OPERATION | ||

|

|

|

MAKING A WELD WITH WAVEFORM TECHNOLOGY POWER SOURCES

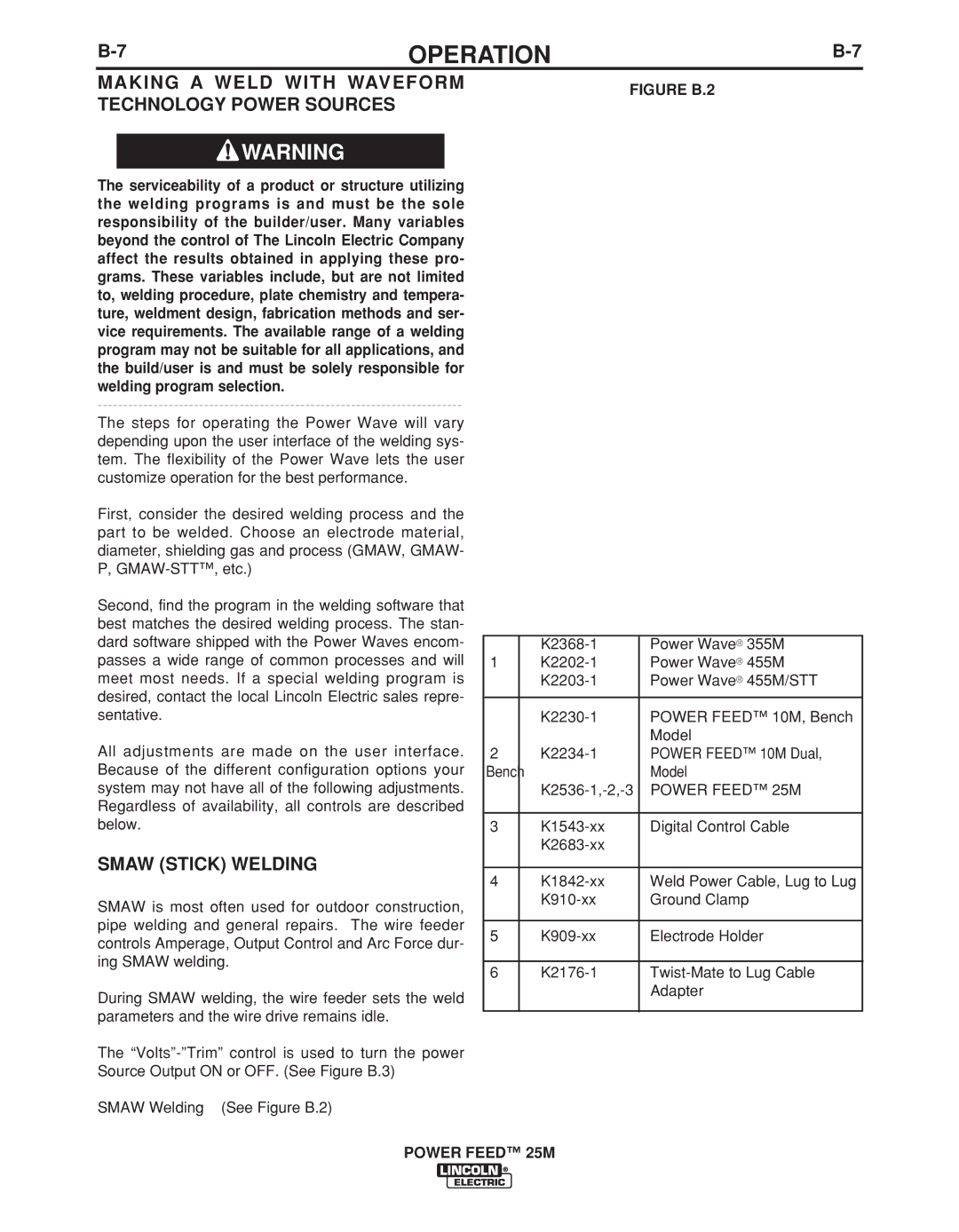

FIGURE B.2

![]() WARNING

WARNING

The serviceability of a product or structure utilizing the welding programs is and must be the sole responsibility of the builder/user. Many variables beyond the control of The Lincoln Electric Company affect the results obtained in applying these pro- grams. These variables include, but are not limited to, welding procedure, plate chemistry and tempera- ture, weldment design, fabrication methods and ser- vice requirements. The available range of a welding program may not be suitable for all applications, and the build/user is and must be solely responsible for welding program selection.

The steps for operating the Power Wave will vary depending upon the user interface of the welding sys- tem. The flexibility of the Power Wave lets the user customize operation for the best performance.

First, consider the desired welding process and the part to be welded. Choose an electrode material, diameter, shielding gas and process (GMAW, GMAW- P,

Second, find the program in the welding software that best matches the desired welding process. The stan- dard software shipped with the Power Waves encom- passes a wide range of common processes and will meet most needs. If a special welding program is desired, contact the local Lincoln Electric sales repre- sentative.

All adjustments are made on the user interface. Because of the different configuration options your system may not have all of the following adjustments. Regardless of availability, all controls are described below.

SMAW (STICK) WELDING

SMAW is most often used for outdoor construction, pipe welding and general repairs. The wire feeder controls Amperage, Output Control and Arc Force dur- ing SMAW welding.

During SMAW welding, the wire feeder sets the weld parameters and the wire drive remains idle.

The

SMAW Welding (See Figure B.2)

| WA |

|

|

|

|

|

| RN RNING |

|

|

|

|

|

1 | WA |

|

|

|

|

|

ING |

|

|

|

|

| |

| A | ATT |

|

|

| |

|

| PREVISOENTI |

|

| ||

|

|

| CAUCION |

|

| |

|

|

| DE | ON |

|

|

6 |

|

|

|

|

|

|

|

|

|

|

| 3 5 | 5 |

|

|

|

|

|

| |

|

|

|

| A V | E |

|

|

|

| W |

|

| |

|

| E R |

|

|

| |

| P O | W |

|

|

|

|

|

|

|

|

|

| |

4

3

|

| 5 |

2 |

|

|

| Power Wave® 355M | |

1 | Power Wave® 455M | |

| Power Wave® 455M/STT | |

| POWER FEED™ 10M, Bench | |

|

| Model |

2 | POWER FEED™ 10M Dual, | |

Bench |

| Model |

| POWER FEED™ 25M | |

3 | Digital Control Cable | |

|

| |

4 | Weld Power Cable, Lug to Lug | |

| Ground Clamp | |

5 | Electrode Holder | |

6 | ||

|

| Adapter |