OPERATION | ||

|

|

|

Peak

Current

Too Low

Background

Current

Too Low

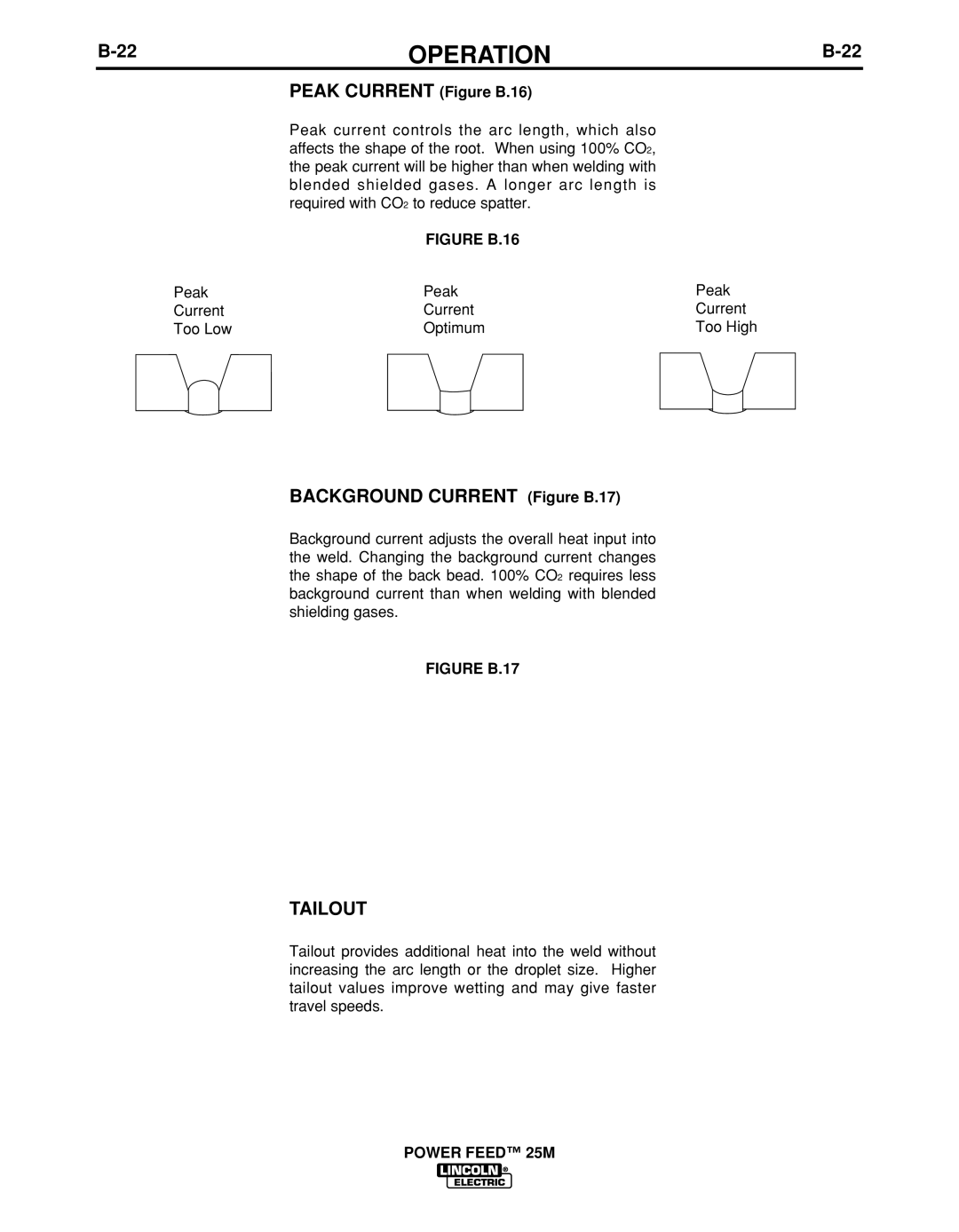

PEAK CURRENT (Figure B.16)

Peak current controls the arc length, which also affects the shape of the root. When using 100% CO2, the peak current will be higher than when welding with blended shielded gases. A longer arc length is required with CO2 to reduce spatter.

FIGURE B.16 |

|

Peak | Peak |

Current | Current |

Optimum | Too High |

BACKGROUND CURRENT (Figure B.17)

Background current adjusts the overall heat input into the weld. Changing the background current changes the shape of the back bead. 100% CO2 requires less background current than when welding with blended shielding gases.

FIGURE B.17

Background | Background |

Current | Current |

Optimum | Too High |

TAILOUT

Tailout provides additional heat into the weld without increasing the arc length or the droplet size. Higher tailout values improve wetting and may give faster travel speeds.