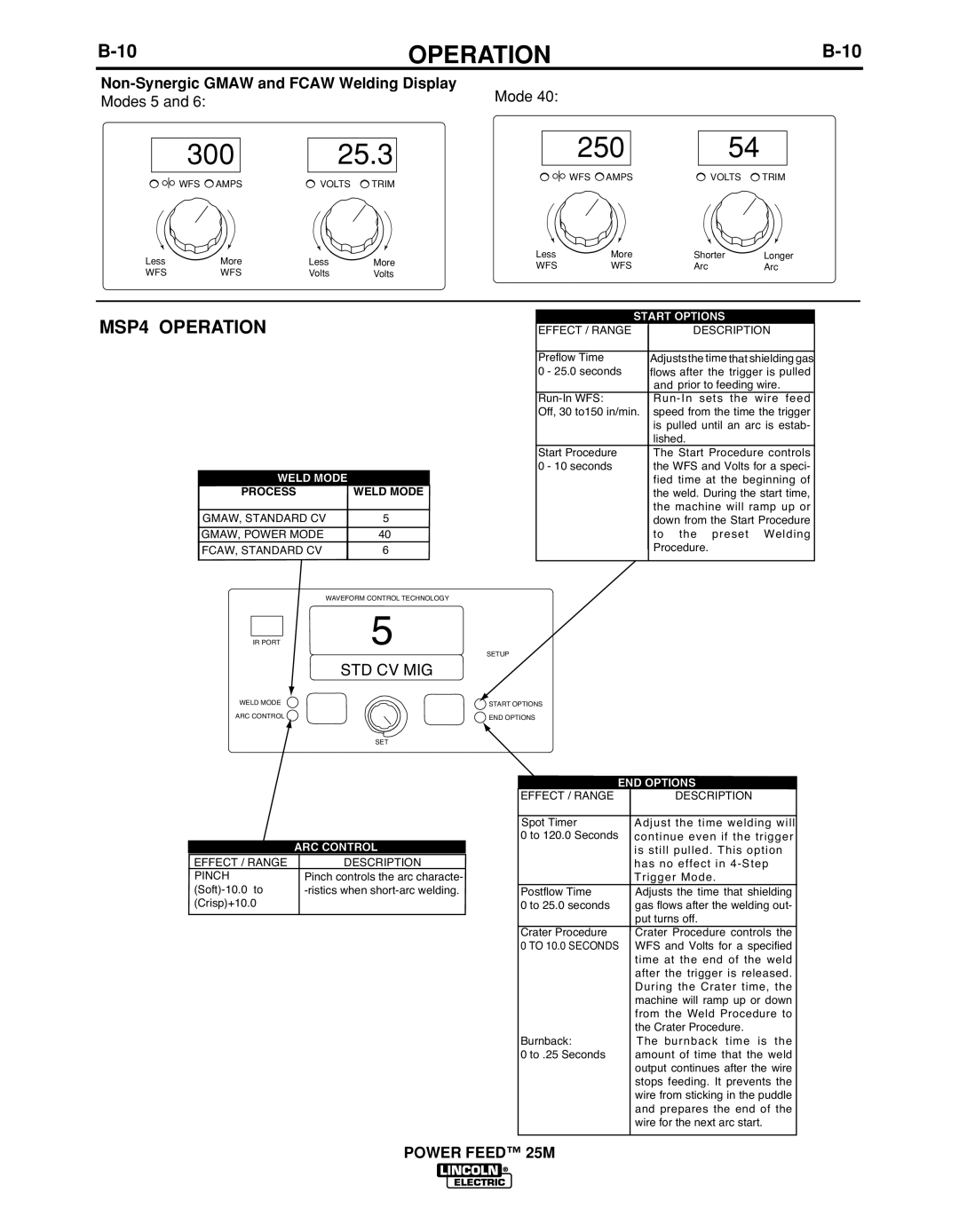

Non-Synergic GMAW and FCAW Welding Display

Modes 5 and 6:

300 | 25.3 |

WFS AMPS | VOLTS TRIM |

Less | More | Less | More |

WFS | WFS | Volts | Volts |

Mode 40:

250 | 54 |

WFS AMPS | VOLTS TRIM |

Less | More | Shorter | Longer |

WFS | WFS | Arc | Arc |

MSP4 OPERATION

WELD MODE

PROCESS | WELD MODE |

|

GMAW, STANDARD CV | 5 |

|

GMAW, POWER MODE | 40 |

|

FCAW, STANDARD CV | 6 |

|

WAVEFORM CONTROL TECHNOLOGY |

| |

IR PORT | 5 | SETUP |

| STD CV MIG |

|

START OPTIONS |

|

| |

EFFECT / RANGE | DESCRIPTION | ||

|

|

| |

Preflow Time | Adjuststhe time that shielding gas | ||

0 - 25.0 seconds | flows after the trigger is pulled | ||

| and prior to feeding wire. | ||

wire fee d |

| ||

Off, 30 to150 in/min. | speed from the time the trigger | ||

| is pulled until an arc is estab- | ||

| lished. |

|

|

Start Procedure | The Start Procedure controls | ||

0 - 10 seconds | the WFS and Volts for a speci- | ||

| fied time at the beginni ng of | ||

| the weld. During the start time, | ||

| the mac hin e will ramp up o r | ||

| down from the Start Procedure | ||

| to the preset | Weldin g | |

| Procedure. |

|

|

|

|

| |

WELD MODE | START OPTIONS |

ARC CONTROL | END OPTIONS |

| SET |

EFFECT / RANGE | ARC CONTROL | |

| DESCRIPTION | |

PINCH |

| Pinch controls the arc characte- |

| ||

(Crisp)+10.0 |

|

|

END OPTIONS |

|

|

| ||

EFFECT / RANGE |

| DESCRIPTION |

| ||

|

|

|

|

| |

Spot Timer |

| Adju st t he time | we ldin g w ill |

| |

0 to 120.0 Seconds |

| contin ue e ve n if | th e t rigger |

| |

|

| is s till pu lle d. Thi s o ption |

| ||

|

| has n o e ff ect in |

| ||

|

| Trig ger Mo de. |

|

|

|

Postflow Time |

| Adjusts the time that shielding |

| ||

0 to 25.0 seconds |

| gas flows after the welding out- |

| ||

|

| put turns off. |

|

|

|

Crater Procedure |

| Crater Procedure controls the |

| ||

|

| ||||

0 TO 10.0 SECONDS |

| WFS and Volts for a specified |

| ||

|

| time at t he end of the weld |

| ||

|

| afte r the trig ger is | relea sed. |

| |

|

| Dur ing the Crat er | time, the |

| |

|

| machine will ramp up or down |

| ||

|

| from the Weld Procedure to |

| ||

Burnback: |

| the Crater Procedure. |

| ||

| The burn back ti me is t he |

| |||

0 to .25 Seconds |

| amount of time that the weld |

| ||

|

| output continues after the wire |

| ||

|

| stops feeding. It prevents the |

| ||

|

| wire from sticking in the puddle |

| ||

|

| and prepares the end of the |

| ||

|

| wire for the next arc start. |

| ||

|

|

|

|

|

|